Cargo lifts and freight elevators are essential material-handling systems designed to transport goods vertically, but they serve distinct purposes in different environments. A cargo lift is typically an open-platform or enclosed vertical lifting device used for moving materials in warehouses, construction sites, and loading docks. In contrast, a freight elevator is a heavy-duty, code-compliant elevator system, often enclosed, designed for moving large loads in commercial buildings, hospitals, and industrial facilities. While both systems improve efficiency and safety in goods transportation, their designs, capacities, and regulatory requirements differ significantly.

In industrial, warehouse, and commercial settings, these systems play a critical role in optimizing workflow, reducing manual labor, and ensuring safe material transport. Warehouses may prefer cargo lifts for their flexibility and cost-effectiveness, while hospitals and manufacturing plants often rely on freight elevators for their higher weight capacities and stringent safety compliance. Choosing the wrong system can lead to operational inefficiencies, increased costs, or even safety hazards—making it crucial to understand their differences.

So, which one is right for your needs? This article explores the key distinctions between cargo lifts and freight elevators, comparing their designs, load capacities, speed, regulations, and ideal applications. By the end, you’ll have a clear understanding of which solution best fits your operational requirements—whether you’re managing a small warehouse, a construction project, or a large commercial facility.

366846.webp)

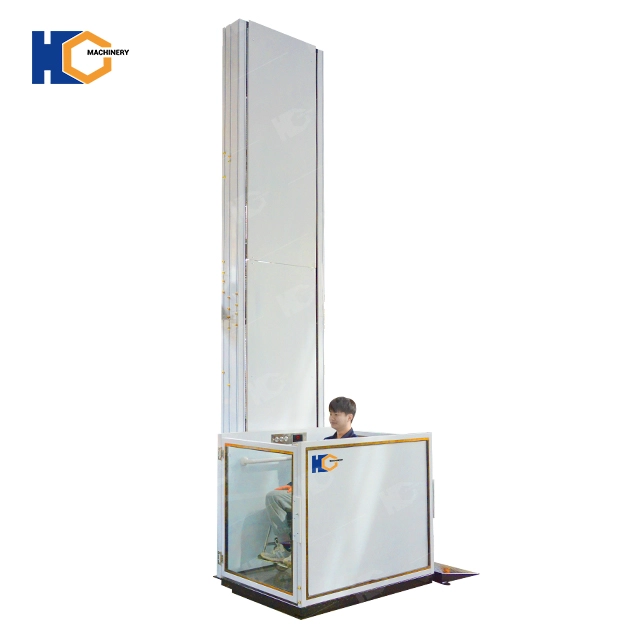

What Is a Cargo Lift?

A cargo lift (also called a goods lift or material lift) is a mechanized lifting system designed to transport heavy loads vertically between different levels of a facility. Unlike passenger elevators, cargo lifts are built for durability and efficiency in moving goods rather than people. Their primary function is to streamline material handling, reduce manual labor, and improve workplace safety in industrial and commercial environments. These lifts are commonly used in settings where frequent, heavy-load transportation is required, such as warehouses, factories, and construction sites.

Common Types of Cargo Lifts

Cargo lifts come in various designs, each suited for different operational needs:

Hydraulic Cargo Lifts – Powered by hydraulic pistons, these lifts provide smooth and reliable lifting for medium to heavy loads. They are ideal for low- to mid-rise applications and require minimal maintenance.

Electric (Traction) Cargo Lifts – Using electric motors and counterweights, these lifts are energy-efficient and well-suited for buildings with higher vertical travel needs.

Scissor Lifts – Featuring a crisscrossing metal support mechanism, scissor lifts offer a stable, elevated platform for loading and unloading goods at different heights. They are often used in warehouses and logistics centers.

Dumbwaiters – Smaller, compact lifts designed for transporting lighter loads (like food, documents, or small packages) in restaurants, hospitals, and office buildings.

Typical Load Capacity and Speed

Load Capacity: Cargo lifts generally support weights ranging from 500 kg (1,100 lbs) to 10,000 kg (22,000 lbs), depending on the model and design.

Speed: Most cargo lifts operate at 0.1 to 0.5 meters per second (20–100 ft/min), prioritizing stability over speed to ensure safe material transport.

Best Suited For

Cargo lifts are widely used in industries where efficient vertical movement of goods is essential, such as:

Warehouses & Distribution Centers – For palletized goods, machinery, and inventory movement.

