Scissor lifts look simple at first glance—up, down, job done. But anyone who has ever maintained, repaired, or sourced one knows the truth: a scissor lift is a carefully coordinated system of mechanical, hydraulic, electrical, and safety components. Each part matters. When one fails, the whole machine complains loudly, usually at the worst possible time.

Understanding scissor lift parts is essential for operators, fleet managers, rental companies, and buyers who want reliability, safety, and long service life. This guide takes a deep dive into the core components of a scissor lift, explaining what each part does, why it matters, common failure points, and maintenance considerations.

What Are Scissor Lift Parts?

Scissor lift parts refer to all the individual components that work together to allow a scissor lift to raise, lower, steer, stop, and operate safely. These parts can be broadly divided into:

Structural components

Hydraulic system parts

Electrical and control components

Drive and mobility parts

Safety devices

A scissor lift is only as strong as its weakest bolt, hose, or sensor. Knowing the parts helps you troubleshoot faster, buy smarter, and maintain safer machines.

Main Structural Parts of a Scissor Lift

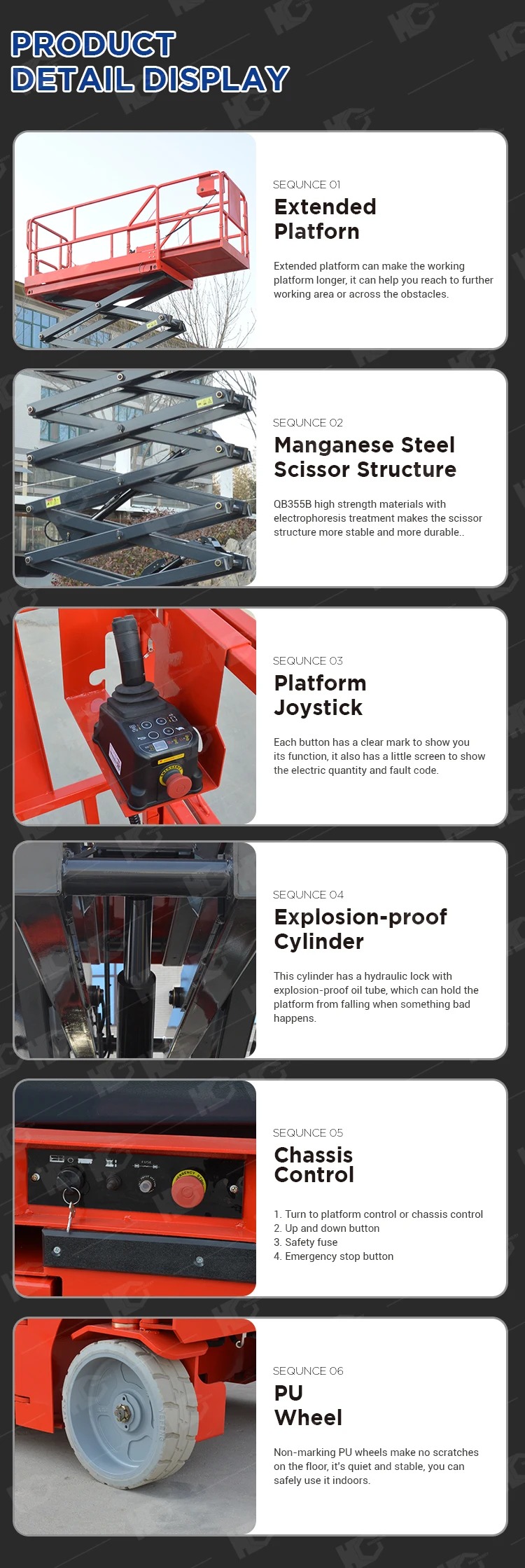

1. Scissor Arms (Pantograph Structure)

The scissor arms are the defining feature of the machine. Arranged in a crisscross (X-shaped) pattern, they expand and contract vertically to raise or lower the platform.

Key characteristics:

Made from high-strength steel

Designed to carry both vertical load and lateral forces

Connected by pivot pins and bushings

Common issues:

Worn pivot points

Bent arms due to overloading

Cracks caused by fatigue or corrosion

Regular inspection of welds and pivot areas is critical, especially on high-hour machines.

2. Base Frame (Chassis)

The base frame supports the entire scissor lift. It houses major components such as the hydraulic power unit, batteries or engine, and drive system.

Functions:

Provides structural stability

Supports wheel assemblies

Protects internal components

Damage to the base frame—often from impacts or uneven terrain—can affect alignment and lift stability.

3. Platform (Work Deck)

The platform is where people and tools stand. It may look like just a metal deck, but it plays a key role in safety and usability.

Typical features:

Anti-slip steel surface

Extendable platform sections

Toe boards and guardrails

Entry gates or chains

Platform extensions are technically separate scissor lift parts and often include rollers, locking pins, and guide rails.

Hydraulic System Parts

The hydraulic system is the muscle of a scissor lift. Without it, the lift stays politely on the ground.

4. Hydraulic Pump

The hydraulic pump generates the pressure needed to raise the scissor arms.

Types:

Electric motor-driven pumps (electric scissor lifts)

Engine-driven pumps (diesel or gasoline models)

Key considerations:

Flow rate affects lifting speed

Pressure rating determines lifting capacity

Pump failure often shows up as slow lifting, overheating, or strange noises.

5. Hydraulic Cylinders

Hydraulic cylinders convert hydraulic pressure into linear motion, extending and retracting to move the scissor arms.

Characteristics:

Single-acting or double-acting designs

Heavy-duty seals and rods

Precision-machined barrels

Common problems:

Oil leaks from worn seals

Bent rods from overloads

Internal leakage causing platform drift

Cylinders are among the most critical scissor lift parts for safety.

