In the bustling world of logistics, warehousing, and industrial operations, the dock leveler stands silently—but powerfully—at the gateway between the warehouse and the trailer. It’s often overlooked, taken for granted even, but its impact is immense. Have you ever paused to wonder: how does a dock leveler actually work? What unseen mechanics and technology allow it to perform its seemingly simple, yet utterly crucial, function?

Welcome to this in-depth journey where we’ll peel back the layers—both literally and conceptually—of dock levelers. And along the way, we’ll tie in the standards of excellence set by Jinan Huichuang Machinery Manufacturing Co., Ltd. (Huichuang Lift), a rising global name in lifting and access platform solutions.

Understanding the Purpose: What Is a Dock Leveler?

Let’s start from the top. A dock leveler is a device installed at loading dock doors to bridge the height difference between the dock and a truck trailer. Without it, forklifts and hand trucks would struggle—or fail entirely—to safely and efficiently move goods between warehouse and transport.

Types of Dock Levelers typically fall into three categories:

| Type | Mechanism | Common Use Case |

|---|---|---|

| Hydraulic Dock Leveler | Operated via hydraulic cylinders and electric pumps | Heavy-duty and high-frequency loading |

| Mechanical Dock Leveler | Spring-loaded, manually operated | Medium-load, cost-sensitive facilities |

| Air-Powered Dock Leveler | Inflatable air bag system | Clean environments like food or pharma |

The Core Question: How Does a Dock Leveler Work?

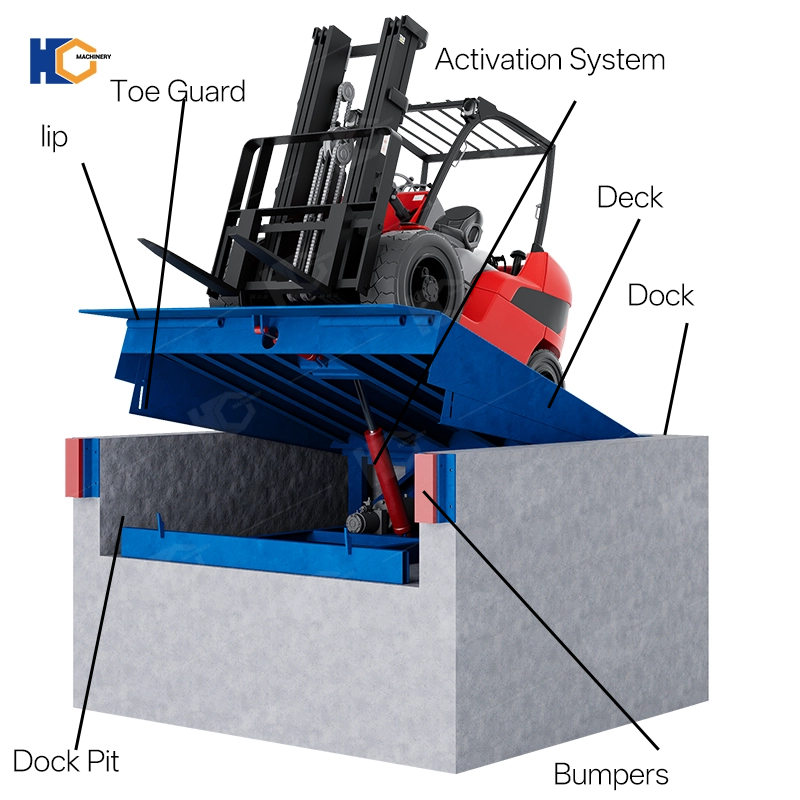

Let’s zero in. Whether hydraulic or mechanical, the core function of a dock leveler is to adjust its platform (called the deck) so that it aligns perfectly with the height of the truck bed.

1. Mechanical Dock Leveler Operation

It begins with a pull chain. Yes—manual labor is still involved. When an operator pulls the chain:

A release mechanism lifts the platform via a counterbalance spring system.

The lip (a hinged extension at the front) flips outward.

The platform slowly descends onto the trailer bed.

This system works well in low-cycle environments. However, it’s prone to wear and tear and demands regular manual effort and fine-tuning.

2. Hydraulic Dock Leveler Operation

This is where modern engineering kicks in. A push-button control system activates:

Hydraulic cylinders that lift the platform.

A separate cylinder extends the lip.

The platform is lowered onto the trailer, completing the bridge.

Simple? Perhaps. But the safety mechanisms, fluid dynamics, and electrical coordination make this a quiet marvel of industrial design.

