If you’ve ever stepped into an elevator that glides up smoothly and quietly, chances are — you were riding a traction elevator. It’s one of the most common elevator types found in office buildings, malls, and even modern homes. But how exactly does it work? Let’s break it down in plain English.

1. What Is a Traction Elevator?

A traction elevator uses steel ropes (or belts) and a motor-driven traction system to move the cabin up and down. Unlike hydraulic elevators, which rely on fluid pressure, traction elevators are powered by friction — that’s where the word “traction” comes from.

Think of it like this:

When the motor turns a wheel (called the sheave), it grips the ropes attached to the elevator car and counterweight. The ropes move in opposite directions — when the car goes up, the counterweight goes down, balancing the load.

This design makes traction elevators faster, more energy-efficient, and perfect for high-rise or mid-rise buildings.

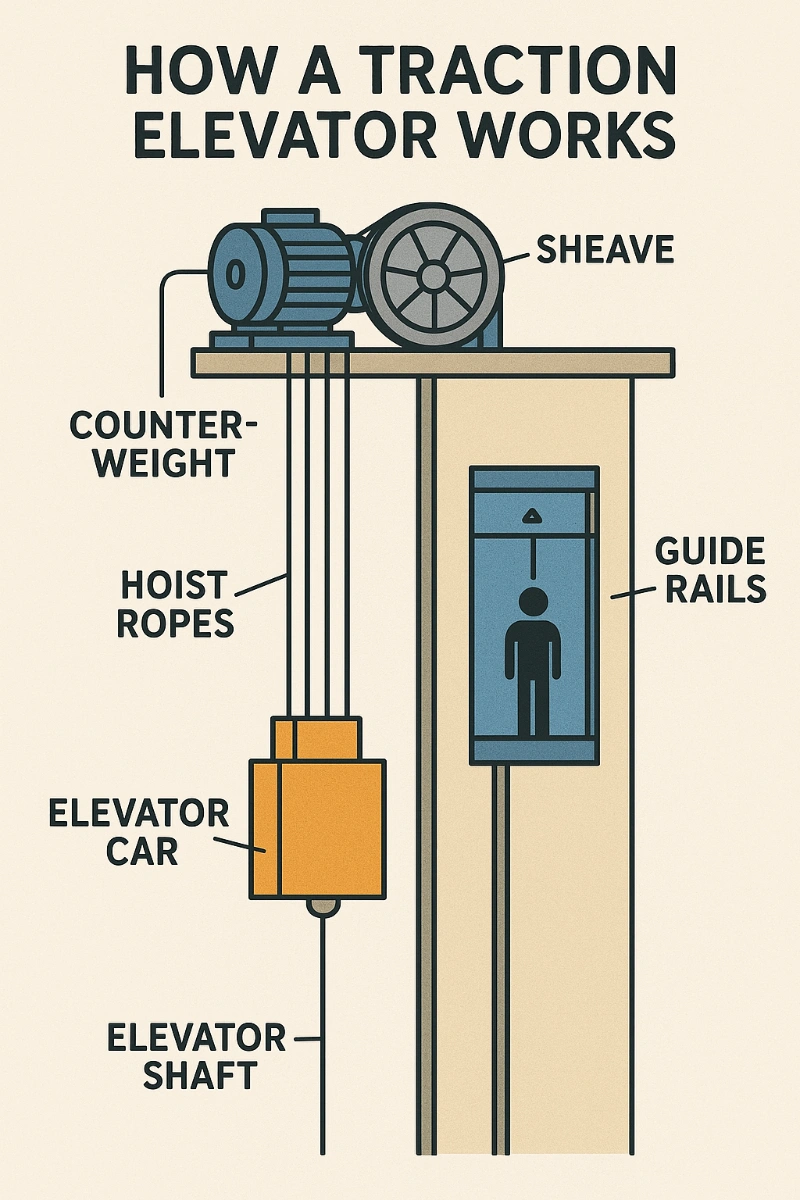

2. The Main Components

Let’s quickly go over the key parts that make everything work:

| Component | Function |

|---|---|

| Traction Sheave (Drive Wheel) | Grips and moves the ropes to lift or lower the car. |

| Steel Ropes or Belts | Connect the elevator car and counterweight. |

| Counterweight | Balances the car’s weight to reduce motor strain. |

| Gearless or Geared Motor | Powers the movement — gearless types are quieter and smoother. |

| Guide Rails | Keep the car and counterweight moving straight. |

| Controller | The elevator’s “brain” that manages speed, stopping, and direction. |

Each of these parts works together to make sure your elevator ride is safe, stable, and smooth.

3. The Working Principle (Step-by-Step)

Here’s a simple explanation of how a traction elevator works:

Step 1: The Call

You press the elevator button. The controller receives the signal and tells the motor to move.

Step 2: The Motor Spins the Sheave

The motor turns the sheave, which moves the steel ropes. Because the ropes are attached to both the elevator car and the counterweight, one goes up while the other goes down.

