A self propelled mobile scissor lift table is one of the most efficient and widely used aerial work platforms for indoor and outdoor operations that require stable vertical lifting. Designed for safety, productivity, and ease of use, this type of scissor lift has become standard equipment in construction, warehousing, manufacturing, facility maintenance, and rental fleets worldwide.

This article provides a clear, practical introduction to the self-propelled scissor lift table—what it is, how it performs, how to use it correctly, where it works best, and how to source it in bulk from China factory with confidence.

No exaggerated claims, no unnecessary jargon—just usable information.

What Is a Self Propelled Mobile Scissor Lift Table ?

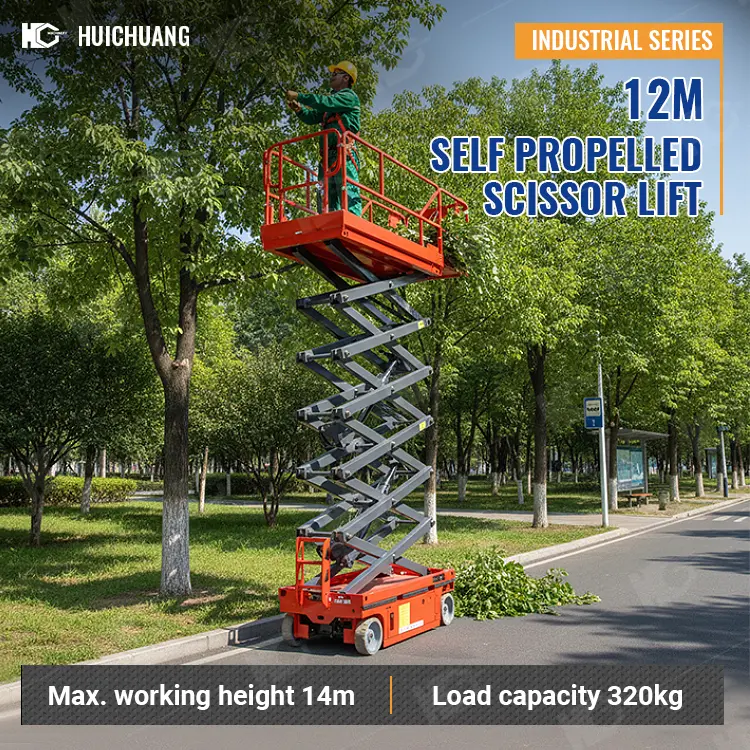

A self propelled mobile scissor lift table is a motorized lifting platform that can drive, steer, and elevate without external towing. The “12m” refers to its maximum working height, which usually corresponds to a platform height of around 12 meters, allowing operators to safely reach up to 14 meters.

Unlike manual or semi-electric lifts, a self-propelled model:

Moves under its own power

Can be driven at full height (low speed)

Requires only one operator

Eliminates repositioning downtime

In short, it lifts people and productivity at the same time.

Core Performance Specifications (Typical)

While specifications vary slightly by Huichuang lift manufacturer, a standard 12m self propelled mobile scissor lift table typically offers the following:

| Item | Typical Specification |

|---|---|

| Platform Height | ~12 m |

| Working Height | ~14 m |

| Load Capacity | 230–320 kg |

| Platform Size | Approx. 2.3 × 1.1 m |

| Extension Deck | 0.9–1.0 m |

| Drive System | Electric motor |

| Power Source | Battery (24V / 48V) |

| Gradeability | 20–25% |

| Turning Radius | Zero or small |

| Machine Weight | 2,800–3,200 kg |

| Controls | Platform + ground |

These parameters make the 12m model suitable for two workers plus tools, while maintaining stability and maneuverability.

Why Choose a Self Propelled Scissor Lift?

The 12m height range is considered a sweet spot in the scissor lift market.

Balanced Height and Cost

High enough for most industrial and commercial tasks

More affordable than 14m–16m models

Lower operating and transport costs

Strong Load Capacity

Easily supports personnel and materials

Stable platform with extension deck

Versatile for Indoor and Outdoor Use

Electric drive for indoor environments

Solid tires and safety systems for outdoor sites

Most buyers choose 12m because it covers 80% of real-world applications without unnecessary cost.

Key Features That Matter in Real Use

1. Self Propelled Drive System

The defining feature of this machine is self-propelled movement. Operators can:

Drive the lift directly to the work area

Adjust position without lowering the platform

Save time and labor

This is especially valuable in large warehouses or construction sites where repositioning happens frequently.

2. Stable Scissor Structure

The scissor mechanism:

Uses high-strength steel

Maintains vertical alignment

Reduces sway at height

Stability is not optional at 12 meters—it’s essential.