6. Hydraulic Hoses and Fittings

Hydraulic hoses carry pressurized oil between components.

Important points:

Rated for high pressure

Must resist abrasion and weather

Proper routing prevents chafing

A failed hose can instantly disable a lift—or worse. Preventive replacement is cheaper than emergency cleanup.

7. Control Valves

Control valves regulate oil flow and direction.

Types include:

Directional control valves

Flow control valves

Pressure relief valves

They ensure smooth lifting, controlled lowering, and overload protection.

Electrical and Control System Parts

Modern scissor lifts rely heavily on electronics. These parts are the brains of the operation.

8. Control Box (Platform & Ground Controls)

The control box allows operators to raise, lower, and drive the lift.

Includes:

Joysticks or switches

Emergency stop buttons

Indicator lights

Most scissor lifts have both platform controls and ground controls for safety and maintenance.

9. Control Module / PLC

The control module (sometimes a PLC) processes signals from sensors and operator inputs.

Functions:

Controls lift logic

Prevents unsafe operations

Manages fault codes

When this part fails, the lift may behave unpredictably—or not move at all.

10. Wiring Harness and Connectors

Wiring harnesses connect all electrical components.

Common issues:

Broken wires from vibration

Corrosion in connectors

Pinched cables during maintenance

Electrical problems often masquerade as hydraulic failures, so wiring should never be ignored.

11. Limit Switches and Sensors

Sensors ensure the lift operates within safe limits.

Typical sensors include:

Upper and lower limit switches

Tilt sensors

Load sensors

Pothole protection sensors

These small parts play an outsized role in preventing accidents.

Drive and Mobility Parts

Scissor lifts need to move, not just lift.

12. Drive Motors

Drive motors power the wheels on self-propelled scissor lifts.

Types:

Electric drive motors

Hydraulic drive motors

They determine travel speed, climbing ability, and maneuverability.

13. Gearboxes and Axles

Gearboxes transfer torque from motors to wheels, while axles support the load.

Wear points:

Gears under heavy load

Bearings exposed to dirt and moisture

Routine lubrication extends service life significantly.

14. Wheels and Tires

Wheels and tires vary by application:

Solid rubber tires (indoor)

Non-marking tires

Foam-filled tires (rough terrain)

Tire condition directly affects stability and traction.

Power System Parts

15. Batteries (Electric Scissor Lifts)

Electric scissor lifts typically use deep-cycle batteries.

Considerations:

Battery capacity affects runtime

Charging habits impact lifespan

Corrosion on terminals causes power loss

Battery maintenance is often neglected—and then blamed.

16. Charger

The battery charger ensures proper charging voltage and current.

Modern chargers are:

Automatic

Multi-stage

Designed to prevent overcharging

Using the wrong charger shortens battery life dramatically.

17. Engine (Diesel / Gas Scissor Lifts)

For engine-powered lifts, key parts include:

Engine block

Fuel system

Cooling system

Exhaust

These scissor lift parts follow standard engine maintenance rules but operate in dusty, high-load environments.

Safety-Related Scissor Lift Parts

Safety is not optional in lifting equipment.

18. Emergency Stop System

Emergency stop buttons instantly cut power to movement functions.

They must:

Be clearly labeled

Be easily accessible

Function reliably every time

19. Emergency Lowering System

In case of power failure, emergency lowering valves allow the platform to descend safely.

This is one of the most critical safety features—and often the least tested.

20. Guardrails and Gates

Guardrails, mid-rails, toe boards, and entry gates prevent falls.

Damaged or missing rails are a leading cause of scissor lift accidents.

21. Pothole Protection System

Many modern scissor lifts include automatic pothole protection bars that deploy at height to increase stability.

These systems rely on:

Mechanical linkages

Springs

Sensors

They must move freely to function correctly.

Wear Parts vs. Structural Parts

Not all scissor lift parts age the same way.

Wear parts include:

Seals

Hoses

Bushings

Filters

Tires

Structural parts include:

Scissor arms

Frames

Platforms

Understanding this distinction helps plan maintenance budgets realistically.

OEM vs. Aftermarket Scissor Lift Parts

When replacing parts, buyers often face a choice.

OEM parts:

Guaranteed compatibility

Higher cost

Manufacturer support

Aftermarket parts:

Lower cost

Varying quality

Suitable when sourced carefully

For safety-critical components, quality matters more than savings.

Maintenance Tips for Scissor Lift Parts

Good maintenance is boring—and incredibly effective.

Best practices:

Daily visual inspections

Regular lubrication

Scheduled hydraulic oil changes

Battery care and charging discipline

Immediate repair of leaks and faults

Ignoring small issues turns affordable parts into expensive downtime.

Common Scissor Lift Part Failures and Causes

Typical failure causes include:

Overloading the platform

Operating on uneven ground

Poor lubrication

Electrical moisture intrusion

Skipped inspections

Machines remember how you treat them.

How to Identify the Right Scissor Lift Parts

Before ordering parts, always confirm:

Lift brand and model

Serial number

Year of manufacture

Part number and revision

Guessing is faster—and more expensive.

Conclusion: Why Understanding Scissor Lift Parts Matters

A scissor lift is not just a platform on crossed arms. It is a system where hydraulics, electronics, mechanics, and safety devices cooperate under load, height, and pressure. Understanding scissor lift parts helps operators work safer, maintenance teams troubleshoot faster, and buyers make smarter decisions.

Whether you manage a rental fleet, maintain industrial equipment, or simply want fewer breakdowns on the job site, knowing the parts inside the machine turns surprise failures into planned maintenance—and that is always a good trade.

812.webp)