What Self-Propelled Scissor Aerial Work Platform?

A Self-Propelled Scissor Aerial Work Platform is a mobile, self-contained lifting device designed for safe, efficient elevated work. Its core structure features a scissors-like mechanism—multiple overlapping steel or aluminum arms (scissors) that fold and extend to raise or lower a platform. Powered by electric motors (for indoor/outdoor use) or internal combustion engines (diesel, gasoline), it operates without external traction, enabling independent movement across job sites.

Key components include a stable base, telescoping scissor arms, a control panel (often with remote or onboard interfaces), and a platform (with guardrails, tool trays, or specialized attachments). Typical working heights range from 10 ft 12 ft 13 ft 14 ft 15 ft 20 ft 40 ft, with load capacities of 1,000–5,000 lbs, accommodating 1–3 workers plus tools.

Ideal for construction, maintenance, and installation tasks, it excels in tight spaces (due to compact folded size) and uneven terrain (via rugged tires or tracks). Unlike boom lifts, its vertical reach prioritizes stability, making it a go-to for tasks like ceiling repairs, electrical installations, or warehouse stacking. Modern models often integrate smart features—load sensors, remote monitoring, or energy recovery systems—to enhance safety and efficiency.

View from the side10 ft 12 ft 13 ft 14 ft 15 ft 20 ft 40 ft self-propelled scissor Aerial work platform

Brand Background and Corporate Strength

As a leader in the global aerial work equipment industry, Huichuang Lift leverages its China-based headquarters featuring an 80,000㎡ intelligent factory to maintain full industrial chain capabilities—from core component R&D to final assembly. With over 300 patents, an annual production capacity of 15,000 units, and certifications including ISO9001, EU CE, and U.S. ANSI A92, our products are exported to over 120 countries. Committed to "safety, efficiency, and customization," we offer self-propelled scissor aerial work platforms (AWPs) spanning 10ft to 40ft, catering to diverse scenarios such as construction, power, municipal works, warehousing, and film production.

Full-Scale Product Portfolio: From Precision Tasks to High-Altitude Conquest

(I) Core Technical Parameter Comparison Table

| Model | Platform Height (ft) | Max Working Height (ft) | Platform Size (L×W, ft) | Load Capacity (lbs) | Scissor Layers | Power Type | Travel Speed (mph) | Gradeability | Battery Life (h) |

|---|---|---|---|---|---|---|---|---|---|

| HC-10 | 10 | 12 | 6×3 | 1000 | 3 | Electric (48V) | 3 | 25% | 8 |

| HC-12 | 12 | 14 | 6×3.5 | 1200 | 3 | Electric/Fuel | 4 | 30% | 6 |

| HC-13 | 13 | 15 | 7×4 | 1500 | 4 | Lithium Battery | 3.5 | 20% | 10 |

| HC-14 | 14 | 16 | 7×4.5 | 1800 | 4 | Diesel | 5 | 35% | 5 |

| HC-15 | 15 | 17 | 8×5 | 2000 | 4 | Hybrid | 4.5 | 25% | 7 |

| HC-20 | 20 | 23 | 10×6 | 3000 | 5 | Diesel | 6 | 40% | 4 |

| HC-40 | 40 | 45 | 15×8 | 5000 | 8 | Diesel | 8 | 45% | 3 |

Manned from the side 10 ft 12 ft 13 ft 14 ft 15 ft 20 ft 40 ft self-propelled scissor Aerial work platform

(II) Detailed Breakdown by Specification

1. HC-10 (10ft·Lightweight Pioneer)

Core Advantages: Compact design (folded dimensions ≤2.5×1.2×1.8m), ideal for indoor tight spaces like mall ceiling repairs, hotel pipe maintenance, and office equipment installation.

Key Features:

Triple-stage synchronized scissor structure with noise <65dB and operation stability ±15mm;

Full-height anti-fall guardrail (42-inch height), emergency stop button, and leakage protection system;

220V fast charging (4-hour full charge), lithium battery version extends runtime to 12 hours.