Step 3: Balance and Motion

The counterweight helps offset the car’s weight — usually about 40–50% of the car’s rated capacity. This makes it easier for the motor to move the elevator, using less energy.

Step 4: Speed Control

Modern traction elevators use Variable Voltage Variable Frequency (VVVF) drives to control motor speed smoothly. That’s why you don’t feel a sudden jerk when the elevator starts or stops.

Step 5: Braking and Stopping

When the car reaches the chosen floor, the motor slows down and the electromechanical brakes hold the sheave in position. The doors open automatically — and you’re there, safe and sound.

This is a diagram of how a traction elevator works.

4. Types of Traction Elevators

There are two main types:

1. Geared Traction Elevator

Uses a motor with a gearbox.

Typically runs at 150–500 feet per minute (0.75–2.5 m/s).

Ideal for mid-rise buildings up to 15–20 floors.

2. Gearless Traction Elevator

Direct connection between motor and sheave — no gears.

Speeds up to 2,000 feet per minute (10 m/s) or more.

Used in high-rise buildings and luxury residential lifts.

Smoother, quieter, and requires less maintenance.

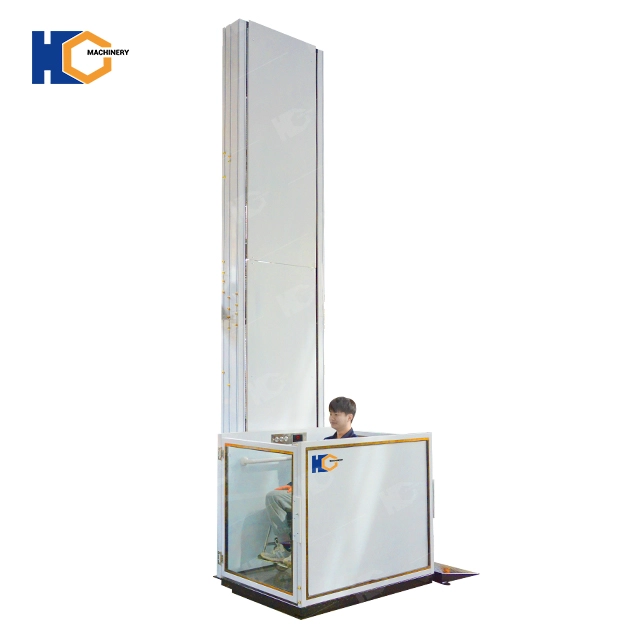

We currently offer two main traction elevator models: the K600 and the K900. To learn more about the K900 traction elevator, click here. Traction home elevator K900 lift manufacturer from China.

5. Why Traction Elevators Are So Popular

Here’s why most modern buildings prefer traction elevators:

✅ Energy Efficient – The counterweight reduces power use.

✅ Faster Travel – Perfect for multi-story buildings.

✅ Smooth Ride – No jerky starts or stops.

✅ Space-Saving Options – MRL (machine-room-less) designs fit into tighter shafts.

✅ Durable and Long-Lasting – With proper care, traction systems can last over 25 years.

6. Safety Features You Should Know

Modern traction elevators are packed with safety tech, including:

Overspeed governor — activates the safety brake if the car moves too fast.

Buffer system — cushions the car at the bottom of the shaft.

Emergency brakes — automatically hold the car in place if power fails.

Door sensors — prevent the doors from closing on passengers.

Backup power — ensures the car reaches the nearest floor during outages.

So yes — traction elevators aren’t just fast, they’re incredibly safe too.

7. Maintenance Tips for Traction Elevators

To keep things running smoothly:

Get professional monthly or quarterly maintenance.

Keep an eye on rope tension and brake systems.

Check for noise, vibration, or uneven stops — these can signal wear.

Clean and lubricate moving parts regularly.

Good maintenance ensures a quiet, efficient, and long-lasting system.

8. Choosing Between Traction and Hydraulic Elevators

If you’re deciding which elevator type to buy, here’s a quick comparison:

| Feature | Traction Elevator | Hydraulic Elevator |

|---|---|---|

| Speed | Faster | Slower |

| Energy Use | Lower (with counterweight) | Higher |

| Ideal For | Mid to high-rise | Low-rise |

| Ride Smoothness | Very smooth | Moderate |

| Maintenance | Slightly higher | Easier |

| Cost | Higher upfront | Lower initial cost |

So, if your building has more than 3–4 floors, a traction elevator is usually the smarter choice. For smaller homes or low-rise buildings, hydraulic elevators might be more cost-effective.To learn more about Traction Elevator vs Hydraulic Elevator: What’s the Difference and How to Choose?, please read this article.

9. Final Thoughts

In simple terms, a traction elevator works through balance and motion — the car and counterweight dance up and down, powered by a motor that uses friction to move the ropes. The result is a fast, smooth, and energy-efficient lift system that’s stood the test of time.

Whether you’re designing a new building or upgrading your current one, understanding how traction elevators work helps you make a smarter, safer investment.

812.webp)