What is a Self-Propelled Electric Scissor Lift?

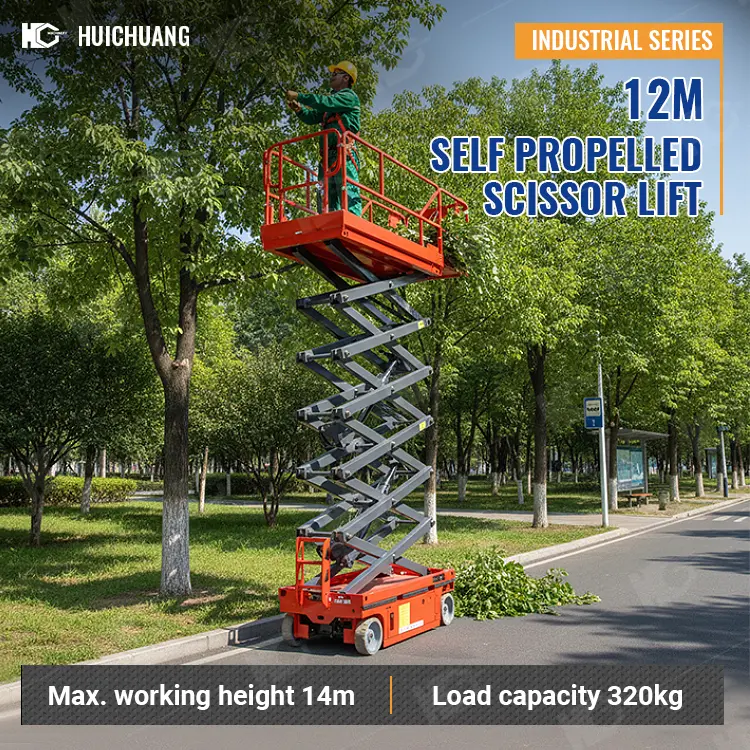

A self-propelled electric scissor lift is a type of aerial work platform designed to elevate personnel and equipment vertically using a scissors-like mechanism. Powered entirely by electricity, these lifts are engineered for mobility, precision, and safety in indoor and outdoor environments. Key features include:

Electric Drive: Environmentally friendly and quiet operation, ideal for warehouses, office buildings, and retail spaces.

Scissor Mechanism: Hydraulic or electric scissors arms provide stable, controlled lifting.

Self-Propulsion: Equipped with wheels or tracks for easy maneuverability without external assistance.

Height Adjustability: Typically ranges from 6 meters to 20+ meters, catering to diverse applications.

Safety Features: Includes guardrails, emergency stop buttons, and anti-slip platforms.

Commonly used in construction sites, maintenance operations, warehouse management, and facility upkeep, these lifts prioritize worker safety and operational efficiency.

296310.webp)

Why Procure Self-Propelled Electric Scissor Lifts from Jinan, China?

1. Robust Manufacturing Ecosystem

Jinan, the capital of Shandong Province, is a hub for advanced engineering and machinery manufacturing. The city hosts numerous factories specializing in aerial lifts, benefiting from:

Technical Expertise: Decades of experience in producing high-quality scissor lifts, with engineers trained in both domestic and international standards.

Innovation-Driven R&D: Collaboration between universities and manufacturers fuels technological advancements, such as energy-efficient batteries and smart controls.

Complete Supply Chains: Proximity to suppliers of critical components (hydraulics, batteries, motors) reduces production delays and costs.

2. Cost-Effective Solutions Without Compromising Quality

Chinese manufacturing, particularly in Jinan, offers high-value products at competitive prices due to:

Economies of Scale: Large-scale production lowers per-unit costs.

Streamlined Labor: Skilled yet affordable workforce enhances affordability.

Government Subsidies: Incentives for green energy and industrial innovation further reduce expenses.

Despite lower costs, Jinan manufacturers adhere to international certifications (CE, ISO, ANSI), ensuring reliability and safety compliance.

3. Tailored Customization and Flexibility

Jinan-based companies excel in customized solutions, allowing buyers to specify:

Platform size, load capacity, and lifting height.

Battery types (lithium-ion, lead-acid) for varying operational needs.

Add-ons like telescopic booms or rotating platforms.

This flexibility makes Jinan a go-to source for niche applications, from narrow-space warehouse lifts to heavy-duty construction models.

4. Strong Policy Support and Sustainability Focus

China’s national push for green energy and advanced manufacturing aligns with Jinan’s industrial goals:

Subsidies for Electric Equipment: Tax breaks and grants encourage eco-friendly designs.

Carbon Reduction Initiatives: Manufacturers prioritize energy-efficient models, reducing operational costs for buyers.

5. Efficient Logistics and Export Capabilities

Jinan’s strategic location in eastern China provides access to:

Advanced Transportation Networks: High-speed rail, highways, and ports (e.g., Qingdao Port) facilitate domestic delivery and global exports.

Competitive Shipping Costs: Proximity to major ports minimizes freight expenses for international buyers.

