When contractors, rental companies, or facility managers search for “14m self propelled electric scissor lift hydraulic system”, their intent is often very practical: they want to understand what this equipment is, how the hydraulic system works, whether an electric self-propelled scissor lift is suitable for their projects, and of course, what the cost, benefits, and specifications look like.

What is a Self Propelled Electric Scissor Lift?

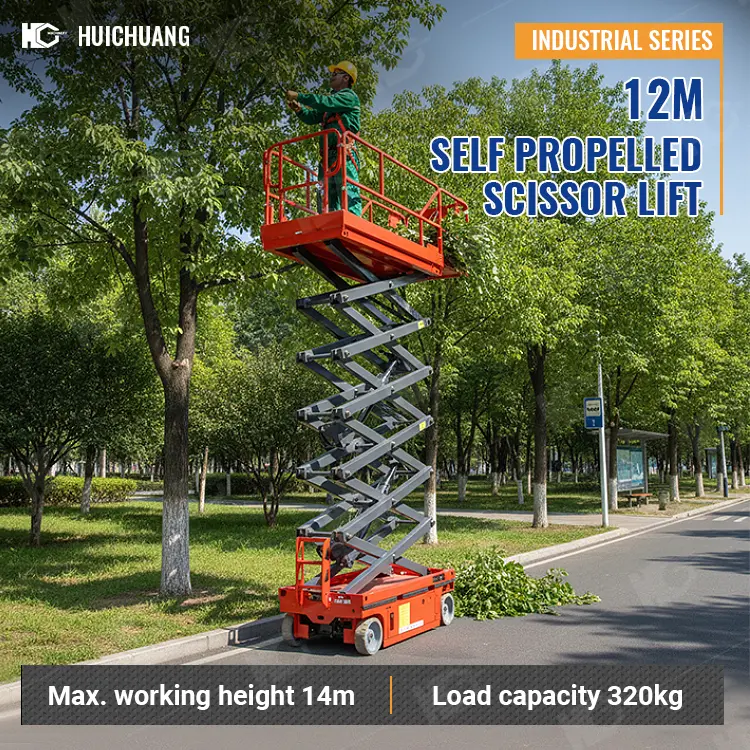

A self propelled electric scissor lift is an aerial work platform designed to raise workers and tools vertically to perform maintenance, installation, or construction tasks at height.

Self-propelled means the machine can move forward and backward under its own power without being towed.

Electric refers to the use of rechargeable batteries, making it eco-friendly, quiet, and suitable for indoor and outdoor use.

Scissor lift describes the lifting mechanism – a set of crisscrossing hydraulic arms (like a pair of scissors) that expand and contract to raise and lower the platform.

A 14m scissor lift typically provides a working height of 14 meters (46 feet), which is ideal for indoor warehouse racking, shopping mall maintenance, airport service, or light construction projects.

Why 14m Height Matters

When buyers search specifically for 14m self propelled electric scissor lifts, they are usually aiming for:

Medium-high projects: Above 12m, but not as tall as 20–30m boom lifts.

Cost-effectiveness: 14m offers the right balance between working height and affordability.

Compact design: Machines at this range still fit into freight elevators and can maneuver indoors.

Hydraulic System in a 14m Scissor Lift

The hydraulic system is the core technology that makes lifting smooth, stable, and safe.

Key Components:

Hydraulic Pump – Powered by the electric motor, it generates hydraulic pressure.

Cylinders – Extend and retract to push the scissor arms.

Scissor Arms – Cross-structured arms that expand upward.

Valves & Hoses – Regulate fluid flow and prevent sudden drops.

Hydraulic Oil – Transfers force through pressurized movement.

How it Works:

Operator presses the lift button → electric motor activates hydraulic pump → pressurized oil flows into cylinders → scissor arms extend → platform rises.

For descent, valves release hydraulic fluid gradually, lowering the platform safely.

Benefits of Hydraulic System in 14m Models:

Smooth vertical lifting even at maximum load (230–450 kg).

Safety features like emergency lowering in case of power failure.

Long service life with minimal maintenance if oil and seals are checked regularly.

Advantages of a 14m Self Propelled Electric Scissor Lift

Eco-Friendly Operation

Zero emissions, suitable for indoor spaces like airports, malls, and factories.

Low noise, ideal for noise-sensitive environments.

Mobility and Productivity

Self-propelled drive allows operators to reposition without leaving the platform.

25%–40% gradeability makes it usable on slight slopes.

