What Is a Mast Lift?

A Mast Lift (also called a Vertical Personnel Lift or Scissor Lift) is a type of aerial work platform designed for vertical elevation. Unlike boom lifts, mast lifts move straight up and down, making them ideal for stable, controlled lifting in confined spaces. They are commonly used in:

✔ Warehouses & logistics

✔ Construction & maintenance

✔ Indoor installations (e.g., lighting, HVAC)

✔ Retail & event setups

Mast lifts are categorized mainly by their mast structure:

Single Mast Lift (Rare, limited height & stability)

Double Mast Lift (Most common, balanced performance)

Four Mast Lift (Heavy-duty, ultra-stable for high reaches)

Double Mast Lift vs. Four Mast Lift: Key Differences

| Feature | Double Mast Lift | Four Mast Lift |

|---|---|---|

| Stability | Good for moderate heights | Superior, especially at max height |

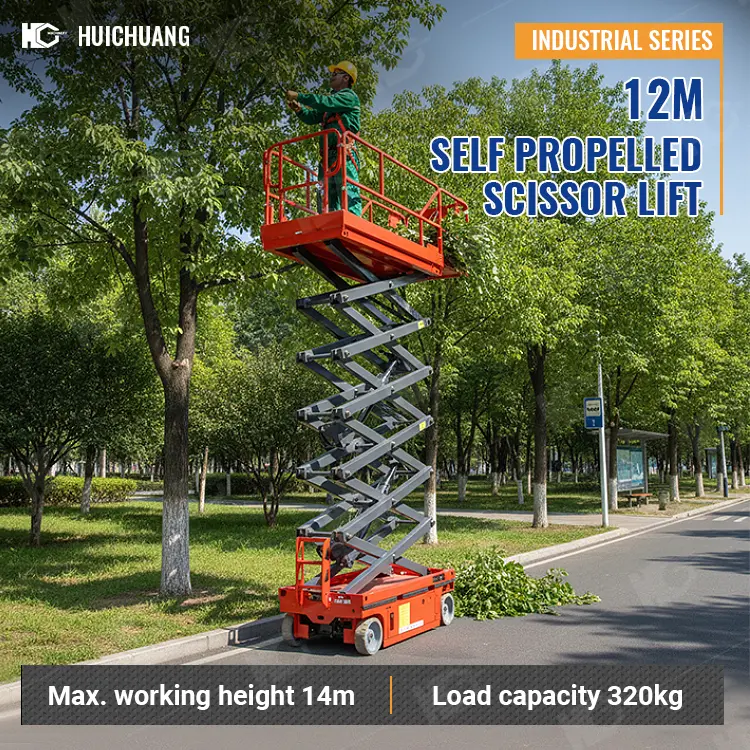

| Max Height | Typically 6-12m | 12-20m+ (some industrial models go higher) |

| Platform Size | Compact (1-2 workers) | Larger (2-3 workers + tools) |

| Load Capacity | 200-300kg | 300-500kg+ |

| Mobility | More maneuverable in tight spaces | Requires more space due to wider base |

| Cost | Lower (budget-friendly) | Higher (premium stability) |

| Power Options | Electric (indoor) / Diesel (outdoor) | Mostly heavy-duty electric or hybrid |

How to Distinguish Between High-Quality and Low-Quality Mast Lifts?

The quality of mast lifts (scissor lifts) directly impacts operational safety, equipment lifespan, and maintenance costs. Below are the key criteria for identifying high-quality and low-quality equipment to help you avoid pitfalls.

1. Structural Design and Materials

✅ High-Quality Features

✔ Heavy-Duty Steel: The main frame uses high-strength steel (e.g., Q345B) with precision welding (laser cutting + robotic welding).

✔ Stable Structure: Double or quadruple scissor design, wide chassis (anti-tip), minimal sway during lifting.

✔ Reinforced Protection: Critical stress points (e.g., cylinder mounts, platform connections) feature reinforcement.

❌ Low-Quality Features

✖ Thin Steel Plates: Cheap steel (prone to deformation), rough welding (visible pores, slag).

✖ Loose Structure: Noticeable platform wobbling during lifting, lightweight chassis (prone to tilting).

✖ No Anti-Rust Treatment: Lack of rust-proof primer, severe corrosion over time.

How to Check:

Tap metal parts—high-quality equipment sounds solid (thick), while low-quality sounds hollow (thin).

Inspect welds for uniformity and cracks.

2. Hydraulic and Electrical Systems

✅ High-Quality Features

✔ Imported Hydraulic Components: Cylinders and pumps from brands like Rexroth or Parker, leak-free with good sealing.

✔ Smart Control System: Overload protection, emergency descent, waterproof/dustproof circuitry (IP54+).

✔ Low-Noise Motors: Electric models operate below 70 dB (diesel models meet emission standards).

❌ Low-Quality Features

✖ Generic Hydraulics: Leaky cylinders, unstable pump pressure (jerky lifting).

✖ Poor Wiring: Exposed cables, no waterproofing (risk of short circuits in rain).

✖ High Noise/Emissions: Loud motors, visible black smoke from diesel models.

How to Check:

Observe hydraulic system stability during operation.

Inspect electrical enclosures for sealing and wire organization.

