When logistics managers, warehouse operators, or factory owners search for “Heavy Duty Mobile Loading Ramp for Containers & Trucks”, their intent is clear: they need a safe, reliable, and efficient way to load and unload goods. Whether it’s a forklift driving into a container, or trucks being unloaded quickly, the right mobile loading ramp can make the difference between smooth operations and costly downtime.

What is a Mobile Loading Ramp?

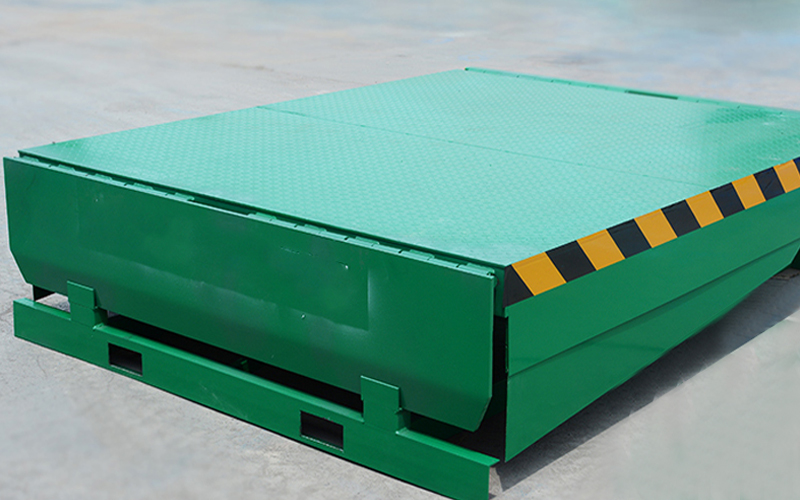

A mobile loading ramp (also known as a movable dock ramp or portable loading dock) is a piece of equipment designed to bridge the height difference between the ground and a truck or shipping container.

Key Features:

Portable design: Equipped with wheels or casters for easy movement.

Hydraulic adjustment: Allows the ramp height to match different truck beds.

Heavy-duty capacity: Designed to support forklifts carrying heavy pallets.

Safety rails & anti-slip surface: Ensures safe forklift operation.

Why Choose a Heavy Duty Mobile Loading Ramp?

Not all ramps are created equal. Light-duty models may suffice for small warehouses, but heavy duty ramps are crucial for industries with high cargo volumes.

Advantages of Heavy Duty Ramps:

High Load Capacity

Typically supports 8–15 tons (some models up to 30 tons).

Suitable for forklifts carrying multiple pallets at once.

Durability

Made from high-strength steel with anti-corrosion coating.

Designed to withstand daily use in harsh environments.

Time Efficiency

Forklifts can drive directly from ground to container.

Speeds up loading/unloading by 30–50% compared to manual methods.

Flexibility

Works with different truck heights (usually 1.1m–1.8m).

Can be moved to different areas of the warehouse yard.

Safety

Non-slip grating ensures forklifts won’t skid.

Side guardrails prevent accidents.

Technical Specifications of a Heavy Duty Mobile Loading Ramp

Typical specifications for a 12-ton hydraulic mobile ramp:

Capacity: 8–15 tons

Ramp Length: 10–12 meters

Width: 2–2.2 meters

Height Adjustment Range: 1.1–1.8 meters

Material: Q235 structural steel

Surface: Anti-slip steel grating

Operation: Manual or electric hydraulic pump

Mobility: Solid tires or PU wheels for easy movement

Applications of Mobile Loading Ramps

Logistics companies: Loading and unloading trucks quickly.

Factories: Moving raw materials into production areas.

Warehouses: Handling pallets, crates, and heavy cargo.

Ports and rail stations: Efficient container operations.

Agriculture: Transporting bulk goods like grain or equipment.

Cost of Heavy Duty Mobile Loading Ramp

When searching online, buyers often want to know “How much does a heavy duty mobile ramp cost?”

Factory Price in China:

8-ton ramp: USD 3,500–4,500

10-ton ramp: USD 4,800–6,000

12–15 ton ramp: USD 6,500–9,000

European/US Market Price: Usually 20–30% higher due to shipping and dealer margins.

Rental Price: Around USD 50–100/day, depending on location.

Tip for buyers: If you have long-term use, purchasing directly from a China manufacturer can save up to 40% compared to renting or buying locally.

How to Choose the Right Heavy Duty Mobile Loading Ramp

1. Determine Your Capacity Needs

Light cargo → 6–8 tons.

Standard forklifts + pallets → 10–12 tons.

Heavy machinery → 15 tons or more.

