I. What is a Fully Self-Propelled Scissor Lift Platform?

A fully self-propelled scissor lift platform is a type of aerial work equipment that integrates autonomous mobility, intelligent control, and high stability. Its core feature is the ability to operate without external traction or manual assistance, leveraging an onboard power system (electric or diesel) to drive the chassis for movement, while hydraulic scissor mechanisms enable vertical lifting of the platform. It independently completes the full workflow of "mobility + elevation," emphasizing "full autonomy" in operations. Compared to semi-self-propelled models (which require manual pushing or external towing), it excels in "full self-sufficiency," making it ideal for complex terrains, narrow spaces, or high-altitude tasks requiring frequent repositioning.

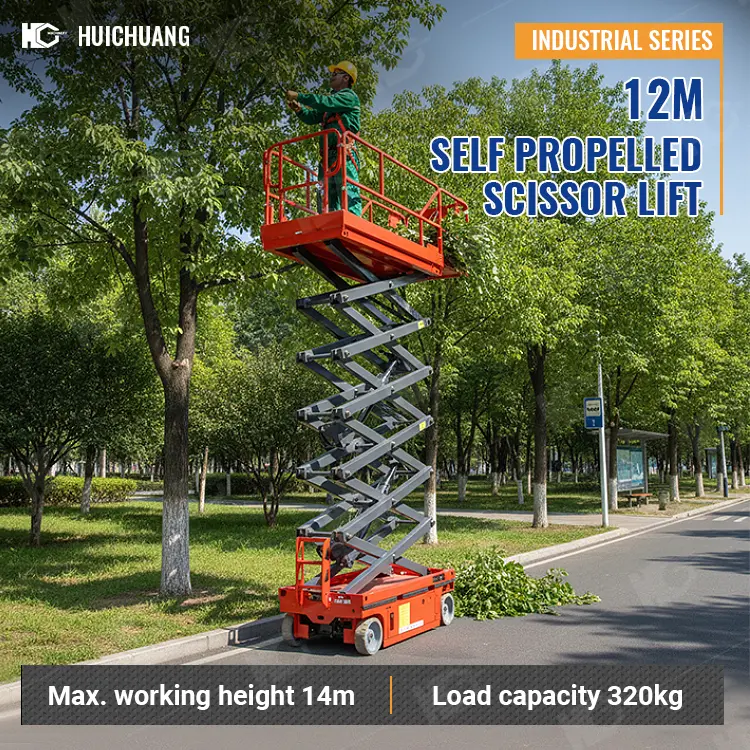

II. Technical Specifications of a 10m Fully Self-Propelled Scissor Lift Platform (Typical Parameters)

Below are reference specifications for mainstream 10m-class products (specific details may vary by manufacturer customization):

| Item | Parameter |

|---|---|

| Maximum working height | 10m (platform height above ground when scissor arms are fully extended) |

| Platform dimensions | Standard 1.5m×0.8m (customizable for wider/longer platforms upon request) |

| Maximum platform load | 230kg–500kg (230kg for standard models; up to 500kg for industrial-reinforced models) |

| Power system | Electric (48V/80V DC motor + lithium battery) or diesel (1.5L–3L displacement, meeting Euro V/China IV emissions standards) |

| Travel speed (loaded/unloaded) | 0–4km/h (electric); 0–5km/h (diesel) |

| Gradeability | ≤15° (electric); ≤25° (diesel) |

| Tire type | High-elastic polyurethane wheels (indoor/outdoor use) or pneumatic rubber wheels (for rough outdoor terrain) |

| Control method | Dual control via handheld remote + platform operation panel (supports forward/reverse, steering, lifting, and emergency stop) |

| Safety features | Anti-tipover sensor, overload alarm, emergency stop button, automatic braking, and optional spirit level |

| Operating temperature range | -20°C to +50°C (low-temperature models extendable to -30°C) |

| Charging time/fuel tank capacity | Electric: 8–10 hours to full charge (lithium battery with ≥800 cycle life); Diesel: 60L tank (8–12 hours of operation) |

III. Key Application Scenarios for 10m Fully Self-Propelled Scissor Lift Platforms

A 10m working height covers most medium-to-low altitude needs, with typical applications including:

Commercial space maintenance: Ceiling inspections, LED screen installation/cleaning, and air conditioning unit maintenance (no scaffolding required).

Industrial settings: Equipment installation in factories (e.g., production line debugging, pipeline maintenance) and high-level shelf access in warehouses.

Public facility operations: Dome cleaning in stadiums, lighting maintenance in school auditoriums, and municipal streetlight repairs (suitable for narrow streets).

Construction and decoration: Wall painting, glass curtain wall installation (electric models ideal for noise-sensitive indoor environments).

Emergency rescue: Assisting in transferring trapped individuals at low heights during fire or rescue operations (used alongside other equipment).