3. Safety Features

✅ High-Quality Features

✔ Multiple Safety Devices:

Fall arrest valve (slow descent if hose ruptures).

Tilt alarm (auto-lock if incline >3°).

Dual limit switches (prevents over-extension).

✔ Compliance: CE, ANSI/SAIA certified, clear safety labels.

❌ Low-Quality Features

✖ Missing Safety Devices: No fall arrest valve or non-functional.

✖ No Certifications: Fake CE marks, no test reports.

How to Check:

Request third-party certification (e.g., SGS test reports).

Test emergency stop button responsiveness.

4. Brand and After-Sales Service

✅ High-Quality Features

✔ Reputable Brands: E.g., JLG, Genie, Haulotte, Dingli (premium domestic).

✔ Reliable Support: 2+ years warranty, local service centers, prompt parts supply.

❌ Low-Quality Features

✖ Generic/White-Label: No official website or vague product info.

✖ Poor After-Sales: Short warranty (≤1 year), self-paid repairs for faults.

How to Check:

Research brand reputation and user reviews.

Ask for nearby repair case references.

5. Price and Cost-Effectiveness

High-Quality: Higher upfront cost but low failure rate, 10+ years lifespan.

Low-Quality: Cheap initially but frequent repairs, may fail in 2-3 years.

Recommendation:

For long-term use, choose high-quality (lower total cost).

For short-term projects, consider renting to avoid low-quality traps.

Summary: Quick Identification Tips

Check Steel: Thick, precise welds > thin, sloppy welds.

Test Operation: Smooth lifting > jerky/noisy.

Verify Safety: Functional fall arrest, certifications > missing protections.

Ask About Support: Reliable warranty > no-name brands.

Remember: Safety is paramount—never compromise quality for low prices! Always inspect equipment onsite or choose trusted suppliers.

How to Choose? Practical Recommendations

1. Choose a Double Mast Lift If:

✔ Working indoors (warehouses, factories, retail stores)

✔ Height needs ≤12m (e.g., ceiling repairs, shelf maintenance)

✔ Space is limited (narrow aisles, congested areas)

✔ Budget-conscious (lower upfront & maintenance costs)

Best for:

Light-duty maintenance

Frequent repositioning

Electric-powered environments

2. Choose a Four Mast Lift If:

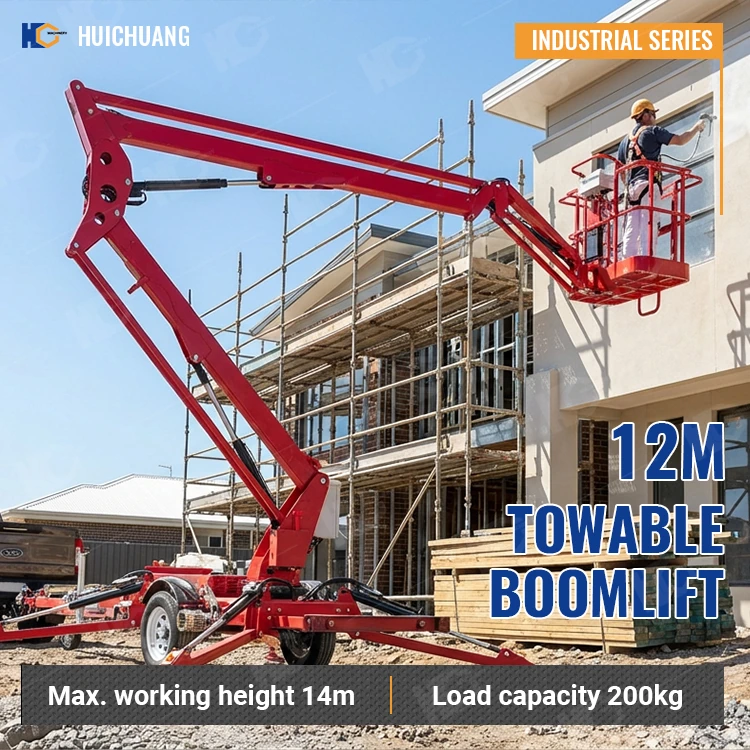

✔ Working at heights >12m (e.g., high-bay warehouses, industrial facilities)

✔ Heavy loads (multiple workers, bulky equipment)

✔ Outdoor/rough terrain (some models have rough-terrain capabilities)

✔ Maximum stability required (e.g., glass installation, precision work)

Best for:

Heavy industrial use

Long-duration elevated tasks

High-wind or unstable ground conditions

Final Tips for Selection

Test the Working Environment – Measure doorways, aisles, and ground conditions.

Check Power Needs – Electric for indoor/quiet ops; diesel/hybrid for outdoor.

Prioritize Safety – Four-mast lifts are safer at extreme heights.

Consider Rental vs. Purchase – Rent a four-mast for occasional high-reach jobs.

Top Models to Consider:

Double Mast: Genie GS-1930 (6m), JLG 1930ES (9m)

Four Mast: Snorkel S3215E (15m), Haulotte HA20 (20m)

Conclusion: Match the mast type to your height, load, and environment needs. For most indoor tasks under 12m, a double mast suffices. For heavy-duty or high-reach applications, invest in a four-mast lift. Always consult a supplier for site-specific advice!