When it comes to vertical transportation in buildings, the debate between hydraulic elevators and traction elevators never seems to lose steam. Whether you're a property developer, a facility manager, or simply curious about elevator technologies, understanding the real cost differences between hydraulic and traction elevators is vital—not just the purchase price, but long-term expenses, maintenance implications, energy consumption, and overall return on investment.

649630.webp)

Hydraulic Elevators vs Traction Elevators: What's the Difference?

Before diving head-first into the costs, it's worth briefly clarifying the technical differences:

Hydraulic Elevators: These systems rely on hydraulic fluid and pistons to lift the elevator cab. Generally, they're ideal for low to mid-rise buildings (typically up to 5-6 stories). They're known for their simplicity, relatively lower initial installation costs, and quiet operation at lower speeds.

Traction Elevators: These use steel ropes, counterweights, and motors to move the cab. Traction elevators are commonly installed in mid to high-rise buildings due to their efficiency, speed, and space-saving shaft requirements.

Now, let’s unpack the real meat of the discussion: the costs involved.

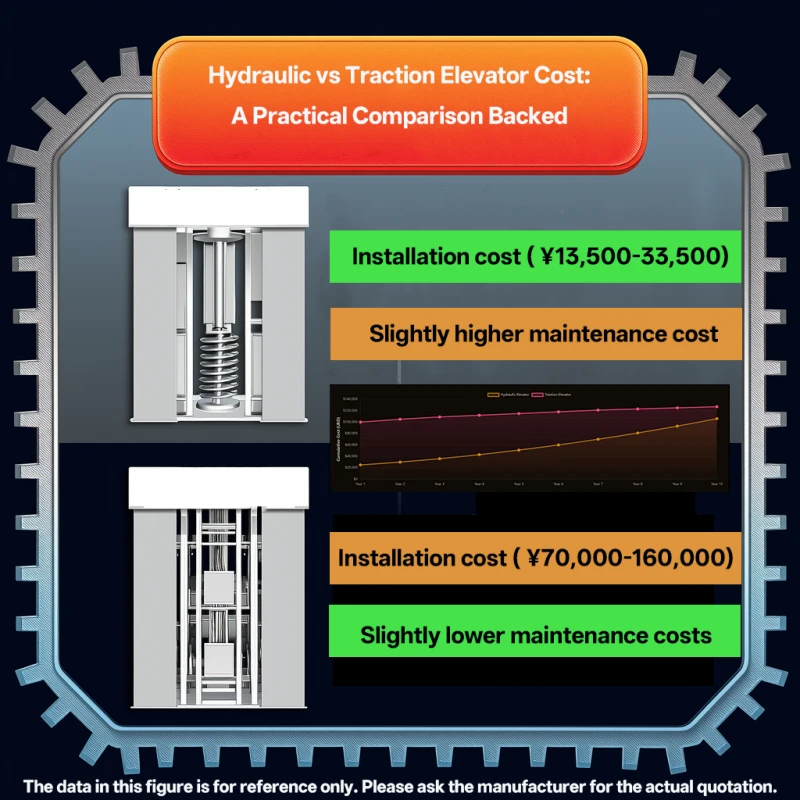

1. Initial Installation Cost Comparison

| Elevator Type | Typical Building Height | Estimated Installation Cost (USD) |

|---|---|---|

| Hydraulic Elevator | 2 to 6 floors | $30,000 - $80,000 |

| Traction Elevator | 5 floors and above | $50,000 - $150,000+ |

Hydraulic elevators have the reputation for being easier and cheaper to install—less complex shaft requirements, no overhead machine rooms in some configurations, and simpler mechanical components. In contrast, traction elevators often demand more elaborate infrastructure, especially for higher-rise applications.

That said, if you’re considering only the upfront bill, hydraulic elevators might look tempting. But… as with many things, the story evolves when long-term ownership costs enter the chat.

446051.webp)

2. Energy Consumption and Operational Costs

An area where traction elevators pull ahead is energy efficiency, particularly with gearless traction models using regenerative drives. Let’s stack up the numbers:

| Elevator Type | Average Annual Energy Cost (USD) | Notes |

| Hydraulic Elevator | $1,200 - $2,500 | Energy-intensive due to pumping system |

| Traction Elevator | $800 - $1,800 | More efficient, especially with modern regenerative tech |

The hydraulic system consumes more energy, especially during lifting operations. The counterweight system in traction elevators significantly reduces the motor’s workload, translating to lower electricity bills over time.