IV. Fully Self-Propelled vs. Semi-Self-Propelled Scissor Lift Platforms: Core Differences

| Comparison Dimension | Fully Self-Propelled Scissor Lift | Semi-Self-Propelled Scissor Lift |

|---|---|---|

| Mobility method | Onboard power system (electric/diesel) enables autonomous movement without external traction. | No onboard power; relies on manual pushing or external forklift towing. |

| Applicable scenarios | Complex terrains (slopes, gravel roads), frequent repositioning (≥5 moves/day), and narrow spaces. | Fixed sites (e.g., factory floors, construction sites) and low-frequency repositioning (≤2 moves/day). |

| Operational complexity | Intelligent controls (joystick/remote) support 360° turning and in-place maneuvering. | Manual direction control; large turning radius and low mobility flexibility. |

| Cost investment | Higher initial purchase cost (20%–30% more), but long-term labor cost savings. | Lower upfront cost; suitable for budget-constrained, low-mobility scenarios. |

| Power dependency | Electric models require charging infrastructure; diesel models need regular fuel system maintenance. | No additional power needs; minimal maintenance. |

V. 10 Key Considerations for Batch Procurement of Fully Self-Propelled Scissor Lift Platforms

Batch procurement requires balancing operational needs, cost, after-sales support, and long-term reliability. Below are critical considerations:

Clear requirement matching: Select models based on target working height (10m with potential extension needs), load capacity (230kg/500kg), and platform size (customization for wider/longer platforms if needed).

Power type selection: Prioritize electric models for indoor use (noise-free, zero emissions); choose diesel models for outdoor/unpowered sites.

Compliance verification: Ensure products meet national standards (e.g., GB 25849-2010 Scissor Lift Platforms) or industry certifications (CE, ANSI) to avoid regulatory risks.

Safety feature check: Mandatory features include anti-tipover protection, overload alarms, and emergency stop buttons; optional features like spirit levels enhance stability on uneven terrain.

Serviceability assessment: Verify that wear parts (hydraulic hoses, batteries) are standardized and that manufacturers offer nationwide warranties and rapid spare-part delivery.

Operator training support: Require manufacturers to provide free training (theoretical + practical) covering critical skills like emergency stops, steering, and platform leveling.

Delivery timeline and logistics: Confirm production lead times (typically 4–8 weeks) and clarify logistics responsibilities (delivered to site vs. self-pickup) and unloading conditions (forklift required).

Expandability design: Look for pre-installed interfaces (tool attachment points, power outlets) to support future add-ons (e.g., guardrails, material baskets) for improved efficiency.

Contract term clarification: Define warranty periods (1–2 years standard; 3 years recommended for core components like hydraulic pumps and motors) and fault response times (24-hour on-site service).

Bulk discount negotiation: Secure price concessions based on purchase volume (e.g., ≥10 units) and negotiate free trial periods (1–2 weeks) to mitigate procurement risks.

VI. FAQs

Q1: Can fully self-propelled platforms truly operate "autonomously"? Do they require manual assistance?

A: Yes, their onboard power systems and intelligent controls enable independent movement and steering without manual pushing. Manual assistance is only needed in extreme terrains (e.g., stairs), while routine tasks are self-sufficient.

Q2: Does the 10m working height refer to the total height when the platform is fully raised?

A: Yes. Working height = platform height above ground. A 10m platform allows workers to reach 10m-high points (e.g., ceilings, lights).

Q3: How to choose between electric and diesel models? Which is better for indoor use?

A: Indoor applications prioritize electric models (noise <65dB, zero emissions) to comply with environmental regulations in malls, offices, etc. Diesel models suit outdoor/unpowered sites.

Q4: Does the 230kg load capacity refer to two people or cargo?

A: 230kg is the total load limit. It can support two adults (~75kg each) + light tools, or one adult + 50kg of cargo. Avoid overloading to prevent activation of alarms.

Q5: Will the platform tip over on slopes? Does it have anti-slip design?

A: Reputable models are equipped with anti-tipover sensors (automatic shutdown at tilt angles >5°) and skid-resistant chassis patterns. For safety, operate on slopes ≤15° (electric models).

Q6: Do operators need certification? How long does it take for beginners to master operation?

A: No mandatory certification exists in China (though some enterprises require internal training). Beginners can gain proficiency in 1–2 hours of training (familiarization with joystick functions and emergency stops).

Q7: How long does the battery last? Does cold weather reduce performance?

A: Electric models with 80V/60Ah lithium batteries provide 6–8 hours of runtime under full load. Cold weather (<-10°C) reduces battery life by ~20%; preheat batteries before winter use.

Q8: Can the platform move while elevated? How stable is it?

A: Yes, but at reduced speeds (<1km/h). Scissor structures and dual hydraulic locks ensure stability; maximum wind resistance is 6 (13.8m/s).

Q9: Can manufacturers customize platforms during batch procurement (e.g., wider platforms or extended height)?

A: Most manufacturers support customization (e.g., platform width from 0.8m to 1.2m, height from 10m to 12m), but lead times extend by 2–3 weeks for custom orders.

Q10: Which faults are covered under warranty during the guarantee period? Are human-induced damages chargeable?

A: Warranties typically cover core components (hydraulic systems, motors, control systems). Human-induced damage (e.g., operator error causing scissor deformation, battery over-discharge) incurs service fees.

