Electric mobile scissor lift tables are essential material-handling platforms designed to safely elevate workers, tools, and loads in industrial, commercial, and construction settings. Powered by efficient electric motors, these lifts feature a crisscross "scissor" mechanism that provides stable vertical movement, making them ideal for repetitive lifting tasks in warehouses, manufacturing plants, retail spaces, and logistics centers. Unlike traditional forklifts, they offer precise height adjustment, compact maneuverability, and often include safety features like guardrails, non-slip platforms, and emergency stop controls. Their versatility allows for applications ranging from stock replenishment and equipment maintenance to assembly line work and event staging.

The price of an electric mobile scissor lift table can vary significantly—typically ranging from $1,500 for basic models to over $20,000 for heavy-duty units—depending on several key factors. Load capacity is a primary driver, with entry-level models handling 500–1,000 lbs, while industrial-grade lifts support 2,000–5,000+ lbs. Lift height also impacts cost; tables with 3–6 ft ranges are economical, whereas models extending to 15–20 ft command premium pricing. Brand reputation plays a role too (e.g., Genie or JLG vs. generic brands), as do features like hydraulic vs. electric operation, battery life, portability (wheel types or compact designs), and advanced controls (wireless remotes or programmable settings). Additional expenses like certifications (OSHA/ANSI compliance), customization, or weatherproofing for outdoor use can further influence the final price.

*"Prices range from $1,500 to $20,000+—here’s what affects the cost."* Whether you need a budget-friendly lift for light-duty tasks or a high-capacity model for demanding environments, understanding these variables ensures a smart investment. In this guide, we’ll break down pricing tiers, compare top brands, and reveal how to maximize value without compromising safety or performance.

Electric Mobile Scissor Lift Table Price Range (2025)

Electric mobile scissor lift tables come in various price tiers depending on their load capacity, build quality, and features. Below is a detailed breakdown of the average price ranges for entry-level, mid-range, and premium models, along with their key specifications.

1. Entry-Level Models ($1,500 – $5,000)

Designed for light-duty applications, these lifts are cost-effective for small businesses or occasional use.

Load Capacity: 500 – 1,000 lbs

Lift Height: 3 – 6 feet

Features: Manual controls, basic safety rails, stationary or small wheels

Best For: Warehouses, retail stock rooms, small workshops

2. Mid-Range Models ($5,000 – $12,000)

These offer better durability and higher performance, suitable for frequent industrial use.

Load Capacity: 1,000 – 2,500 lbs

Lift Height: 6 – 12 feet

Features: Electric/hydraulic operation, reinforced platforms, OSHA-compliant safety

Best For: Manufacturing plants, construction sites, logistics centers

3. Premium Models ($12,000 – $20,000+)

Heavy-duty lifts with advanced engineering for demanding industrial environments.

Load Capacity: 2,500 – 5,000+ lbs

Lift Height: 12 – 20+ feet

Features: Customizable platforms, wireless controls, all-terrain mobility

Best For: Large-scale construction, aerospace, automotive industries

Price Comparison Table (2025)

| Model Tier | Price Range | Load Capacity | Max Height | Key Features |

|---|---|---|---|---|

| Entry-Level | $1,500 – $5,000 | 500 – 1,000 lbs | 3 – 6 ft | Basic controls, compact design |

| Mid-Range | $5,000 – $12,000 | 1,000 – 2,500 lbs | 6 – 12 ft | OSHA compliance, durable construction |

| Premium | $12,000 – $20,000+ | 2,500 – 5,000+ lbs | 12 – 20+ ft | Advanced safety, customization options |

Choosing the Right Model

Budget-conscious buyers: Entry-level lifts are sufficient for light tasks.

Frequent industrial use: Mid-range offers the best balance of cost and durability.

Heavy-duty needs: Premium models ensure long-term reliability and safety.

This pricing guide helps businesses make informed decisions based on workload, safety requirements, and budget. For exact quotes, consult manufacturers or authorized dealers.

Key Factors Affecting Electric Mobile Scissor Lift Table Costs (2025)

When purchasing an electric mobile scissor lift table, understanding the key factors that influence pricing ensures you get the best value for your needs. Prices can vary significantly—from $1,500 for basic models to over $20,000 for heavy-duty lifts—depending on these critical elements:

1. Load Capacity (500 lbs vs. 2,000+ lbs)

The weight a lift can support is one of the biggest cost determinants.

Entry-Level (500–1,000 lbs): $1,500–$5,000

Ideal for light warehouse or retail use (e.g., stocking shelves).Mid-Range (1,000–2,500 lbs): $5,000–$12,000

Suits most industrial tasks (manufacturing, construction).Heavy-Duty (2,500–5,000+ lbs): $12,000–$20,000+

Required for automotive, aerospace, or large-scale material handling.

