Scissor lifts, one of the cornerstones in vertical access platforms, have revolutionized worksite efficiency, safety, and versatility in modern industrial and construction environments. Yet, not all scissor lifts are created equal. With a wide variety of types flooding the market, understanding how to classify and evaluate them through multiple dimensions becomes crucial for both end-users and industry professionals. In this article, we dissect scissor lifts through a comprehensive lens—classifying them by purpose, structure, and performance—and spotlight Jinan Huichuang Machinery Manufacturing Co., Ltd. (Huichuang Lift), a leading lift solutions provider from China.

Classification by Usage: Matching Machines to Tasks

At the core of any selection decision lies the Usage. The context in which a scissor lift will be deployed determines the key features needed.

| Usage | Recommended Type | Application Example |

|---|---|---|

| Indoor Maintenance | Self-Propelled Electric Scissor Lift | Ceiling work, electrical repairs |

| Outdoor Construction | Towable or Crawler Scissor Lift | Steel erection, bridgework |

| Warehouse & Logistics | Mobile Scissor Lift | Inventory picking, shelving |

| Residential Accessibility | Fixed Scissor Lift / Home Lift | Wheelchair access, multi-floor use |

Self-propelled electric scissor lifts are perfect for indoor environments requiring low noise and emissions, while crawler and towable models are tailored for rugged terrain and mobility between sites. Fixed scissor lifts, on the other hand, offer long-term stability in stationary applications such as loading bays or residential buildings. Huichuang Lift provides all of these categories, catering to specialized and general-purpose needs with bespoke engineering solutions.

Crawler Scissor Lift

Structural Differences: Mechanical Design & Engineering Nuances

A scissor lift’s structure is not merely aesthetic; it directly affects stability, lifting height, payload, and mobility. The lifting mechanism, material quality, and base configuration are the key factors.

| Structure Type | Characteristics | Best For |

| Mobile Scissor Lift | Portable, easy to deploy | Warehousing, workshops |

| Towable Scissor Lift | Trailer-mounted, transportable | Multi-site construction |

| Self-Propelled Scissor Lift | Drivable, battery-powered mobility | Indoor and large flat surface work |

| Crawler Scissor Lift | Tracked base for rough terrain | Uneven ground, outdoor maintenance |

| Fixed Scissor Lift | Stationary, reliable, strong base | Loading docks, residential lifts |

