In many workplaces, the real challenge is not reaching extreme heights, but working safely, efficiently, and legally at low heights. Tasks between ground level and 4 meters are everywhere: installing lights, repairing ceilings, stocking shelves, maintaining HVAC outlets, or doing finish work inside buildings. Traditionally, these jobs rely on ladders or makeshift platforms, which are cheap—but also unstable, inefficient, and increasingly restricted by safety regulations.

This is where the 4 m mini mobile scissor lift quietly becomes one of the most cost-effective and practical access solutions on the market.

Compact, lightweight, easy to transport, and simple to operate, a 4-meter mini mobile scissor lift is designed specifically for short-reach vertical access, where full-size scissor lifts or boom lifts are unnecessary, overpowered, or impossible to deploy.

This article provides a complete buyer-level guide to the 4 m mini mobile scissor lift: what it is, how it works, where it is used, how it compares to ladders and scaffolding, and—most importantly—which buyer pain points it solves.

What Is a 4 m Mini Mobile Scissor Lift?

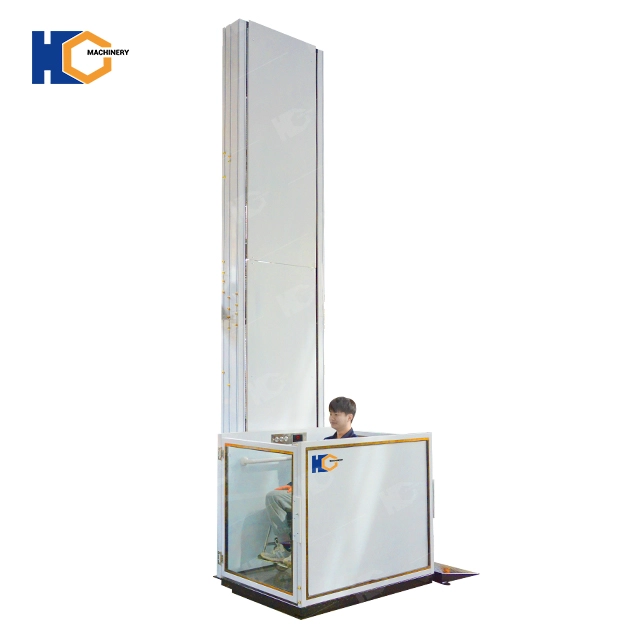

A 4 m mini mobile scissor lift is a compact vertical lifting platform that raises operators to a maximum working height of approximately 4 meters (around 13 feet). It uses a scissor-type mechanical structure powered by electric or hydraulic systems to lift a stable work platform straight upward.

Unlike large industrial scissor lifts, the “mini” version focuses on:

Low working height

Small footprint

Lightweight structure

Easy indoor maneuverability

Simple power systems (manual push or self-propelled)

Most models are designed for one or two operators, along with tools and light materials.

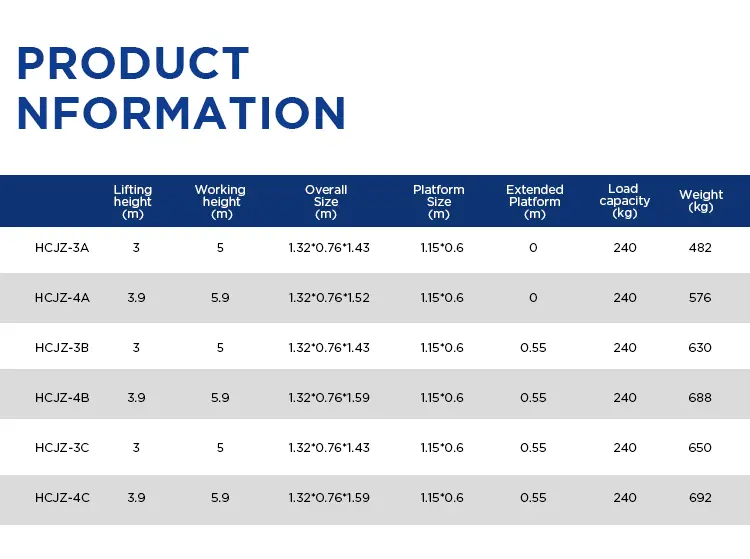

Typical Technical Overview (General)

While specifications vary by manufacturer, most 4 m mini mobile scissor lifts share common characteristics:

This design philosophy is not about power—it is about precision, safety, and convenience.