6. Global Reputation and Market Presence

Jinan manufacturers supply scissor lifts to over 100 countries, earning trust through:

Consistent Quality: Rigorous quality control systems minimize defects.

After-Sales Support: Comprehensive warranties, training, and maintenance services ensure long-term ROI.

How to Operate a Self-Propelled Electric Scissor Lift

Operating a Self-Propelled Electric Scissor Lift requires strict adherence to safety protocols and operational guidelines to ensure personnel safety and equipment functionality. Below is a detailed step-by-step guide:

I. Pre-Operation Preparation

Read the Manual

Familiarize yourself with the equipment’s technical specifications, load capacity, maximum height, and model-specific requirements.

Inspect Equipment and Environment

Ensure the ground is level, dry, and free of oil/water to prevent slipping.

Check for overhead obstacles (e.g., cables, pipes, branches).

Monitor weather conditions; avoid use during strong winds, rain, or lightning.

Verify hydraulic fluid, battery charge (electric models), and tire/track condition.

Confirm brakes, emergency stop button, guardrails, and warning lights are functional.

Equipment Check:

Environment Check:

Wear Personal Protective Equipment (PPE)

Safety helmet, non-slip shoes, and high-visibility vest (for outdoor work).

Secure loose clothing and tie back long hair.

Confirm Load Limits

Never exceed the maximum load capacity (typically 100–300 kg).

Distribute weight evenly to avoid imbalance.

II. Operation Steps

1. Starting the Equipment

Power On: Plug in the power cable (electric models) or start the engine (diesel models).

Release Brakes: Disengage the parking brake to enable movement.

Check Control Panel: Ensure no fault indicators (e.g., warning lights) are active.

2. Lifting and Lowering

Raise the Platform:

Hold the control handle and press the “Up” button (usually green). The scissor arms will lift the platform smoothly.

Maintain platform levelness to prevent tilting.

Lower the Platform:

Press the “Down” button (usually red). Lower the platform until it touches the ground.

Ensure no one is below during descent.

3. Moving the Equipment

Low-Speed Movement:

Move only when the platform is at its lowest position.

Use the joystick or control lever to move slowly forward or backward.

Steering:

In confined spaces, avoid sharp turns to prevent collisions with walls or shelves.

4. Working at Height

Maintain Stability: Keep your center of gravity within the platform. Avoid sudden movements.

No Overreaching: Never lean out beyond the guardrails.

Wind Precautions: Cease operations if outdoor wind speeds exceed 4 on the Beaufort scale.

III. Post-Operation Procedures

Lower and Shut Down

Return the platform to its lowest position. Turn off the power switch and unplug the cable (electric models).

Engage the parking brake to prevent unintended movement.

Cleaning and Inspection

Remove debris, oil, or ice from the platform (clear ice in winter to prevent slips).

Inspect for wear, cracks, or hydraulic leaks; report issues immediately.

Parking

Park on flat, dry surfaces away from fire hazards.

For long-term storage, disconnect the battery to prevent discharge.

IV. Safety Precautions

Avoid Unauthorized Use

Never operate the lift unattended or with unauthorized personnel.

Prohibit overloading or use with damaged components (e.g., leaking hydraulics, missing guardrails).

Emergency Protocols

In case of tilt, unusual noises, or loss of control, immediately press the Emergency Stop Button. Evacuate and contact maintenance.

If the platform stalls, avoid forced lifting; use manual release valves or professional tools.

Regular Maintenance

Monthly checks: Hydraulic fluid, battery electrolyte, tire pressure.

Annual inspections by certified technicians.

V. Special Scenario Tips

Confined Spaces: Use compact models and pre-plan movement routes.

Aerial Work Platform Coordination: Pair with scaffolding or roofing work only after installing fall protection nets.

Indoor Warehousing: Monitor ceiling heights to avoid shelf collisions.

Safe operation of a Self-Propelled Electric Scissor Lift hinges on strict adherence to protocols and familiarity with equipment capabilities. Operators must complete professional training and obtain certifications (e.g., CE certification). Jinan-manufactured lifts often include smart safety systems (e.g., automatic power-off, collision warnings), but human diligence remains critical. Regular maintenance and standardized management minimize risks and enhance efficiency.

Whether upgrading warehouse equipment or equipping a construction team, Jinan’s scissor lifts deliver unmatched safety and performance.

Self-Propelled Electric Scissor Lifts After-Sales Service Overview

When purchasing self-propelled electric scissor lifts from Jinan, China, robust after-sales service is a critical factor to ensure long-term operational efficiency and minimal downtime. Jinan-based manufacturers are known for their comprehensive support systems, which include warranties, maintenance plans, technical assistance, and more. Below is a detailed breakdown of the typical after-sales services offered:

1. Warranty Coverage

Most Jinan manufacturers provide comprehensive warranties (typically 1–3 years) covering:

Parts and Components: Free replacement of defective parts (e.g., hydraulic systems, batteries, control panels) during the warranty period.