Safety

Guardrails, anti-slip platform, overload sensors, tilt protection, and emergency stop buttons.

Cost Savings

Lower fuel costs compared to diesel lifts.

Less maintenance compared to combustion engines.

Versatility

Can be used both indoors and outdoors on firm, level surfaces.

Technical Specifications (Typical 14m Model)

Platform Height: 12m (working height ~14m)

Load Capacity: 320–450 kg

Platform Size: 2.3m x 1.15m (extendable deck optional)

Power Source: 24V/48V battery pack

Drive System: 2WD or 4WD depending on model

Travel Speed: 3–5 km/h

Gradeability: 25% (standard)

Hydraulic System: Dual cylinder with safety valves

Common Applications

Construction sites – interior finishing, ceiling installation, HVAC, and electrical wiring.

Facility management – warehouse inventory, lighting repair, signage maintenance.

Retail & malls – decoration, maintenance, or seasonal setup.

Airports & stations – indoor cleaning and maintenance of high ceilings.

Event venues – stage setup, lighting, and sound installation.

Cost of a 14m Self Propelled Electric Scissor Lift

Prices vary depending on brand, configuration, and country of purchase.

FOB China Factory Price: USD 15,000–22,000 (SGD 20,000–30,000)

European/US Market Price: USD 22,000–30,000

Rental Rate: Around USD 80–120 per day depending on location

When buyers search with keywords like cost or price, their intent is to compare direct purchase vs. rental. For long-term usage, buying from a China factory can save up to 30–40% compared to Western brands.

Buying Considerations

When selecting a 14m self propelled electric scissor lift, check:

Certifications: CE, ANSI, ISO9001 compliance.

Battery type: Maintenance-free gel or lithium battery options.

After-sales service: Availability of spare parts and local dealer support.

OEM options: Custom paint, branding, and platform design.

Warranty: Usually 12 months or 1,000 working hours.

Maintenance of Hydraulic System

Since many searchers also care about hydraulic system reliability, here are maintenance tips:

Check hydraulic oil every 500 hours; replace annually.

Inspect seals and hoses for leaks.

Bleed the system if air enters the hydraulic lines.

Keep filters clean to avoid contamination.

Test emergency lowering valve regularly.

Future Trends in 14m Electric Scissor Lifts

Lithium-ion batteries: Longer life, faster charging.

Telematics: Remote monitoring of hydraulic pressure, battery status, and machine health.

Compact design: Narrow chassis to fit tighter indoor spaces.

Improved hydraulic efficiency: Lower energy consumption and smoother operation.

Conclusion

The 14m self propelled electric scissor lift with hydraulic system is a powerful, safe, and eco-friendly solution for medium-height work. Buyers searching this term are typically looking for:

Technical understanding of hydraulic systems

Cost and application insights

Comparison of advantages vs. diesel lifts

Maintenance guidance

By considering specifications, costs, and maintenance practices, companies can select the right model that ensures safety, efficiency, and long-term value.

For contractors, rental companies, and facility managers, investing in a 14m electric scissor lift can boost productivity, reduce costs, and meet strict environmental regulations.

FAQ

1. What is the maximum working height of a 14m self propelled scissor lift?

The platform height is usually 12m, allowing a working height of 14m (46 ft).

2. How does the hydraulic system work in a scissor lift?

The electric motor powers the hydraulic pump, which drives oil into cylinders, extending the scissor arms and raising the platform smoothly.

3. What is the load capacity of a 14m model?

Most 14m electric scissor lifts support 320–450 kg, suitable for 2–3 workers plus tools.

4. Is it suitable for both indoor and outdoor use?

Yes. The electric drive is quiet and emission-free for indoor use, while the hydraulic system ensures stability outdoors on flat surfaces.

5. How long can the battery last on a single charge?

Depending on usage, the battery can last 6–8 hours of continuous work or a full workday with proper charging.

6. What safety features are included?

Standard features include emergency lowering, tilt sensors, overload protection, guardrails, and non-slip platform flooring.

7. What certifications should I check before purchase?

Look for CE, ANSI, or ISO9001 certifications to ensure compliance with international safety standards.

8. How much does a 14m self propelled electric scissor lift cost?

Factory prices from China range between USD 15,000–22,000, depending on configuration.

9. What maintenance is required for the hydraulic system?

Check hydraulic oil annually, inspect hoses for leaks, and test the emergency lowering valve regularly.

10. Can the lift be customized?

Yes. Options include platform size, battery type, paint color, OEM branding, and control panel language.