Construction Sites – Transporting building materials, tools, and equipment between floors.

Loading Docks – Assisting in the transfer of goods from trucks to storage areas.

Manufacturing Plants – Moving raw materials and finished products between production levels.

Retail & Hospitality – Smaller dumbwaiters help transport supplies in hotels, restaurants, and retail stores.

Due to their versatility, cost-effectiveness, and adaptability, cargo lifts are a preferred choice for businesses looking to enhance operational efficiency without the high costs and regulatory requirements of freight elevators.

725333.webp)

What Is a Freight Elevator?

A freight elevator is a heavy-duty vertical transportation system specifically engineered to move large, bulky, or heavy loads between floors in commercial and industrial facilities. Unlike standard passenger elevators or cargo lifts, freight elevators are built with reinforced structures to handle extreme weights and frequent use while complying with strict safety regulations. They play a vital role in industries where efficient movement of goods, equipment, or even vehicles is critical to daily operations.

Regulatory Standards & Safety Compliance

Freight elevators must adhere to rigorous safety and construction standards, including:

ASME B20.1 (Safety Standard for Conveyors and Related Equipment)

ASME A17.1/CSA B44 (Elevator and Escalator Safety Code)

OSHA Regulations (Occupational Safety and Health Administration)

These standards ensure structural integrity, proper load capacity ratings, emergency braking systems, and other safety mechanisms to prevent accidents.

Key Features of Freight Elevators

Enclosed Cab Design – Most freight elevators feature fully enclosed cabs with heavy-duty doors to protect both goods and personnel during transport.

Higher Load Capacity – Built to carry significantly heavier weights than standard cargo lifts, often ranging from 2,300 kg (5,000 lbs) to over 45,000 kg (100,000 lbs).

Automated Controls & Advanced Safety Systems – Many modern freight elevators include programmable logic controllers (PLCs), overload sensors, and backup power systems for smooth, reliable operation.

Durable Construction – Reinforced steel frames, industrial-grade flooring, and impact-resistant interiors withstand rough handling of heavy machinery, pallets, and equipment.

Typical Load Capacity and Speed

Load Capacity: Freight elevators typically support 2,300 kg to 45,000+ kg (5,000–100,000+ lbs), with specialized models handling even greater weights.

Speed: They operate at 0.5 to 1.5 meters per second (100–300 ft/min), balancing efficiency with safety for heavy loads.

Best Suited For

Freight elevators are indispensable in environments requiring robust, high-capacity vertical transport, such as:

Commercial Buildings – Moving furniture, appliances, or retail inventory in high-rises.

Hospitals & Medical Facilities – Transporting medical equipment, stretchers, and bulk supplies between floors.

Manufacturing Plants – Handling raw materials, industrial machinery, and large product shipments.

Parking Garages & Automotive Facilities – Some heavy-duty models can carry vehicles for maintenance or storage.

Airports & Shipping Terminals – Facilitating logistics for cargo and baggage handling systems.

Due to their strength, reliability, and compliance with strict safety codes, freight elevators are the preferred choice for heavy industrial and commercial applications where both capacity and regulation adherence are non-negotiable.

Key Differences Between Cargo Lifts and Freight Elevators

When choosing between cargo lifts and freight elevators, understanding their differences in design, capacity, regulations, and cost is crucial. Below is a detailed comparison to help you select the right solution for your needs.

1. Design & Structure

| Feature | Cargo Lift | Freight Elevator |

|---|---|---|

| Enclosure | Often open platform or mesh cage | Fully enclosed cab with heavy-duty doors |

| Construction | Simpler, modular design | Reinforced steel structure |

| Access | Manual or basic gate systems | Automated doors with safety sensors |

| Aesthetics | Industrial, functional | Can be customized for commercial spaces |

Why It Matters:

Cargo lifts offer flexibility for loading irregularly shaped items.

Freight elevators provide better protection for sensitive goods.

2. Load Capacity

| Type | Cargo Lift | Freight Elevator |

|---|---|---|

| Standard Range | 500–10,000 kg (1,100–22,000 lbs) | 2,300–45,000+ kg (5,000–100,000+ lbs) |

| Typical Use | Boxes, pallets, machinery | Industrial equipment, vehicles, heavy machinery |

Key Insight:

Freight elevators handle 5–10× heavier loads, making them essential for industries like manufacturing or automotive.