Labor Services: Free repairs and adjustments conducted by certified technicians.

Exceptions: Normal wear and tear (e.g., tire damage, paint chipping) may require separate maintenance contracts.

Example: A Jinan-based brand might offer a 2-year full warranty for electrical components and a 5-year structural warranty for the scissor arms.

2. Local Service Networks

Jinan’s manufacturers maintain an extensive network of authorized service centers across China and globally, ensuring rapid response:

Domestic Coverage: Major cities (e.g., Beijing, Shanghai, Guangzhou) have dedicated service teams for emergency repairs.

Global Reach: Partnerships with distributors in over 100 countries provide localized support for international buyers.

Mobile Teams: Some companies deploy field technicians to remote sites for on-site troubleshooting.

Key Advantage: Jinan’s centralized location in Shandong Province ensures quick logistics to neighboring regions like Beijing, Tianjin, and Jiangsu.

3. Rapid Response Mechanisms

24/7 Technical Support: Hotlines and online platforms provide real-time troubleshooting guidance.

Emergency Repairs: Critical issues (e.g., hydraulic leaks, motor failures) are prioritized, with many centers guaranteeing 48-hour on-site service within mainland China.

Preventive Alerts: IoT-enabled lifts (common in Jinan models) send automated diagnostics to service teams for proactive maintenance.

4. Maintenance and Training Programs

Routine Maintenance Contracts:

Options for monthly, quarterly, or annual check-ups to inspect hydraulic systems, batteries, tires, and safety mechanisms.

Cost-effective packages for high-usage industries (e.g., warehouses, construction).

Operator Training:

Free or subsidized training sessions for new buyers, covering safe operation, emergency protocols, and basic maintenance.

Training materials provided in multiple languages (English, Spanish, Russian, etc.).

5. Spare Parts Availability

Local Warehousing: Major service centers stock critical spare parts (e.g., batteries, hydraulic hoses) to avoid delays.

Online Catalogs: Buyers can order genuine parts directly through manufacturer portals.

Long-Term Support: Even for older models, Jinan manufacturers typically retain part designs and tooling for decades.

Example: A Jinan scissor lift buyer in Germany can order replacement batteries via the manufacturer’s website with delivery in 10–15 days.

6. Preventive Maintenance (PM) Services

Jinan manufacturers emphasize predictive maintenance to extend equipment lifespan:

Condition Monitoring: Sensors track metrics like battery health, hydraulic pressure, and motor temperature.

AI-Driven Diagnostics: Advanced models use data analytics to predict component failures before they occur.

Seasonal Servicing: Specialized maintenance for extreme weather (e.g., winterizing hydraulic fluids).

7. Government-Backed Support

Jinan benefits from China’s industrial policies, which enhance after-sales reliability:

Subsidized Servicing: Some local governments fund maintenance programs for SMEs.

Certification Compliance: After-sales teams adhere to ISO 9001 (quality management) and ISO 14001 (environmental standards).

8. Customer Feedback and Improvement Loops

Post-Service Surveys: Buyers rate service quality, ensuring continuous improvement.

Warranty Extensions: Satisfied clients may qualify for extended warranties based on usage history.

Product Upgrades: Free or discounted upgrades (e.g., battery replacements with newer lithium-ion models).

9. Customized Service Plans

For large-scale buyers (e.g., construction firms, logistics companies):

Fleet Management Services: Centralized tracking and maintenance scheduling for multiple units.

Dedicated Account Managers: Personalized support for enterprise clients.

10. International Certification Compliance

Jinan manufacturers design after-sales services to meet global standards:

CE and ANSI Compliance: Servicing aligned with European and American safety regulations.

Multilingual Support: Technical documents and customer service available in key languages.

Why Jinan’s After-Sales Service Stands Out

Cost-Effective Warranties: Longer coverage periods compared to Western manufacturers.

Speed and Accessibility: Dense service networks and mobile teams minimize downtime.

Technology-Driven Maintenance: IoT and AI integration enhance predictive care.

Global Trust: Over 100 countries rely on Jinan lifts, backed by consistent service quality.

When purchasing a self-propelled electric scissor lift from Jinan, prioritize manufacturers with:

Transparent warranty terms.

Local service centers in your region.

Proven track records in after-sales responsiveness.

By leveraging Jinan’s robust after-sales ecosystem, businesses can maximize equipment lifespan, reduce operational risks, and ensure compliance with safety standards.

Conclusion: Jinan as a Leader in Aerial Work Platform Innovation

For businesses seeking reliable, cost-effective self-propelled electric scissor lifts, Jinan, China, offers unparalleled advantages. Its blend of technical prowess, affordability, and sustainable practices positions it as a global leader in aerial lift manufacturing. By sourcing from Jinan, companies gain access to state-of-the-art equipment that enhances workplace safety and productivity while optimizing budgets.

Whether upgrading a warehouse fleet or equipping a construction team, Jinan’s scissor lifts deliver unmatched value, making them a smart choice in today’s competitive market.