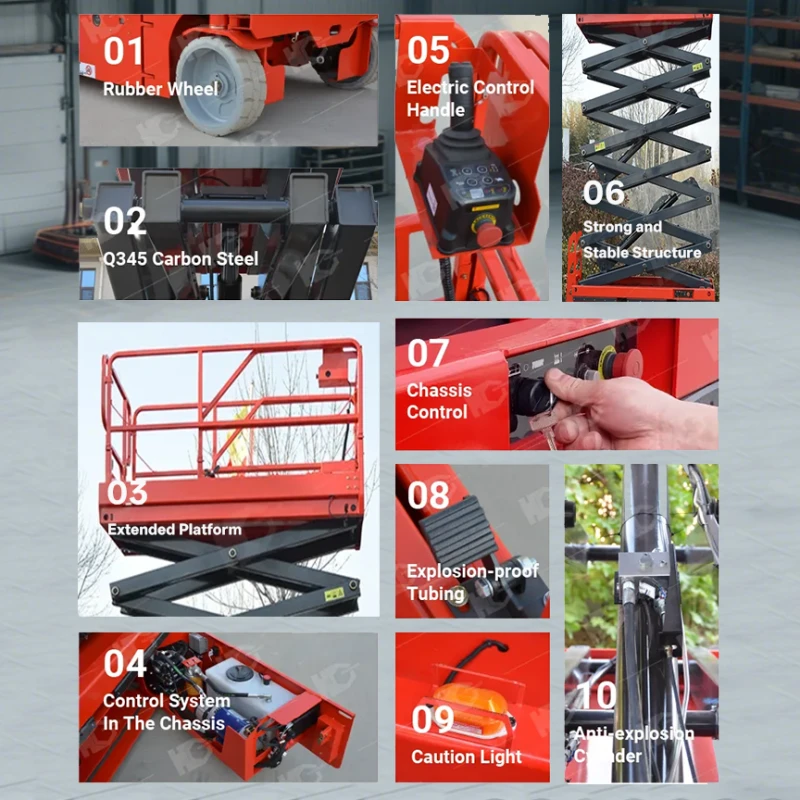

Huichuang Lift manufactures a range of structural configurations, all built with enhanced durability and safety mechanisms, such as overload sensors and anti-drop devices. Their multi-scissor platforms are especially notable for achieving greater elevation without increasing the equipment footprint—a subtle but significant engineering advantage.

Performance Parameters: Beyond Just Lifting

Performance doesn’t stop at height and load capacity. In fact, scissor lifts are now evaluated on an expanded matrix including speed, energy consumption, safety features, and terrain adaptability.

| Performance Factor | High-Performance Benchmark | Huichuang Lift Offering |

| Max Lifting Height | Up to 20 meters | 4 to 18 meters (customizable) |

| Load Capacity | 230kg to over 1000kg | 300kg to 1000kg+ |

| Drive Type | Electric, Diesel, Hybrid | Full spectrum |

| Terrain Compatibility | Rough terrain, paved indoor surfaces | Non-marking tires, four-wheel drive |

| Safety Systems | Emergency stop, tilt alarms, fall arrest bars | CE, ISO, ASME A17.1 compliant |

The performance versatility of Huichuang Lift is underscored by their ability to combine ruggedness with refinement. One of their flagship models features dual power systems (electric + diesel) that automatically switch depending on environmental needs—a testament to their forward-thinking R&D capabilities.

Application-Specific Customization: Meeting Real-World Demands

One of Huichuang Lift’s standout strengths lies in its ability to deliver targeted solutions for unique operational environments. Whether you’re operating in a compact warehouse, a muddy construction site, or a multi-floor residential setting, Huichuang’s lineup offers tailored features.

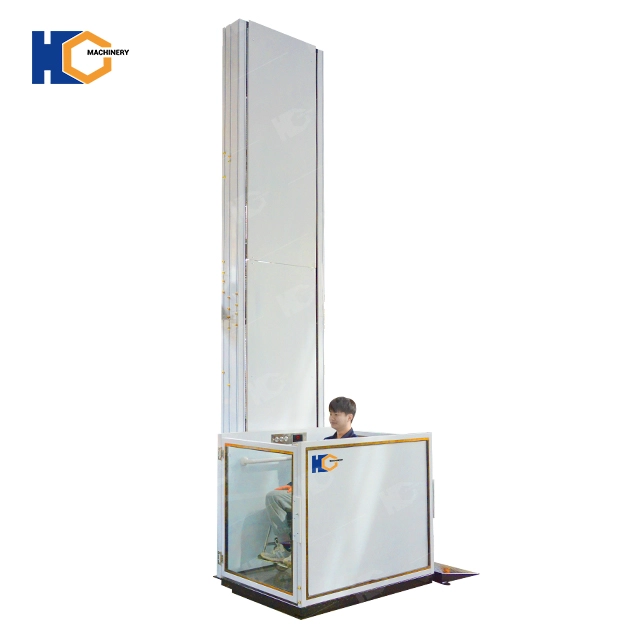

For example, the crawler scissor lift can be equipped with extended platforms and anti-skid steel decks for forestry and mining sectors. In contrast, the fixed scissor lift often includes smooth, silent hydraulic systems that are ideal for residential access installations in villas and buildings. This adaptability not only ensures functional precision but also makes procurement more value-driven.