Pro Tip: Overestimating capacity needs by 20% ensures longevity and safety.

2. Lift Height (3 ft vs. 20 ft)

Higher lifts require stronger materials and complex engineering.

Low Height (3–6 ft): Affordable ($1,500–$5,000), common in workshops.

Medium Height (6–12 ft): Mid-range pricing ($5,000–$12,000), used in warehouses.

High Reach (12–20+ ft): Premium cost ($12,000+), essential for construction or maintenance.

Safety Note: Lifts above 10 ft often need OSHA-compliant guardrails, adding to costs.

3. Power Source (Battery, AC/DC, Hybrid)

Battery-Powered: $2,000–$15,000

Offers mobility but requires charging; runtime varies (4–8 hours).AC/DC Electric: $3,000–$10,000

Plug-in models provide consistent power but limit movement.Hybrid: $8,000–$20,000+

Combines fuel and electric for versatility in outdoor/indoor use.

Best For: Warehouses favor batteries; construction sites may need hybrids.

4. Mobility & Portability

Fixed vs. Mobile: Mobile lifts cost 20–30% more due to wheels/tires.

Wheel Types:

Polyurethane ($1,500–$5,000): Indoor use.

Pneumatic ($3,000–$10,000): Rough terrain.

Compact Designs: Narrow or foldable lifts (e.g., for tight spaces) add 10–15% to the price.

5. Brand Reputation

Premium Brands (Genie, JLG, Snorkel): $10,000–$20,000+

Higher reliability, better warranties, and compliance certifications.Budget Brands: $1,500–$8,000

May lack durability or after-sales support.

Trade-Off: Mid-tier brands (e.g., Haulotte, Skyjack) offer a balance at $7,000–$15,000.

6. Additional Features

Hydraulic vs. Electric: Hydraulic lifts ($5,000–$15,000) handle heavier loads but require more maintenance than electric ($3,000–$12,000).

Safety Features: OSHA compliance adds $500–$2,000 (e.g., fall arrest systems, emergency stops).

Advanced Controls: Wireless remotes or programmable settings increase costs by 10–20%.

Customization: Powder coating, extended platforms, or weatherproofing can add $1,000–$5,000.

Cost-Saving Tips

Buy Refurbished: Save 30–50% on certified pre-owned lifts.

Prioritize Needs: Avoid overpaying for unnecessary height/capacity.

Compare Quotes: Prices vary by distributor; negotiate bulk discounts.

While upfront cost matters, consider long-term expenses (maintenance, downtime) when choosing between budget and premium models.

Popular Electric Mobile Scissor Lift Table Brands & Price Comparisons (2025)

When investing in an electric mobile scissor lift table, brand reputation significantly impacts quality, safety, and long-term value. Below is a comparison of top-tier brands and budget-friendly alternatives, along with their price ranges and key features.

1. Premium Brands (High-End Performance & Reliability)

Genie

Price: $15,000 – $30,000+

Why Buy? Industry-leading durability, advanced safety features, and excellent customer support.

Best For: Heavy-duty construction, aerospace, and large-scale industrial use.

Haulotte

Price: $12,000 – $25,000

Why Buy? European-engineered precision, hybrid power options, and superior stability.

Best For: Warehousing, manufacturing, and outdoor applications.

Skyjack

Price: $10,000 – $20,000

Why Buy? Reliable mid-range lifts with OSHA compliance and easy maintenance.

Best For: Construction sites and logistics centers.

2. Budget-Friendly Alternatives (Cost-Effective Solutions)

Roughneck (Northern Tool)

Price: $3,000 – $8,000

Trade-Offs: Limited lift height (under 10 ft) and lower load capacity (up to 1,000 lbs).

Best For: Small workshops, retail, and light warehouse tasks.

Titan (Global Industrial)

Price: $2,500 – $7,000

Trade-Offs: Basic features, fewer safety certifications.

Best For: Occasional use in garages or event staging.

Price Comparison Table

| Brand | Price Range | Load Capacity | Max Height | Best Use Case |

|---|---|---|---|---|

| Genie | $15K – $30K+ | 2,500 – 5,000+ lbs | 20+ ft | Heavy industrial |

| Haulotte | $12K – $25K | 1,500 – 4,000 lbs | 15–18 ft | Warehousing/Outdoor |

| Skyjack | $10K – $20K | 1,000 – 3,500 lbs | 12–16 ft | Construction |

| Roughneck | $3K – $8K | 500 – 1,000 lbs | 6–10 ft | Light-duty |

| Titan | $2.5K – $7K | 500 – 800 lbs | 4–8 ft | DIY/Small business |

Choosing the Right Brand

Prioritize Safety & Longevity? Genie or Haulotte.