Application Scenarios: Chain store renovations, cleanroom maintenance in hospitals, and library shelf organization.

Price: Starting at $18,900 (includes standard guardrails and hydraulic system warranty).

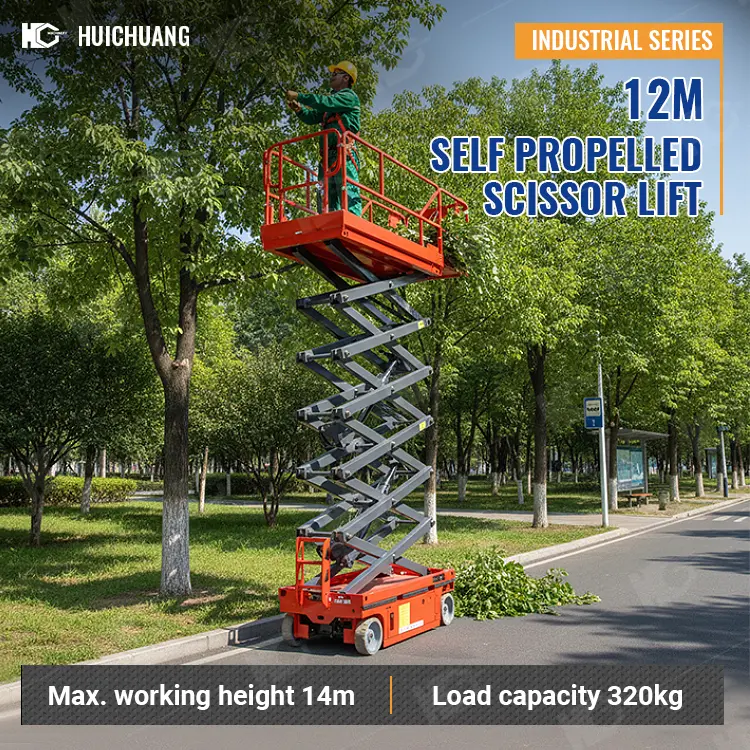

2. HC-12 (12ft·Versatile All-Rounder)

Core Advantages: Dual power options (electric/fuel) for indoor-outdoor flexibility, with a 1,200-lb capacity to carry 2 workers + 500 lbs of tools.

Key Features:

Smart load-sensing system with overload alerts;

Optional 360° rotating platform (extends working radius to 10ft);

Low-temperature lithium batteries (-20℃ operable) for northern winter use.

Application Scenarios: Property management landscaping, factory roof waterproofing, and billboard installation.

Price: Electric version $26,800.

3. HC-13 (13ft·Lithium Battery Expert)

Core Advantages: Industry-first fully lithium-powered design, zero emissions, and low maintenance for premium clients.

Key Features:

Energy recovery system (charges during descent, extending runtime by 30%);

Anti-slip steel platform (friction coefficient ≥0.8), improving safety by 60% in wet conditions;

Optional 5G remote monitoring (real-time tracking of position, height, and oil temperature).

Application Scenarios: Electronics factory cleanroom upgrades, museum artifact restoration, and high-end office curtain wall cleaning.

Price: $32,800 (includes 3-year battery warranty).

4. HC-14 (14ft·Diesel-Powered Favorite)

Core Advantages: Robust diesel engine (55kW power) for complex terrains, with a 35% gradeability.

Key Features:

Wide tracks (ground pressure ≤35kPa) for muddy/snowy surfaces;

Dual hydraulic pump redundancy (maintains basic operation if one pump fails);

Built-in engineer-grade diagnostic tool (3-minute fault localization).

Application Scenarios: Construction site material handling, power line inspections, and mountainous scenic area maintenance.

Price: $38,600.

5. HC-15 (15ft·Hybrid Benchmark)

Core Advantages: Hybrid mode (electric ascent + fuel travel) reduces energy consumption by 40% and operational costs by 25%.