3. Speed & Efficiency

| Metric | Cargo Lift | Freight Elevator |

|---|---|---|

| Speed | 0.1–0.5 m/s (20–100 ft/min) | 0.5–1.5 m/s (100–300 ft/min) |

| Trip Time | Slower, prioritizes stability | Faster for high-traffic settings |

Best For:

Cargo lifts: Low-frequency, stable transport (e.g., warehouses).

Freight elevators: Time-sensitive logistics (e.g., hospitals, airports).

4. Regulations & Safety Standards

| Requirement | Cargo Lift | Freight Elevator |

|---|---|---|

| Codes | Fewer regulations (varies by region) | Must comply with ASME A17.1, OSHA, and local codes |

| Inspections | Less frequent | Mandatory annual inspections |

| Safety Features | Basic overload protection | Emergency brakes, backup power, fire-rated materials |

Critical Note:

Freight elevators in public spaces often require passenger-rated safety features, increasing complexity.

5. Installation & Cost

| Factor | Cargo Lift | Freight Elevator |

|---|---|---|

| Installation | Faster (modular designs) | Longer (structural reinforcements needed) |

| Cost | $15,000–$50,000+ | $50,000–$200,000+ |

| Maintenance | Lower (simpler mechanics) | Higher (complex systems) |

Budget Consideration:

Cargo lifts are 3–5× more affordable upfront, but freight elevators offer long-term value for heavy-duty use.

Comparison Table Summary

| Feature | Cargo Lift | Freight Elevator | Winner For |

|---|---|---|---|

| Cost | Lower | Higher | Budget-conscious projects |

| Capacity | Lighter | Heavy-duty | Industrial-scale needs |

| Speed | Slower | Faster | High-throughput facilities |

| Regulations | Fewer | Strict | Public/commercial buildings |

| Flexibility | More adaptable | Fixed designs | Custom applications |

Final Recommendation

Choose a cargo lift if:

You need an economical solution for light-to-medium loads.

Your facility has minimal regulatory requirements.

Quick installation and adaptability are priorities.

Choose a freight elevator if:

You transport extremely heavy or sensitive goods.

Compliance with strict safety codes is mandatory.

Speed and durability are critical for operations.

By evaluating these differences, you can optimize safety, efficiency, and ROI for your material-handling needs.

Applications: When to Use Cargo Lifts vs. Freight Elevators

Choosing between cargo lifts and freight elevators depends on your industry, operational needs, and budget. Below is a detailed breakdown of their ideal applications to help you make the right decision.

When to Choose a Cargo Lift

Cargo lifts are versatile, cost-effective solutions best suited for:

1. Warehousing & Logistics

Loading/Unloading Goods: Efficiently move pallets, boxes, and inventory between floors.

Distribution Centers: Streamline order fulfillment with vertical material flow.

Cold Storage Facilities: Transport perishable goods without expensive elevator modifications.

Why? Cargo lifts offer open-platform designs for easy loading and require less regulatory oversight than freight elevators.

2. Construction & Job Sites

Material Transport: Move tools, concrete, steel beams, and other heavy materials to upper floors.

Temporary Installations: Modular designs allow quick setup and relocation as projects progress.

Why? They handle rugged conditions and irregularly shaped loads better than enclosed elevators.

3. Small Businesses & Retail

Restaurants & Hotels: Dumbwaiters efficiently deliver food, linens, or supplies between floors.

Retail Stores: Move stock from storage areas to sales floors without expensive infrastructure.

Why? Lower installation costs and minimal maintenance make them ideal for budget-conscious operations.

4. Manufacturing & Light Industry

Assembly Lines: Transport components between production levels.

Maintenance Shops: Lift heavy machinery parts for repairs.

Why? Cargo lifts provide flexible configurations for specialized workflows.

When to Choose a Freight Elevator

Freight elevators are heavy-duty systems designed for demanding environments:

1. Heavy Industrial Facilities

Manufacturing Plants: Move raw materials, industrial machinery, or large product batches.

Automotive Factories: Transport vehicle parts or even entire cars between floors.

Why? Their higher load capacities (up to 100,000+ lbs) and reinforced cabs handle extreme weights safely.

2. Multi-Story Commercial Buildings

Hospitals & Medical Centers: Transport heavy medical equipment, stretchers, and bulk supplies.