Fixed scissor lift

User Experience and Ease of Operation

While performance data and engineering specs are essential, the actual day-to-day usability often defines long-term satisfaction. Huichuang Lift integrates intuitive control panels, ergonomic handrails, and safety interlocks across all models. For example, the self-propelled scissor lift comes with joystick control, fault diagnosis display, and automatic pothole protection—all designed to minimize the learning curve while maximizing productivity.

Their towable models also include user-friendly hitching systems and stabilizer outriggers that allow for quick deployment. For residential users, the fixed lift’s control interface can be designed with simple up/down buttons, touchscreens, or even voice activation for elderly users.

Serviceability and After-Sales Support

A superior machine is only as good as the support it receives post-purchase. That’s why Huichuang Lift invests heavily in its after-sales service system. Customers benefit from detailed user manuals, on-site installation guidance, and remote troubleshooting.

Spare parts are shipped globally with minimal delay, and an OEM service allows clients to stock essential maintenance kits for faster repair cycles. Additionally, Huichuang offers training programs for operators and technicians—fostering better long-term performance and safety.

Self-Propelled Electric Scissor Lift

Comparative Cost Analysis: Budget vs. Value

It's tempting to go for the cheapest option, especially for short-term use. But a closer inspection of the cost-performance ratio often reveals deeper truths.

| Type | Average Price Range (USD) | Lifespan (Years) | Maintenance Frequency | Value for Money |

| Mobile Scissor Lift | $6,000 - $10,000 | 8 - 10 | Low | Excellent mobility |

| Towable Scissor Lift | $8,000 - $15,000 | 10 - 12 | Medium | Flexible deployment |

| Self-Propelled Electric | $12,000 - $25,000 | 8 - 10 | Low | High indoor ROI |

| Crawler Scissor Lift | $18,000 - $30,000 | 10 - 15 | Medium | Terrain versatility |

| Fixed Scissor Lift | $3,000 - $10,000 | 10 - 15 | Low | Best for fixed use |

Please contact the supplier for specific prices.

Huichuang Lift strikes a commendable balance here. By leveraging in-house production and optimized logistics, they provide competitively priced units that don’t skimp on performance. Moreover, their OEM service ensures that buyers can customize features while maintaining price parity with mass-market alternatives.

Compliance and Safety: The Unseen Backbone

In an era where regulatory compliance is non-negotiable, safety features and certifications are not just marketing fluff; they are essential safeguards.

| Safety Feature | Importance | Huichuang Implementation |

| Emergency Lowering System | Allows safe descent during power failure | Standard on all models |

| Tilt Sensor | Prevents operation on unsafe angles | Integrated with alarm systems |

| Overload Protection | Prevents structural and motor damage | Sensor-based cutoff |

| Guard Rails & Toe Boards | Protect workers at elevation | Industrial-grade steel construction |

Huichuang Lift meets CE, ISO, and ASME A17.1 standards, ensuring global compliance. Their engineering ethos places user safety at the forefront, supported by a rigorous QC pipeline and multiple fail-safes.

Future Trends and Innovation: Where Are Scissor Lifts Heading?

With the rising tide of automation, IoT integration, and sustainability, the scissor lift industry is entering a phase of intelligent transformation. Expect features like remote diagnostics, app-based controls, lithium-ion battery systems, and modular construction for easier repairs.

Huichuang Lift has already begun R&D into smart control systems and AI-driven diagnostics, laying the groundwork for the next generation of scissor lifts. Their commitment to innovation mirrors their broader mission: to create more possibilities and build accessibility for all.

Why Choose Huichuang Lift: A Partner Beyond Products

At a glance, you might see a machine. But behind every Huichuang Lift product lies a deep commitment to problem-solving, performance, and people. With over 200 dedicated staff members, advanced workshops, and a global sales footprint, Huichuang isn’t just selling lifts; they’re building trust.

Their reputation for reliability, responsiveness, and resilience has made them a top choice for customers from North America to Southeast Asia. Whether you're looking to enhance industrial efficiency or provide accessible home solutions, Huichuang Lift has the expertise and flexibility to support your goals. If necessary, please contact Huichuang Lift.

812.webp)