| Item | Specification |

|---|---|

| Product Type | Mini Mobile Scissor Lift |

| Max. Working Height | 4.0 m |

| Max. Platform Height | 2.0 m |

| Rated Load Capacity | 200 – 300 kg |

| Platform Dimensions (L × W) | 900 × 600 mm (customizable) |

| Overall Length | 1,200 – 1,400 mm |

| Overall Width | 700 – 760 mm |

| Overall Height (Lowered) | ≤ 1,650 mm |

| Lift Mechanism | Hydraulic scissor structure |

| Power Supply | Electric (DC battery) |

| Battery Type | Maintenance-free lead-acid or lithium (optional) |

| Battery Capacity | 24V / 60–80Ah |

| Charger | Intelligent automatic charger |

| Drive Type | Manual push / Self-propelled (optional) |

| Travel Speed (Lowered) | 3.0 – 4.0 km/h |

| Gradeability | 15 – 20% |

| Turning Radius | ≤ 1.5 m |

| Platform Control | On-platform control + ground control |

| Guardrail Height | ≥ 1,100 mm |

| Safety Features | Emergency stop, overload protection, safety valve |

| Tire Type | Non-marking solid rubber tires |

| Suitable Floor | Flat indoor & light outdoor surfaces |

| Noise Level | < 70 dB |

| Operating Temperature | -5°C to +45°C |

| Machine Weight | 450 – 650 kg |

| Compliance | CE / ISO (depending on configuration) |

Scissor Lift parts

Here’s the English version of the 4 m mini mobile scissor lift accessories guide:

1. Safety Accessories

| Accessory | Function & Description |

|---|---|

| Emergency Lowering Device | Allows the platform to safely descend manually or mechanically in case of power failure or malfunction |

| Extended Guardrails | Increases operator safety by preventing falls from the platform |

| Anti-Slip Platform Mat | Improves grip for personnel and tools on the platform |

| Warning Lights / Alarms | Alerts surrounding personnel that the lift is in operation, enhancing site safety |

| Harness Anchor Point | Provides attachment for safety harnesses, meeting fall protection requirements |

2. Operation & Control Accessories

| Accessory | Function & Description |

|---|---|

| Ground Control Panel | Allows lift operation from the ground, useful for moving or emergency control |

| Remote Controller / Handheld Controller | Provides flexible operation and remote control of lifting and movement |

| Platform Extension | Expands working space, accommodating more personnel or tools |

| Swivel / Directional Castors | Enhances mobility in small indoor spaces |

3. Power & Electrical Accessories

| Accessory | Function & Description |

|---|---|

| Spare Battery Pack | Extends working hours and ensures continuous operation |

| Battery Charger | Smart charging prolongs battery life and supports fast charging |

| Hydraulic Filter / Oil Tank | Maintains hydraulic system stability and extends service life |

| Electric Drive Kit | For self-propelled models, enables movement and slope climbing |

4. Additional Functional Accessories

| Accessory | Function & Description |

|---|---|

| Tool Tray / Holder | Stores tools or materials on the platform, reducing trips up and down |

| AC Power Outlet | Provides electricity for tools or devices while on the platform |

| LED Work Light | Improves visibility in low-light conditions |

| Canopy / Weather Cover | Provides shade or rain protection for outdoor use |

Summary

These accessories can significantly enhance a 4 m mini mobile scissor lift in terms of:

Safety: fall protection and emergency operation

Flexibility: remote control, mobility, platform extension

Efficiency: tool storage, on-platform power, long battery life

Versatility: suitable for indoor, confined spaces, and light outdoor use

Why the Market Needs 4 m Mini Scissor Lifts

From a buyer’s perspective, most access equipment on the market is overkill for everyday tasks.

A full-size scissor lift:

Costs more

Requires more storage space

Is heavier and harder to transport

Needs trained operators

May not fit through doors or elevators

A ladder:

Is cheap

But unsafe

Often illegal for certain jobs

Causes fatigue

Limits productivity

Creates liability risks

The 4 m mini mobile scissor lift exists in the sweet spot between these two extremes.

Buyer Pain Point #1: Ladder Safety and Compliance

The Problem

Many countries now restrict or discourage ladder use for repetitive or professional work. Insurance companies and safety inspectors increasingly flag ladder use as a high-risk behavior.

Common ladder issues include:

Falls due to imbalance

Overreaching

Slipping on smooth floors

Fatigue from prolonged standing

No guardrails or fall protection

The Solution

A 4 m mini mobile scissor lift offers:

Guardrails around the platform

Stable vertical lifting

Non-slip platform flooring

Emergency stop systems

Controlled ascent and descent

For buyers, this means reduced injury risk, fewer incidents, and easier safety compliance—which translates directly into lower insurance costs and fewer work stoppages.

Buyer Pain Point #2: Limited Indoor Space

The Problem

Many work environments are space-constrained:

Retail stores

Supermarkets

Hotels

Hospitals

Office buildings

Warehouses with narrow aisles

Standard scissor lifts are often too wide or too heavy to operate in these areas.

The Solution

Mini scissor lifts are designed with:

Narrow chassis

Tight turning radius

Low overall weight

Ability to pass through standard doors

Some models can even be moved inside elevators, making them ideal for multi-floor indoor maintenance.

Buyer Pain Point #3: Transport and Storage Difficulties

The Problem

Full-size access equipment requires:

Trucks or trailers

Loading ramps

Specialized transport permits

Large storage areas

For small contractors or facility teams, this becomes expensive and impractical.