Hotels & Office Towers: Move furniture, appliances, or maintenance equipment discreetly.

Why? They meet strict building codes and blend into aesthetic spaces better than industrial lifts.

3. High-Security or Sensitive Environments

Pharmaceutical Labs: Securely transport regulated materials in enclosed, climate-controlled cabs.

Airports & Shipping Hubs: Handle oversized cargo like baggage containers or freight pallets.

Why? Freight elevators offer superior protection against damage, theft, or environmental exposure.

4. Public & High-Traffic Facilities

Parking Garages: Some models carry vehicles between levels.

Shopping Malls: Efficiently restock stores without disrupting shoppers.

Why? They comply with accessibility and safety laws required in public spaces.

Comparison Table: Best Use Cases

| Application | Cargo Lift | Freight Elevator |

|---|---|---|

| Warehouse Logistics | ✔️ Best | ❌ Overkill |

| Construction Sites | ✔️ Ideal | ❌ Too permanent |

| Small Businesses | ✔️ Affordable | ❌ Expensive |

| Heavy Manufacturing | ❌ Limited | ✔️ Necessary |

| Hospitals/Hotels | ❌ Unsuitable | ✔️ Required |

| High-Security Transport | ❌ Risky | ✔️ Secure |

Final Decision Guide

✔️ Choose a Cargo Lift If:

You need a budget-friendly, flexible solution.

Your loads are under 10,000 kg (22,000 lbs).

You operate in a private industrial or warehouse setting.

✔️ Choose a Freight Elevator If:

You move extremely heavy or sensitive goods.

Your facility must comply with strict safety codes.

You need passenger-rated safety or public access.

By matching the right system to your operational needs, you can maximize efficiency, safety, and cost-effectiveness.

Pros and Cons Summary: Cargo Lifts vs. Freight Elevators

Selecting between cargo lifts and freight elevators requires weighing their advantages and limitations. Below is a balanced comparison to guide your decision.

Cargo Lifts

✅ Pros:

Cost-Effective

Lower upfront costs (typically $15,000–$50,000)

Reduced installation expenses (modular designs)

Easy Installation & Flexibility

Minimal structural modifications needed

Portable options for temporary job sites

Versatile Applications

Adaptable for warehouses, construction, and small businesses

Open-platform designs accommodate bulky/irregular loads

Simpler Maintenance

Fewer mechanical components than freight elevators

No mandatory annual inspections (region-dependent)

❌ Cons:

Limited Capacity

Max load typically 10,000 kg (22,000 lbs)

Unsuitable for extremely heavy industrial loads

Slower Speeds

Operates at 0.1–0.5 m/s (20–100 ft/min)

Less efficient for high-frequency transport

Lighter Safety Regulations

May lack emergency brakes or backup power

Not rated for passenger use

Freight Elevators

✅ Pros:

High Load Capacity

Handles 45,000+ kg (100,000+ lbs)

Ideal for manufacturing plants and automotive facilities

Faster Transport

Speeds up to 1.5 m/s (300 ft/min)

Optimized for time-sensitive logistics (e.g., hospitals)

Enhanced Safety & Compliance

Meets ASME A17.1/OSHA standards

Features: fire-rated materials, emergency brakes, backup power

Passenger + Goods Transport

Enclosed cabs allow mixed use (where permitted)

Required in public/commercial buildings

❌ Cons:

Higher Costs

Purchase price: $50,000–$200,000+

Expensive modifications (e.g., reinforced shafts)

Complex Maintenance

Requires annual certified inspections

More mechanical parts = higher servicing costs

Stringent Regulations

Lengthy permitting process

Not ideal for temporary installations

Quick Comparison Table

| Factor | Cargo Lift | Freight Elevator |

|---|---|---|

| Cost | Low ($15K–$50K) | High ($50K–$200K+) |

| Installation | Fast & simple | Slow, requires construction |

| Capacity | Up to 10,000 kg | 45,000+ kg |

| Speed | 0.1–0.5 m/s | 0.5–1.5 m/s |

| Safety Features | Basic | Advanced (ASME/OSHA compliant) |

| Best For | Warehouses, small businesses | Heavy industry, hospitals |

Final Recommendation

Opt for a cargo lift if you prioritize affordability, flexibility, and moderate loads.

Invest in a freight elevator if you need heavy-duty capacity, speed, or public compliance.

By aligning these pros and cons with your operational needs, you can select the most efficient and cost-effective solution.