Key Features:

Smart energy management algorithm (auto-switches optimal power mode);

Optional cargo hook (800-lb capacity);

Compliance with EU Stage V emission standards.

Application Scenarios: Urban greenery trimming, warehouse shelf installation, and cross-industrial park operations.

Price: $45,200.

6. HC-20 (20ft·Mid-Height Workhorse)

Core Advantages: 5-stage scissor structure achieves 23ft max height, with a 3,000-lb capacity for heavy equipment transport.

Key Features:

Dual redundant hydraulic lines (dual pumps/motors, extending component lifespan by 50%);

Auto-leveling system (corrects tilt <3° automatically);

Optional rear differential lock (80% improved snow/ice escape capability).

Application Scenarios: Bridge bearing inspections, industrial plant pipe installations, and large stadium roof cleaning.

Price: $68,500.

7. HC-40 (40ft·Ultra-High Conqueror)

Core Advantages: 8-stage scissor design reaches 45ft, setting a new benchmark for super-high-rise construction.

Key Features:

Dual independent control systems (local + remote) for precise ground guidance;

High-strength aluminum scissor arms (tensile strength ≥500MPa, 30% lighter than steel);

Aviation-grade aluminum guardrails (EN 10045-2 impact tested, wind resistance up to 12 levels).

Application Scenarios: Skyscraper curtain wall installation, ultra-high-rise building construction, and TV tower exterior equipment maintenance.

Price: $128,000.

This is the finished product of the self-propelled scissor aerial work platform in our factory warehouse. Our factory is experienced, mature in technology and can produce in batches, with great price advantages.

(III) Accessories List (Standard + Optional)

| Category | Standard Configuration | Optional Accessories |

|---|---|---|

| Safety Systems | Four-wheel hydraulic brakes, anti-roll protection frame | Dual-channel safety harness, collision radar (laser/IR) |

| Power Systems | Base battery/fuel tank (20L/50L capacity) | Quick-swap battery module (3-minute replacement), range extender (HC-40 optional) |

| Control Systems | Multilingual LCD panel, wireless remote control | Voice interaction system, AR-assisted interface (HC-20/40 optional) |

| Work Attachments | Non-slip mats, tool storage basket | Cargo hooks (800-3,000 lbs), insulated platform (electrician-specific) |

| Maintenance | Oil level sensor, filter replacement reminder | Remote OTA updates, auto-lubrication system (HC-15/20/40 optional) |

Global Leadership: From Manufacturing to Customized Solutions

(I) Full-Process Manufacturing Excellence

R&D Capabilities: A 200+ engineer team (including 15 PhDs) invests 5% of annual revenue in innovation, earning titles like "Top 10 Aerial Work Equipment Brands in China" and "Red Dot Design Award."

Smart Manufacturing:

10 automated production lines (80% welding robots, eco-friendly water-based paint coating);

Stringent quality testing: 127 durability tests per unit (2,000-hour full-load ascent/descent, -40℃~60℃ thermal cycling);

Premium materials: Scissor arms from Baosteel/ThyssenKrupp, hydraulic valves from Rexroth/Eaton.

Delivery Time: Standard models ship in 7 days; customized models in 15-30 days (including engineering design).

(II) Diversified Collaboration Models

1. OEM Customization Services

Scope: Custom exteriors (branded logos), interface languages (12 options), and core parameters (height/load/power type)—full turnkey solutions.

Success Stories:

Custom HC-15-Lite for a European rental company (15% lighter, 20% longer runtime, 30% lower operating costs);

HC-20-HD for a Southeast Asian construction group (4,000-lb load capacity, becoming local bridge construction standard).

Process:

Requirement Alignment (1-3 days) → Scheme Design (5-10 days) → Prototype Development (15-25 days) → Mass Production (30-45 days) → Delivery & Acceptance

2. Deep Customization Solutions

For extreme environments (nuclear, military, hazardous areas), we offer end-to-end customization:

Specialized Environment Adaptations:

Nuclear-grade anti-corrosion models (1,000-hour salt spray test, IAEA certified);

Explosion-proof platforms (Ex certification for oil/chemical plants);

High-altitude versions (operational at 5,000m with engine power compensation).