Conclusion: The 10m fully self-propelled scissor lift platform, with its "autonomous mobility + intelligent control" advantages, is the optimal choice for medium-to-low altitude tasks requiring frequent repositioning. Batch procurement should prioritize demand alignment, safety features, and after-sales support, selecting compliant, service-network-strong brands to maximize equipment value and operational efficiency.

After-Sales Service

Huichuang Lift, as a leading manufacturer of aerial work platforms, is committed to ensuring long-term reliability, safety, and operational efficiency of its 10m fully self-propelled scissor lift platforms. Our after-sales service system is designed to address every stage of the equipment lifecycle—from installation, training, and daily maintenance to rapid troubleshooting and lifecycle support. Below is a detailed breakdown of our tailored after-sales services:

1. Comprehensive Warranty Policy

Standard Warranty Period: 12 months (core components: 24 months).

Core components include hydraulic pumps, motors, control systems, and structural frames (excluding wear-and-tear parts like tires, batteries, or hydraulic hoses).

Extended Warranty Options: Optional 6-month/1-year extensions available at purchase (discounted rates for bulk buyers).

Warranty Coverage: Free repair or replacement of defective parts due to manufacturing defects. Excludes damage from improper operation, accidents, or unauthorized modifications.

2. 24/7 Rapid Response Mechanism

Emergency Hotline: Dedicated service hotline (400/800 number) available 24/7 for immediate technical support.

On-Site Service Commitment: For critical failures (e.g., platform stuck at height, hydraulic system failure), our technicians will arrive at the site within 4–8 hours (urban areas) or 24 hours (remote regions).

Remote Diagnostics: Equipped with IoT-enabled telematics, we can remotely monitor equipment status, diagnose faults, and guide on-site staff to resolve minor issues (e.g., sensor calibration, software glitches) without delay.

3. Professional Maintenance & Inspection Services

Pre-Delivery Inspection (PDI): Before handover, our engineers conduct a full inspection to ensure the platform meets performance standards (e.g., lifting smoothness, safety sensor calibration, battery health).

Scheduled Maintenance Plans:

Basic Plan: Free monthly checkups (e.g., tire pressure, hydraulic oil level, brake function) included in the warranty.

Premium Plan (Optional): Quarterly deep inspections (e.g., structural stress testing, motor performance, control system updates) for high-frequency users (≥200 hours/month).

Maintenance Records: Digital service logs accessible via our customer portal, tracking all inspections, repairs, and part replacements for transparency.

4. Spare Parts Supply & Logistics

Global Spare Parts Warehouse: Centralized inventory in major regions (China, Southeast Asia, Europe, North America) ensures 95%+ part availability within 48 hours.

Original Parts Guarantee: All replacement parts are genuine Huichuang components, backed by a 6-month warranty.

Easy Ordering: Online parts portal with real-time stock updates; urgent orders can be expedited via air freight (additional cost).

5. Operator Training & Certification

Free Initial Training: Provided pre-delivery, covering:

Safety protocols (e.g., pre-operation checks, load limits, slope operation).

Control system operation (joystick, remote, platform panel).

Emergency procedures (e.g., lowering the platform manually, activating safety brakes).

Advanced Training (Optional): For large fleets, we offer customized training programs (e.g., seasonal maintenance, IoT system management) led by certified instructors.

Training Materials: Digital manuals, video tutorials, and quick-reference guides included for on-the-job reference.

6. Customized Support for Special Scenarios

Rental/Fleet Management: For rental companies or large enterprises, we provide tailored solutions:

Batch maintenance scheduling.

Asset tracking via GPS (optional).

Bulk parts orders with discounted logistics.

Harsh Environment Adaptation: For platforms used in extreme conditions (e.g., high dust, salt spray, or low temperatures), we offer:

Sealed hydraulic system upgrades.

Cold-weather battery kits (-30°C compatible).

Corrosion-resistant coating options.

7. Customer Feedback & Continuous Improvement

Post-Purchase Surveys: We follow up with customers 30/90 days after delivery to gather feedback on product performance and service quality.

Firmware Updates: Regular software upgrades (free of charge) to enhance safety features (e.g., improved anti-tipover algorithms, smarter battery management).

User Community: Access to our online forum for peer support, case studies, and best practice sharing among Huichuang platform users.

8. End-of-Life Support

Decommissioning Guidance: For platforms reaching the end of their lifecycle, we provide eco-friendly disposal solutions (e.g., recycling of steel frames, battery disposal compliance).

Trade-In Programs: In select regions, eligible older models may qualify for trade-in credits toward new Huichuang equipment.

Why Choose Huichuang’s After-Sales Service?

Global Presence: 20+ service centers in key markets, ensuring localized support.

Certified Technicians: All service staff undergo rigorous training and certification (ISO 18878 Aerial Work Platforms).

Transparency: Real-time service tracking via our customer app (check technician ETA, service history, and parts orders).

Conclusion: Huichuang Lift’s after-sales service goes beyond basic support—it’s a partnership to maximize your equipment’s uptime, safety, and ROI. With rapid response, genuine parts, and expert training, we ensure your 10m fully self-propelled scissor lift remains a reliable asset for years to come.