920096.webp)

How to Choose Between a Cargo Lift and Freight Elevator

Selecting the right vertical transport system for your facility requires careful evaluation of five key factors. This guide will help you determine whether a cargo lift or freight elevator best fits your operational and budgetary needs.

1. Budget Constraints

Cargo Lifts:

Lower upfront cost ($15,000–$50,000)

Installation savings: Modular designs require less structural work

Maintenance: Simpler mechanics reduce long-term costs

Freight Elevators:

Higher initial investment ($50,000–$200,000+)

Additional expenses: May require reinforced shafts and specialized wiring

Ongoing costs: Mandatory inspections and complex repairs

Decision Tip:

Choose a cargo lift if you need a cost-effective solution for light-to-medium duty use.

Invest in a freight elevator if you require heavy-duty performance and can justify the ROI.

2. Required Load Capacity

Cargo Lifts:

Typically handle 500–10,000 kg (1,100–22,000 lbs)

Ideal for: Pallets, machinery parts, construction materials

Freight Elevators:

Capacity ranges from 2,300–45,000+ kg (5,000–100,000+ lbs)

Necessary for: Industrial equipment, vehicles, bulk hospital supplies

Decision Tip:

Calculate your maximum expected load, then add a 25% safety margin.

Remember that consistently overloading equipment voids warranties and creates safety hazards.

3. Frequency of Use

For Occasional/Light Use:

Cargo lifts with hydraulic systems (fewer moving parts, less maintenance)

Electric traction models for <50 daily cycles

For Heavy/Continuous Use:

Freight elevators with industrial-grade components

Gearless traction systems for 100+ daily cycles

Decision Tip:

High-frequency operations demand durable brakes, backup power, and premium motors to prevent downtime.

4. Space and Installation Limitations

Cargo Lifts Win When:

You need temporary or portable solutions (construction sites)

Existing structures can't support heavy modifications

Clear height is limited (scissor lifts need no overhead machine room)

Freight Elevators Require:

Dedicated elevator shafts (often 2+ meters square)

Pit depth (0.5–1.5m) and overhead clearance

Structural reinforcements for high-rise buildings

Decision Tip:

Conduct a site survey to assess:

Ceiling heights

Floor load ratings

Power supply availability

5. Compliance with Safety Regulations

Cargo Lifts:

Fewer regulations (varies by region)

May not require annual certified inspections

Often exempt from passenger elevator codes

Freight Elevators Must Have:

ASME A17.1 certification (US/Canada)

CE marking (Europe)

Regular inspections (quarterly/annual)

Accessibility features if used in public spaces

Decision Tip:

Hospitals, schools, and commercial buildings always need code-compliant freight elevators.

Private warehouses may opt for cargo lifts with basic OSHA compliance.

Decision-Making Checklist

Answer these questions to identify your best option:

What's your budget?

Under $50K → Cargo lift

Over $50K → Freight elevator

What's your heaviest load?

<10,000 kg → Cargo lift

10,000 kg → Freight elevator

How often will it operate daily?

<50 cycles → Cargo lift

50 cycles → Freight elevator

Can your facility support installation?

Limited space → Cargo lift

Dedicated shaft → Freight elevator

What regulations apply?

Minimal codes → Cargo lift

Strict compliance → Freight elevator

Final Recommendation

For most industrial and warehouse applications, cargo lifts provide the best balance of cost and functionality. However, heavy manufacturing, hospitals, and commercial buildings will benefit from investing in freight elevators despite the higher price.

Pro Tip: Consult with a lift engineer to analyze your specific requirements—many suppliers offer free site assessments.

Conclusion: Choosing Between Cargo Lifts and Freight Elevators

Cargo lifts and freight elevators serve distinct purposes in material handling. Cargo lifts offer affordability and flexibility for light-to-medium loads (up to 10,000 kg), making them ideal for warehouses, construction sites, and small businesses. Freight elevators, with their heavy-duty capacity (up to 45,000+ kg) and strict compliance, are essential for industrial plants, hospitals, and commercial buildings.

Final Recommendation:

Opt for a cargo lift if you prioritize cost-efficiency and moderate loads.

Choose a freight elevator if you need high-capacity, code-compliant transport for demanding environments.

Need help deciding? Consult with a lift specialist to evaluate your facility’s requirements and ensure optimal performance and safety.

260.webp)