Value-Added Service Packages:

Global warranty (3-year full coverage, including consumables);

Smart O&M systems (real-time monitoring, 40% reduced downtime via predictive maintenance);

Used equipment buyback program (3-year residual value guarantee).

Why Choose Huichuang Lift?

Cost Advantage: Direct factory pricing from China, 30%-40% lower than European/American brands;

Technical Leadership: Patented scissor structures enhance stability by 25%, with 50% lower failure rates than industry averages;

Service Network: 32 global service centers (10 overseas warehouses), 24-hour response, 48-hour parts delivery.

Sustainability Commitment

Huichuang Lift practices green manufacturing, investing ¥20 million in 2023 to install rooftop solar panels (60% self-sufficient factory power). All new models feature energy-saving modes, reducing carbon emissions by 25% vs. traditional equipment. We pledge to achieve full carbon neutrality across our supply chain by 2030, creating value for clients while protecting the planet.

Our factory has a mature supply chain, if you have a bulk order, our production capacity is fully satisfied. The delivery cycle is guaranteed.

FAQs

Q1: Are there discounts for bulk procurement (e.g., 10+ units)? What is the specific discount range?

A: Huichuang Lift offers tiered pricing discounts for bulk orders (≥10 units), with the exact discount depending on the quantity, model configuration, and collaboration model:

Standard models (e.g., HC-10/12/15): 5%-8% discount for 10-20 units; 10%-15% discount for 20+ units;

Customized models (e.g., special height, load capacity, or functions): Additional 5%-10% R&D cost-sharing discount based on customization complexity;

Mixed procurement (multiple specifications): Up to 20% combined discount.

Note: Final discounts require negotiation based on specific configuration lists, delivery timelines, and payment terms.

Q2: Can I customize models during bulk procurement to meet project needs (e.g., load capacity, height, color, or functions)?

A: Yes, we support deep customization across the following dimensions:

Parameter customization: Adjust scissor layers (e.g., increasing HC-10 from 3 to 4 layers for stability), load capacity (e.g., upgrading HC-15 from 2,000lbs to 2,500lbs), or max working height (e.g., extending HC-20 from 23ft to 25ft);

Function customization: Add insulated platforms (for electricians), cargo hooks (1,000lbs capacity), 5G remote monitoring modules, or explosion-proof systems (Ex certification);

Aesthetic customization: Brand logo printing, custom color schemes (e.g., construction yellow, municipal blue), or multi-language operator interfaces (12 languages supported);

Certification customization: Rapid compliance modification for target markets (e.g., EU CE, U.S. ANSI, Australia AS/NZS).

Q3: What is the delivery timeline for bulk orders? Will production be affected by capacity constraints?

A: Delivery timelines vary by model type:

Standard models (no customization): Production completed within 7-15 working days after order confirmation, including domestic transportation to the port;

Customized models: Additional 3-8 weeks for engineering design and testing, with total lead time of 25-40 working days;

Large-scale orders (≥50 units): Dedicated production lines can be reserved to ensure on-time delivery.

Note: Huichuang Lift’s annual production capacity is 15,000 units, so standard orders face no capacity bottlenecks. Urgent orders can be prioritized with 24-hour overtime production.

Q4: What is covered under the after-sales warranty for bulk procurement? Are wearable parts included?

A: We provide a 3-year full machine warranty + 5-year extended warranty for core components (scissor arms, hydraulic pumps, motors). Coverage includes:

Free repairs: Non-human-induced damage to structural components, hydraulic systems, and control systems;

Wearable parts list**: Hydraulic oil, filters, tires/tracks (wearable items), batteries (lithium battery warranty: 2 years);

Global service: Overseas users can access local authorized service centers (48-hour on-site response) or request factory return (free shipping).