Need Mid-Range Quality? Skyjack offers the best balance.

Tight Budget? Roughneck or Titan for light, infrequent use.

Pro Tip: Always check for warranty coverage and local dealer support before purchasing.

Hidden Costs of Electric Mobile Scissor Lift Tables (2025 Buyers Guide)

While the sticker price of an electric scissor lift table is important, smart buyers must budget for these often-overlooked expenses:

1. Shipping & Installation ($500–$5,000+)

Freight Charges: Large lifts may require specialized transport (10–20% of unit cost)

Assembly Fees: Professional installation adds $200–$1,000 (critical for OSHA compliance)

Site Prep: Electrical upgrades or floor reinforcement can cost extra

Pro Tip: Always request shipping quotes upfront—some suppliers offer "delivered to dock" pricing.

2. Maintenance & Spare Parts ($300–$3,000/year)

Routine Service: Annual inspections/maintenance contracts run $200–$1,500

Battery Replacement: $400–$1,200 every 3–5 years for electric models

Wear Parts: Hydraulic seals, wheels, and control pads add recurring costs

Critical Fact: Premium brands (Genie/Skyjack) often have lower long-term maintenance costs.

3. Training & Certification ($150–$1,500 per operator)

OSHA Compliance: Required operator training courses cost $150–$500/person

In-House Certification: Developing your own program costs $1,000+ initially

Recertification: Needed every 3 years (25–50% of initial training cost)

Safety Note: Untrained operators risk $15,000+ OSHA fines per violation.

Total Hidden Cost Estimate:

| Expense Category | Low Range | High Range | Frequency |

|---|---|---|---|

| Shipping/Install | $500 | $5,000 | One-time |

| Annual Maintenance | $300 | $3,000 | Yearly |

| Operator Training | $150 | $1,500 | Per person |

Smart Buying Advice:

Negotiate "turnkey" pricing including delivery/install

Compare warranty terms (look for 3+ years on critical components)

Factor in training costs when budgeting workforce expansion

These hidden expenses typically add 15–30% to your total investment—plan accordingly to avoid surprises.

Where to Buy Electric Mobile Scissor Lift Tables & How to Save (2025 Guide)

Finding the right supplier for your electric scissor lift table can significantly impact both upfront costs and long-term value. Here’s a breakdown of purchasing options, including how to secure the best deals:

1. Direct Manufacturers vs. Distributors

Direct from Manufacturers (Like JNHC LIFT – China-Based Supplier)

Pros: Lowest prices (no middleman markups), customization options, better warranty support

Cons: Longer lead times for international shipping, potential language barriers

Best For: Businesses buying in bulk or needing tailored solutions

Authorized Distributors

Pros: Faster local delivery, in-person demos, easier returns

Cons: 15–30% price premium over factory-direct

Best For: Single-unit buyers prioritizing convenience

2. Used & Refurbished Options

Pros:

Cost savings (40–60% off new models)

Certified refurbished units often include warranties (e.g., 1-year coverage)

Cons:

Limited lifespan/shorter warranty

May lack modern safety features

Smart Buy Tip: Look for ISO-certified refurbishers or OEM-reconditioned lifts.

3. Seasonal Discounts & Bulk Deals

Best Times to Buy:

Year-end (November–January) – Clearance sales

Trade shows (often feature show specials)

Bulk Purchase Savings:

Ordering 3+ units from manufacturers like JNHC LIFT can secure 5–15% discounts

Some suppliers offer free shipping on large orders

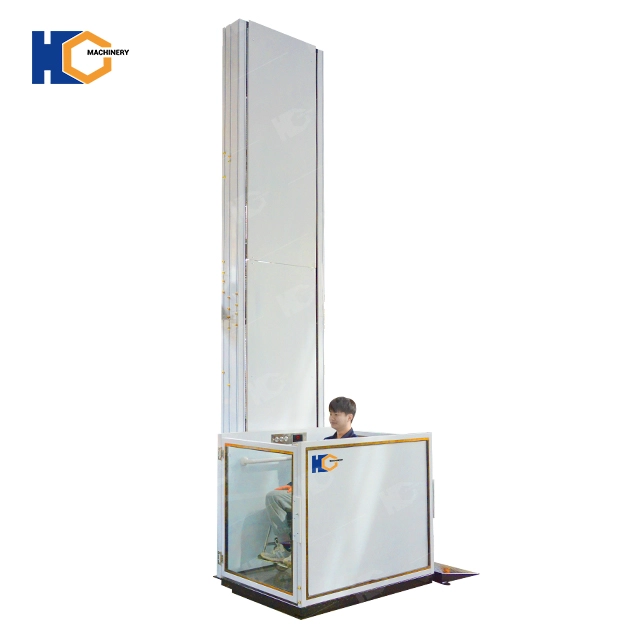

Why Consider JNHC LIFT?