2. Check Compatibility with Trucks

Confirm truck/container bed height.

Choose a ramp with hydraulic adjustment to fit multiple vehicle types.

3. Safety Features

Look for side guardrails, anti-slip surface, and secure chains.

Check if the hydraulic system includes a safety valve to prevent sudden drops.

4. Mobility

If you need frequent repositioning, choose a ramp with solid rubber tires.

For fixed locations, stationary dock ramps may be cheaper.

5. Certification

Ensure compliance with CE, ISO9001, ANSI standards.

Safety Guidelines for Using a Mobile Loading Ramp

Inspect Before Use: Check hydraulic system, tires, and surface.

Load Evenly: Avoid side tilting by driving forklifts straight.

Use Safety Chains: Secure ramp to the truck to prevent shifting.

Speed Control: Forklifts should move slowly on the incline.

One Vehicle at a Time: Never allow two forklifts on the ramp simultaneously.

Weather Awareness: Avoid slippery conditions; use anti-slip mats in rain or snow.

Maintenance of Hydraulic Mobile Loading Ramps

Proper care extends the ramp’s lifespan (usually 8–10 years).

Hydraulic Oil: Replace annually.

Weld Inspection: Check for cracks every 6 months.

Surface Cleaning: Keep grating free of debris.

Lubrication: Grease moving parts regularly.

Tire Maintenance: Replace worn tires promptly.

Future Trends in Mobile Loading Ramps

Electric-powered hydraulic systems for faster height adjustment.

Smart monitoring sensors to detect overloads.

Lightweight steel alloys for easier mobility.

Eco-friendly coatings for longer anti-rust protection.

Why choose Huichuang Lift?

Huichuang Lift is a professional manufacturer of aerial work platforms and material handling equipment in China. Our factory covers over 30,000㎡, equipped with advanced CNC cutting, automatic welding, and powder coating production lines to ensure precision and durability in every product. We specialize in designing and producing diesel self-propelled boom lifts, electric scissor lifts, mobile loading ramps, and custom hydraulic lifting solutions. With an annual capacity of more than 500 units, Huichuang Lift is able to meet bulk orders while maintaining strict quality control. All products are manufactured in compliance with international standards such as CE, ISO9001, and ANSI, making them suitable for global markets in logistics, construction, warehousing, and maintenance industries. By integrating innovation, safety, and efficiency, Huichuang Lift is committed to providing reliable lifting solutions and long-term value for partners worldwide.

Conclusion

A Heavy Duty Mobile Loading Ramp for Containers & Trucks is an essential tool for modern logistics, offering efficiency, safety, and flexibility. Whether you run a busy warehouse, operate a freight yard, or manage a factory, investing in the right ramp can dramatically improve productivity.

To recap, buyers searching for this product usually want to know:

What a heavy duty mobile loading ramp is.

Why hydraulic ramps are more efficient.

The cost and capacity ranges.

How to choose the right model.

Safety and maintenance practices.

By considering these factors, you can ensure your investment delivers maximum value while keeping your operations safe and efficient.

FAQs

1. What is the load capacity of a heavy duty mobile loading ramp?

Most ramps support 8–15 tons, while customized models can handle up to 30 tons, suitable for heavy forklifts and large cargo.

2. Can the ramp height be adjusted for different trucks?

Yes. The hydraulic system allows height adjustment between 1.1m–1.8m, matching various truck and container heights.

3. What material is used to manufacture the ramp?

High-strength Q235 structural steel with an anti-slip grated surface and anti-rust coating ensures durability and safety.

4. Is the ramp mobile or fixed?

Both options are available. The mobile loading ramp has wheels for repositioning, while a fixed dock ramp is permanently installed.

5. How much does a heavy duty mobile ramp cost?

Factory price in China ranges from USD 3,500–9,000, depending on load capacity, size, and hydraulic system configuration.

6. What safety features are included?

Safety chains, anti-slip steel grating, side guardrails, hydraulic safety valves, and emergency lowering functions are standard.

7. How long is the service life of the ramp?

With proper maintenance, a heavy duty ramp typically lasts 8–10 years under daily use.

8. Can the ramp be customized?

Yes. Buyers can request custom width, capacity, color, logo branding, and power options (manual or electric hydraulic pump).

9. What certifications should I check before purchase?

Reliable manufacturers provide CE, ISO9001, or ANSI certification, ensuring international safety compliance.

10. What maintenance is required for the hydraulic ramp?

Regularly check hydraulic oil (replace yearly), inspect welds and grating, lubricate moving parts, and ensure tires are in good condition.

717.webp)