Huichuang Hydraulic Dock Leveler

The Hidden Engineering: Inside the Mechanism

Let’s look under the deck—literally.

| Component | Function |

|---|---|

| Deck Plate | Main platform—must be anti-slip and rated for heavy loads |

| Lip Plate | Extends to bridge the dock and truck gap |

| Hydraulic Pump | Powers the cylinders in hydraulic systems |

| Cylinder Assembly | Controls platform lift and lip extension |

| Safety Legs | Prevents platform from collapsing during maintenance |

| Control Panel | Human-machine interface (HMI) for operating the leveler |

The synergy between these parts determines the efficiency, safety, and lifespan of the dock leveler.

The Science of Slope: Why Angle Matters

Here’s where physics enters the room.

An average dock height is about 48 inches (1.2 meters), but trailer beds can range from 40 to 56 inches. The dock leveler compensates for this by adjusting the platform angle—typically between 12° to 15°. If the incline becomes too steep:

It compromises forklift stability.

Increases wear on forklift brakes and tires.

Endangers goods and personnel.

So yes, even a few degrees of tilt can significantly impact the operation.

Huichuang's Hydraulic Dock Leveler can provide products with different specifications and slopes according to your usage.

Real-World Statistics: The Cost of Downtime

According to a 2023 report by MHI (Material Handling Institute):

On average, 1 hour of downtime at a loading dock costs $300–$500 in labor and delivery delays.

Facilities with automated hydraulic levelers reported 28% fewer accidents than those using manual systems.

| Factor | Manual System | Hydraulic System |

|---|---|---|

| Avg. Downtime per Year | 45 hours | 22 hours |

| Maintenance Cost per Year | $1,000 | $400 |

| Employee Injury Risk Index | Moderate to High | Low |

Efficiency isn’t a luxury; it’s a necessity. This is where professional-grade products like those from Huichuang Lift shine.

Huichuang Lift: Elevating the Standard in Dock Leveling

Located in Jinan, Shandong, often called the “Hometown of Hydraulic Lifting Platforms,” Huichuang Lift is not just another manufacturer. With over 200 staff, independent R&D, and global market presence, they’re building a new benchmark in lifting solutions.

Why choose Huichuang Lift for dock levelers or custom platform solutions?

Certified Excellence: CE, ISO, ASME A17.1—meeting and exceeding international standards.

Tailored Solutions: From warehouses to cleanrooms, solutions are engineered, not just assembled.

Durable Build: Anti-slip platforms, heavy-duty hydraulics, and intelligent control panels.

OEM and Custom Orders: Designed to suit your facility layout and load profile.

After-Sales Reliability: Responsive support, global agent network, and real maintenance backing.

As they say internally—“Don’t lift what you can elevate smarter.”

Huichuang's Hydraulic Dock Leveler can be customized according to your usage.

Safety First: What Makes a Dock Leveler Safe?

You might be thinking, “It’s just a metal bridge. What’s the risk?”

Well, consider this:

A single forklift accident due to a failed leveler can cost over $10,000 in damages, not counting potential lawsuits.

Improperly rated levelers can collapse under overweight loads, especially if misused.

Key Safety Features to Look For:

| Feature | Benefit |

|---|---|

| Emergency Stop Button | Instant halt in case of malfunction |

| Toe Guards | Prevent foot injury during operations |

| Safety Maintenance Strut | Locks the platform in raised position for safe servicing |

| Overload Protection | Prevents lift if load exceeds capacity |

At Huichuang Lift, these features are standard—not premium add-ons.

Installation and Maintenance: Not Just Plug and Play

Installation involves:

Mounting into a concrete pit or edge-of-dock bracket

Electrical connections to local control systems

Safety inspection and user training

Routine Maintenance Includes:

Checking hydraulic fluid levels

Inspecting wear on the lip hinge

Recalibrating safety sensors

Lubricating moving parts

Pro tip: Facilities that conduct monthly checks report 25% longer dock leveler lifespan.

Final Thoughts: The Quiet Hero of Material Handling

A dock leveler may not boast the glamour of an automated robot arm or a towering forklift, but without it, the entire flow of goods slows, stutters, or stops. It’s the quiet hero—reliable, rugged, and indispensable.

And if you're considering upgrading your warehouse or dock facility with cutting-edge technology, why not work with a brand like Huichuang Lift, whose mission is to make lifting smarter, safer, and more accessible for everyone?