The Solution

A 4 m mini mobile scissor lift:

Fits in small vans or pickups

Can be manually pushed into position

Requires minimal storage space

Can be used across multiple sites in one day

This dramatically reduces logistics costs, especially for service companies.

Buyer Pain Point #4: Overpaying for Height You Don’t Need

The Problem

Many buyers purchase or rent equipment rated for 8 m, 10 m, or more—only to use it at 3 m most of the time.

That means:

Paying more upfront

Higher maintenance costs

Higher energy consumption

More complicated controls

The Solution

A 4 m mini scissor lift is purpose-built for:

Ceiling work

Lighting installation

Cable routing

Fire alarm installation

CCTV setup

You pay for exactly the capability you use, not unnecessary height.

Common Applications of 4 m Mini Mobile Scissor Lifts

These lifts are widely used across industries where short-reach vertical access is routine.

Building Maintenance

Ceiling repairs

Painting

Electrical fixture replacement

HVAC vent inspection

Warehousing and Logistics

Shelf restocking

Inventory inspection

Light racking maintenance

Retail and Commercial Spaces

Store signage installation

Lighting upgrades

Decoration and seasonal displays

Hotels, Hospitals, and Offices

Corridor lighting

Fire detector maintenance

Cable and sensor installation

Manufacturing Facilities

Equipment inspection

Assembly line maintenance

Overhead piping checks

Manual Push vs Self-Propelled Mini Scissor Lifts

Manual Push Models

These are the most economical option.

Advantages:

Lower purchase price

Lighter weight

Simpler maintenance

Ideal for flat indoor floors

Best for:

Occasional use

Small teams

Tight budgets

Self-Propelled Models

These include electric drive motors.

Advantages:

Can move while elevated (on some models)

Faster repositioning

Less physical effort

Best for:

Frequent use

Larger facilities

Rental fleets

Electric Power: Quiet, Clean, Indoor-Friendly

Most 4 m mini scissor lifts use electric battery power, which brings several advantages:

Zero emissions

Low noise levels

Suitable for indoor environments

Lower operating cost than fuel engines

This makes them ideal for occupied buildings, such as offices, shopping malls, and hospitals, where noise and exhaust are unacceptable.

Stability and Load Capacity

Despite their small size, mini scissor lifts are engineered to maintain excellent stability.

Key design features include:

Wide base relative to height

Reinforced scissor arms

Load-sensing safety systems

Automatic leveling on flat surfaces

Typical load capacity supports:

One operator

Tools

Small materials

This ensures efficient work without repeated trips up and down.

Maintenance and Operating Costs

One reason buyers favor 4 m mini scissor lifts is low lifetime cost.

Compared to larger lifts:

Fewer hydraulic components

Smaller batteries

Less wear and tear

Easier inspections

Routine maintenance usually includes:

Battery checks

Hydraulic oil inspection

Safety switch testing

Wheel and brake inspection

For buyers managing multiple units, this simplicity is a major advantage.

Rental vs Purchase: Which Makes More Sense?

When Renting Makes Sense

Short-term projects

One-time tasks

Testing before buying

When Buying Makes Sense

Regular maintenance work

Multiple job sites

Long-term cost control

Because 4 m mini scissor lifts are relatively affordable, ownership often pays off quickly compared to repeated rentals.

Comparison: Mini Scissor Lift vs Ladder vs Scaffolding

Compared to Ladders

Safer

More productive

Less physical strain

Better compliance with safety rules

Compared to Scaffolding

Faster setup

More mobile

Requires less storage

Lower labor cost

For many buyers, the mini scissor lift replaces both ladders and small scaffolds.

Who Should Buy a 4 m Mini Mobile Scissor Lift?

This equipment is ideal for:

Facility management companies

Electrical contractors

Maintenance service providers

Retail chains

Hotels and property managers

Rental companies

Small construction teams

If your work frequently happens between 2–4 meters, this lift is almost purpose-built for you.

Key Buying Considerations

When choosing a model, buyers should focus on:

Actual working height (not just platform height)

Load capacity

Platform size

Doorway clearance

Battery type and runtime

Safety certifications

After-sales support

A slightly cheaper unit without reliable support can become expensive very quickly.

The Bigger Picture: Productivity and Risk Reduction

The real value of a 4 m mini mobile scissor lift is not just its price—it is the system-level improvement it brings to daily operations.

It:

Reduces accidents

Speeds up routine tasks

Improves worker comfort

Simplifies compliance

Enhances professional image

In other words, it turns “small jobs” into smooth, repeatable workflows.

Final Thoughts

The 4 m mini mobile scissor lift is not a flashy machine. It does not reach dramatic heights or dominate construction sites. Instead, it quietly solves one of the most common and underestimated problems in modern workplaces: safe, efficient access at low heights.

For buyers tired of ladders, cramped scaffolding, or oversized equipment, this compact lift represents a smart, practical upgrade—one that pays for itself through safety, efficiency, and peace of mind.

In the world of access equipment, sometimes smaller really is smarter.