As a direct Chinese manufacturer, JNHC LIFT provides:

✅ Factory prices (typically 20–40% lower than Western brands)

✅ Customizable options (platform size, power type, controls)

✅ CE/ISO certification for export quality

Sample Cost Comparison:

| Supplier Type | Price Range (1,000 lb capacity) | Lead Time |

|---|---|---|

| Western Distributor | $8,000–$12,000 | 2–4 weeks |

| JNHC LIFT (Direct) | $4,500–$6,500 | 6–8 weeks |

Final Tips to Save:

Request FOB pricing to compare shipping costs accurately

Ask about payment terms (TT/LC discounts)

Inquire about accessory bundles (free tools or spare parts)

For budget-conscious buyers without urgent needs, factory-direct purchases from trusted manufacturers like JNHC LIFT offer the best value long-term. Always verify supplier credentials with third-party inspections if buying internationally.

FAQs About Electric Mobile Scissor Lift Table Pricing (2025)

1. Is a cheaper scissor lift table worth it?

It depends on your usage:

Worth it for: Light, occasional tasks (e.g., stockroom use <5 hours/week). Budget models ($1,500–$5,000) work but may lack durability.

Not worth it for: Daily industrial use—cheaper lifts cost more long-term due to repairs/downtime.

2. Can I rent instead of buying?

Rental vs. Purchase Cost Comparison:

| Option | Cost | Best For |

|---|---|---|

| Renting | $150–$500/week | Short-term projects (<3 months) |

| Buying | $1,500–$20,000+ | Frequent use (>6 months/year) |

| Tip: Calculate break-even points—if rental fees exceed 50% of purchase price within a year, buying is smarter. |

3. How long do these lifts last?

Lifespan by Price Tier:

Budget ($1.5K–$5K): 3–5 years (with light use)

Mid-Range ($5K–$12K): 7–10 years

Premium ($12K+): 10–15+ years

Key Factor: Proper maintenance doubles lifespan.

4. What’s the warranty coverage like?

Budget Brands: 1-year limited (often excludes wear parts)

Premium Brands: 3–5 years (Genie/JLG cover structural components)

Always check: Battery/hydraulic system coverage terms.

5. Are used lifts a good deal?

Pros: Save 30–60%; Cons: Risk hidden wear.

Buy Safely:

✔ Only from certified refurbishers

✔ With inspection reports

✔ Avoid models >5 years old

6. How much does maintenance cost annually?

Basic Service: $200–$500 (lubrication, inspections)

Full Tune-Up: $800–$1,500 (hydraulic/battery overhaul)

Save Money: Learn DIY checks (fluid levels, bolt tightness).

7. Do I need operator training/certification?

OSHA Requires Training for lifts over 6 ft (~$150–$500/person).

Penalties: Up to $15,000 per untrained operator.

8. What hidden costs should I budget for?

Shipping ($500–$5K)

Battery replacements ($400–$1.2K every 3–5 years)

Safety upgrades (e.g., fall arrest systems)

9. How can I get the best price?

Buy Direct (e.g., from manufacturers like JNHC LIFT)

Time Purchases for year-end sales

Negotiate free accessories (tool trays, extra batteries)

Conclusion: Smart Buying Guide for Electric Mobile Scissor Lift Tables (2025)

When investing in an electric mobile scissor lift table, remember that pricing depends on load capacity (500–5,000+ lbs), lift height (3–20+ ft), brand reputation (Genie vs. budget brands), and additional features like OSHA compliance or wireless controls. While upfront costs range from $1,500–$20,000+, the true value comes from balancing safety, durability, and long-term performance over short-term savings.

Key Takeaways:

✔ Entry-level lifts ($1.5K–$5K) work for light tasks but may lack longevity.

✔ Mid-range models ($5K–$12K) offer the best ROI for frequent industrial use.

✔ Premium lifts ($12K+) ensure reliability for heavy-duty applications.

✔ Hidden costs (shipping, maintenance, training) can add 15–30% to your budget.

Safety First: Cutting corners on quality risks operator safety and OSHA fines. Prioritize certified brands with robust warranties and compliance features.

Ready to Buy?

For the best combination of price and performance, request a customized quote from JNHC LIFT—a trusted direct manufacturer offering:

✅ Factory-direct pricing (20–40% lower than distributors)

✅ CE/ISO-certified electric scissor lifts

✅ Tailored solutions for your specific needs

Act Now!

Contact JNHC LIFT today for a free consultation and exclusive 2025 deals on high-quality lift tables.