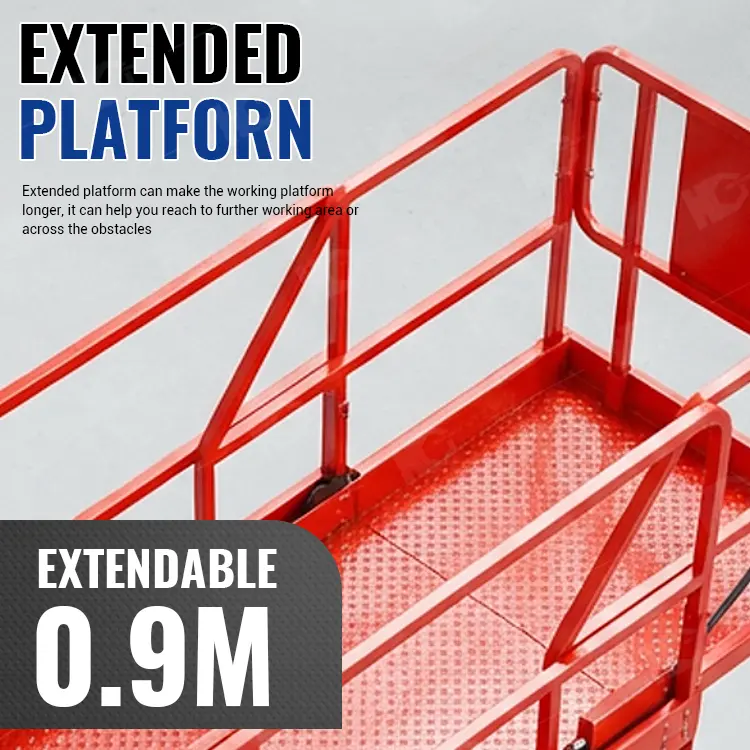

3. Extension Platform

Most 12m scissor lifts include a sliding extension deck, allowing operators to:

Reach over obstacles

Work along walls or structures

Reduce repositioning

This small feature has a big impact on productivity.

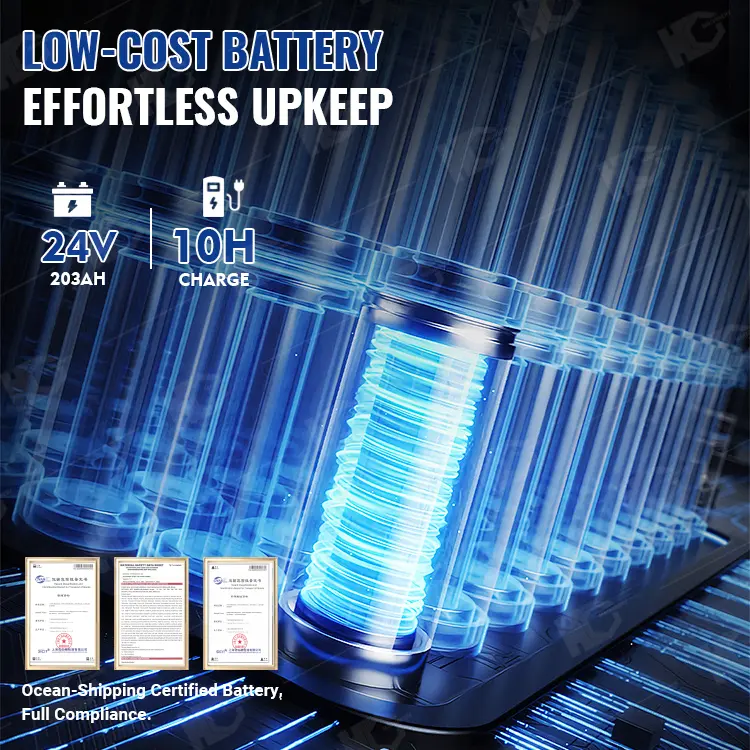

4. Electric Power System

Electric self propelled scissor lifts offer:

Zero emissions

Low noise

Lower maintenance costs

This makes them ideal for:

Factories

Warehouses

Shopping malls

Airports

Indoor construction

Low-cost battery maintenance, resulting in lower operating costs.

5. Integrated Safety Systems

A reliable 12m scissor lift table includes:

Emergency stop buttons

Tilt protection

Overload sensors

Pothole protection

Automatic braking

These systems protect both operators and equipment.

How to Use a Self Propelled Scissor Lift (Practical Steps)

Proper operation improves safety and machine lifespan.

Step 1: Pre-Operation Inspection

Check:

Battery level

Hydraulic oil

Tires and wheels

Guardrails and controls

Five minutes of inspection prevents hours of downtime.

Step 2: Enter the Platform Safely

Close and secure the safety gate

Wear required PPE

Confirm load does not exceed capacity

Step 3: Position the Lift

Drive the lift to the work area

Ensure ground is level and firm

Avoid slopes beyond rated gradeability

Step 4: Elevate the Platform

Raise the platform smoothly

Monitor stability and alarms

Use extension deck if needed

Step 5: Perform Work at Height

Keep tools organized

Avoid leaning over guardrails

Move lift slowly if repositioning at height

Step 6: Lower and Power Off

Lower platform fully

Drive to storage or charging area

Turn off power and charge batteries

Correct usage is simple, but discipline makes it safe.