Q5: Do the machines comply with safety certifications for target markets (e.g., EU CE, U.S. OSHA)? Are additional certification fees required for bulk procurement?

A: All Huichuang Lift models are pre-certified for CE (EU), ANSI A92 (USA), GB/T 25755 (China), and other international standards, enabling direct export to 120+ countries.

For markets with special requirements (e.g., Australia AS/NZS 1418, Japan JIS), factories provide free certification document translation and supplementary testing (only small testing fees apply);

No extra certification fees for bulk procurement (costs are already factored into R&D).

Q6: Are standard accessories included in bulk procurement? What types of optional accessories are available, and what are their prices?

A: Standard configurations include:

Basic safety systems (anti-fall guardrails, emergency stop buttons, leakage protection);

Multilingual LCD control panels, wireless remote controls;

Non-slip mats, tool storage baskets;

1 set of universal hydraulic oil filters (free replacement during warranty).

Optional accessories (per unit):

Insulated platform (electrician-specific): 800-1,200;

Cargo hook (1,000lbs capacity): 500-800;

5G remote monitoring module: 1,500-2,000;

Quick-swap battery pack (diesel models optional): 3,000-5,000.

Q7: Does bulk procurement include operator training? What are the formats and contents of the training?

A: Free three-level training (theory + practical + assessment) is provided:

Basic operation training (2 days): Machine structure, startup/shutdown procedures, platform lifting control, and emergency handling;

Safety protocol training (1 day): Load limits, terrain adaptation, anti-tip measures, and PPE usage;

Advanced maintenance training (1 day, optional): Hydraulic system troubleshooting, battery care, and wearable part replacement (for equipment managers).

Training formats: On-site training (preferred) or online video lessons (with operation manuals and video libraries).

Q8: What payment methods are available for bulk procurement? Does it support installment payments?

A: Flexible payment options to meet diverse needs:

Standard payment: 30% deposit (order placement) + 60% balance before shipment + 10% quality deposit (paid 3 months post-acceptance);

Installment plans: 6/12-month installments (requires corporate credit verification, with bank-standard interest rates);

Rent-to-own: For large projects, "rental-to-purchase" agreements can be negotiated (rental payments offset procurement costs post-term).

Q9: How stable are the machines on complex terrains (e.g., mud, slopes)? Does bulk procurement include terrain adaptability upgrades?

A: Huichuang Lift models pass 35% gradeability tests (HC-14 and above), equipped with:

Wide-track chassis (ground pressure ≤35kPa) for muddy/snowy surfaces;

Auto-leveling systems (automatically corrects tilt <3°);

Optional terrain enhancement package (for 40ft+ models): Widened tracks (reducing ground pressure to 25kPa) and anti-slip chains (snow use).

Q10: How does Huichuang Lift handle decommissioned equipment or second-hand resale after bulk procurement?

A: We offer a second-hand equipment buyback program:

After 3 years of use, units can be repurchased at 30%-50% of original price (based on usage duration and maintenance records);

Refurbishment services are available (additional fees apply) to facilitate resale;

Asset depreciation plans are provided to reduce corporate tax liabilities.

Bulk procurement requires attention to customization needs, delivery timelines, after-sales support, and compliance. With its full industrial chain advantages (R&D-production-service integration), Huichuang Lift delivers end-to-end solutions from "equipment selection" to "full lifecycle management."

Contact Us

Room 203, Second Floor, Building 8, Phase Ⅱ, Zhizao Town, Jibei Street, Jiyang District, Jinan City, Shandong Province

Overseas Markets: 12 regional offices in Europe, North America, Southeast Asia, etc., with localized support.

Choose Huichuang Lift—the trusted expert in China’s intelligent aerial work solutions. We redefine safety through technology and deliver value through customization, empowering your journey to new heights.

Note: All prices are FOB China Qingdao port (tax-inclusive). Configuration and delivery details require consultation with our sales team. Technical parameters are based on lab tests; actual performance may vary with local regulations and operation manuals.