3. Maintenance and Lifespan Considerations

Maintenance costs are an often-overlooked but critical part of elevator budgeting. Here's where things get nuanced:

| Elevator Type | Typical Lifespan | Annual Maintenance Cost (USD) | Common Issues |

| Hydraulic Elevator | 20-25 years | $2,000 - $4,000 | Hydraulic fluid leaks, piston wear, control system aging |

| Traction Elevator | 25-30 years | $2,500 - $5,000 | Rope wear, motor servicing, advanced control calibration |

While hydraulic elevators tend to have simpler mechanics, they require frequent attention to components like hydraulic fluid quality and seals. On the other hand, traction elevators, especially those with advanced control systems, may demand specialized technicians—raising maintenance costs but offering longer operational life.

4. Space Requirements and Construction Impact

In building design, space is money. Traction elevators often offer advantages with:

No need for machine rooms (for Machine Room-Less or MRL models)

More flexible shaft dimensions

Higher usable building space

Hydraulic elevators generally require a dedicated machine room and deeper pit construction, which could offset initial savings when considering real estate costs in premium urban environments.

295803.webp)

5. Real-World Case Study: Huichuang Lift's Perspective

As a recognized leader in the lift industry, Jinan Huichuang Machinery Manufacturing Co., Ltd. (Huichuang Lift) has seen the shifting tides of elevator preferences firsthand. Based in Jinan, the "Hometown of Hydraulic Lifting Platforms," we specialize in both hydraulic and home elevator solutions, catering to a diverse global market.

Our experience shows that clients seeking cost-effective, reliable solutions for low-rise residential or commercial buildings often lean toward hydraulic elevators. Their lower upfront cost, straightforward design, and easier maintenance resonate with small building owners, particularly in Southeast Asia and parts of Europe.

Conversely, for mid to high-rise structures, our customers—from North America to South America—increasingly prefer traction systems for their efficiency, longevity, and modern energy-saving features.

6. Hidden Costs and Long-Term Value

Beyond the obvious price tags, subtle costs often creep into the equation:

Downtime Costs: Hydraulic elevators may suffer more frequent downtime due to fluid leaks or piston wear. Lost productivity in commercial settings translates to financial impact.

Modernization Expenses: Upgrading hydraulic systems to meet evolving codes or efficiency standards can be pricier over time.

Environmental Impact: Hydraulic fluid disposal and potential leakage pose environmental concerns. Traction systems, especially with regenerative drives, align better with sustainability goals.

7. Summary Cost Breakdown Over 25 Years

| Cost Component | Hydraulic Elevator | Traction Elevator |

| Initial Installation | $50,000 | $90,000 |

| Energy Consumption | $45,000 | $30,000 |

| Maintenance | $75,000 | $87,500 |

| Modernization/Upgrades | $20,000 | $15,000 |

| Total Estimated Cost | ~$190,000 | ~$222,500 |

Note: Real costs fluctuate by region, building specifics, and supplier. But this model gives a directional snapshot.

8. Conclusion: The Choice Depends on Your Priorities

Choosing between hydraulic and traction elevators isn't purely a numbers game—it’s about matching technology to application.

Go Hydraulic if: You’re installing in a low-rise building, need budget-friendly options upfront, or prioritize straightforward maintenance.

Opt for Traction if: Energy efficiency, long-term performance, higher speeds, and space optimization matter more.

At Huichuang Lift, we pride ourselves on providing tailored solutions, whether it's our robust hydraulic aerial work platforms or efficient home elevators—all backed by global certifications like CE, ISO, and ASME A17.1.

Our mission? To deliver hassle-free lifting experiences, boost building accessibility, and partner with forward-thinking service providers worldwide. If you're considering an elevator solution—whether hydraulic, traction, or beyond—contact Huichuang Lift to explore safe, efficient, and cost-effective options designed for your unique project.

Disclaimer: The data presented is based on industry averages and independent research. For precise project quotations, consult your elevator supplier.

Huichuang Lift is recruiting global agents, welcome to leave us a message.