No need for frequent climbing up and down to adjust settings on this scissor lift. It can be easily operated by a single person, saving time and costs.

Dual-control efficiency supports dual-position operation.

Main Application Scenarios

Construction and Installation

Ceiling and wall installation

Electrical and mechanical work

Fire protection systems

Warehousing and Logistics

High-rack maintenance

Lighting replacement

Inventory system installation

Its application in warehouses makes logistics more efficient.

Manufacturing Plants

Equipment maintenance

Pipeline installation

Overhead system servicing

Facility Management

Shopping malls

Airports

Exhibition centers

Stadiums

Rental Companies

High demand model

Easy training

Low maintenance

The 12m self propelled scissor lift is a core asset, not a niche tool.

Indoor vs Outdoor Use Considerations

While electric scissor lifts work both indoors and outdoors, keep in mind:

Indoor use: ideal conditions

Outdoor use: ensure firm ground and minimal wind

Avoid uneven terrain unless designed for it

For rough terrain, diesel scissor lifts may be more suitable, but for most applications, electric 12m models perform well.

Maintenance and Operating Costs

One reason buyers prefer self propelled scissor lifts is predictable maintenance.

Routine Maintenance Includes:

Battery charging and replacement

Hydraulic system inspection

Lubrication

Safety system checks

There is:

No engine oil

No fuel system

Fewer moving parts

This keeps lifetime cost low and uptime high.

How Long Does a Scissor Lift Last?

With proper maintenance:

Service life: 8–10 years

Batteries: 3–5 years

Hydraulic components: long-term serviceable

Quality manufacturing matters more than brand labels.

How to Choose the Right 12m Model

Before buying, confirm:

Required load capacity

Platform size and extension length

Indoor or outdoor use ratio

Spare parts availability

Avoid overspecification—it increases cost without adding value.

How to Buy Self Propelled Scissor Lift Tables in Bulk from China

China is one of the world’s largest manufacturers of scissor lifts, offering strong cost advantages and scalable production.

Why Source from China?

Competitive factory pricing

Mature manufacturing supply chains

Customization options

Bulk order discounts

Huichuang Lift is a self-propelled scissor lift table manufacturer from China. With over 13 years of industry experience, we provide customized and feasible scissor lift table solutions. As a professional factory, we have a complete supply chain and after-sales service system, ensuring you have no worries about equipment maintenance.Bulk purchases will get you a better price.

Typical Factory Direct Pricing (Reference Only)

Prices vary by configuration, but typical EXW or FOB China prices for a 12m self propelled scissor lift table often fall within:

USD 6,800 – 10,800 per unit (bulk orders)

Final pricing depends on:

Quantity

Certification

Battery type

Shipping method

If you'd like to learn more about Scissor Lift pricing, you can read our article: How Much Does a Scissor Lift Cost? A Complete Price Breakdown for Buyers and Renters. The prices listed here are for reference only, as prices fluctuate due to market influences. If you are currently planning to purchase a lift, you can contact us directly to get the latest prices.

MOQ and Lead Time

MOQ: 1–3 units (often negotiable)

Production time: 20–35 days

Bulk orders: faster scheduling

Certifications to Request

CE (Europe)

ISO 9001

ANSI (if required)

Test and inspection reports

Never skip certification verification.

Shipping and Logistics

Common shipping: 40HQ containers

Units per container: typically 2–4

Choose experienced freight forwarders

Plan logistics early to avoid delays.

Tips for Importers and Distributors

Request real factory videos

Ask for load and safety test data

Confirm spare parts supply

Clarify warranty terms

Avoid unrealistically low quotes

A reliable supplier answers clearly. A risky one avoids details.

Choose scissor lift vs boom lift

Choosing between a scissor lift and a boom lift depends on how and where you work. A scissor lift moves straight up and down, offering a large, stable platform and higher load capacity. It’s ideal for indoor maintenance, warehousing, and tasks that require lifting people and tools vertically. A boom lift, on the other hand, provides horizontal and articulated reach, allowing access over obstacles and into hard-to-reach areas. Boom lifts suit outdoor construction, facade work, and uneven terrain. In short, choose scissor lifts for vertical efficiency and boom lifts for flexible reach.

Final Thoughts

A self propelled mobile scissor lift table is one of the most practical investments in modern access equipment. It offers a balance of height, safety, efficiency, and cost that suits a wide range of industries.

When chosen correctly and sourced responsibly—especially through bulk procurement from reliable Chinese factories—this equipment delivers strong long-term value, low operating cost, and dependable performance.

In the world of working at height, reliability is not a feature.

It’s the baseline.

And a well-built 12m self propelled scissor lift table meets that baseline every single day.