What is a Mobile Loading Ramp?

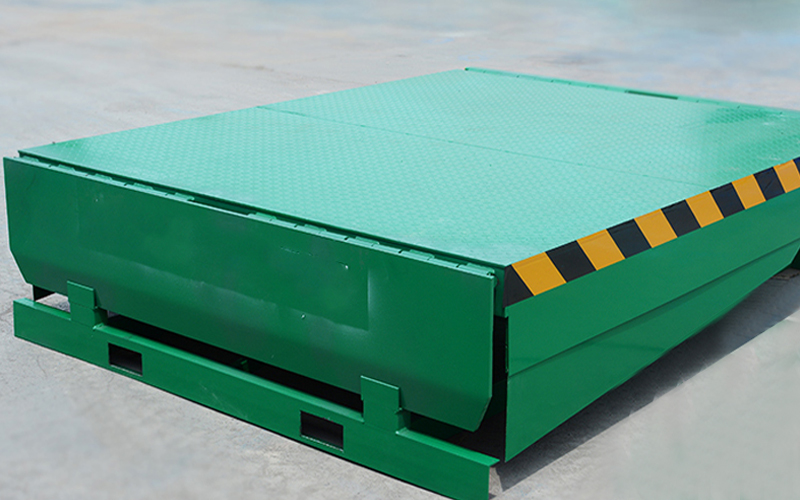

A Mobile Loading Ramp (also called a portable truck ramp or mobile dock board) is a retractable, heavy-duty steel or aluminum structure designed to bridge the gap between truck beds and loading docks, floors, or ground surfaces. Unlike fixed ramps or permanent loading docks, it is portable, foldable, and quick-deployable, making it ideal for dynamic logistics environments where space, time, and flexibility are critical.

Its primary function is to eliminate the "height gap" between low-clearance trucks (e.g., delivery vans, container trailers) and loading platforms, enabling safe, efficient transfer of palletized goods, crates, or bulk materials via forklifts, pallet jacks, or manual handling. Mobile ramps are widely adopted in logistics hubs, warehouses, manufacturing plants, and construction sites to streamline unloading/loading processes and reduce reliance on fixed infrastructure.

Core Parameters & Specifications Table

Below are key technical specifications of Huichuang Lift’s mobile loading ramps, categorized by model (rated for 1–8 ton forklift loads):

| Model | Max Load Capacity | Platform Length (ft) | Platform Width (ft) | Folded Thickness (in) | Extended Height (in) | Slope Angle | Material | Power Type | Applicable Truck Types |

|---|---|---|---|---|---|---|---|---|---|

| MLR-1T | 1 ton (2,200 lbs) | 4 | 3 | 4 | 7–10 | 12°–15° | Carbon Steel | Manual (hydraulic) | Small delivery vans, pickup trucks |

| MLR-3T | 3 tons (6,600 lbs) | 6 | 4 | 5 | 8–12 | 10°–12° | Aluminum Alloy | Electric (battery) | Medium trucks, container trailers |

| MLR-5T | 5 tons (11,000 lbs) | 8 | 4.5 | 6 | 9–14 | 8°–10° | High-Strength Steel | Electric + Hydraulic | Heavy-duty trucks, semi-trailers |

| MLR-8T | 8 tons (17,600 lbs) | 10 | 5 | 7 | 10–16 | 7°–9° | Aircraft-Grade Aluminum | Hydraulic (dual pump) | Industrial semi-trailers, bulk cargo vans |

Key Features & Design Innovations

Foldable & Portable: Collapses to 4–7 inches thick for easy storage in truck beds, closets, or warehouse corners. Unfolds in <5 minutes via hydraulic or manual pumps.

Anti-Slip Surface: Textured steel/aluminum platform with rubberized edges prevents pallet slippage, even in wet or icy conditions.

Reinforced Structure: Welded steel frames with cross-bracing and powder-coated finishes resist corrosion, impacts, and heavy loads.

Adjustable Height: Some models (e.g., MLR-5T/8T) feature telescopic legs to adapt to varying truck bed heights (48–72 inches).

Safety Guardrails: Optional 42-inch-high guardrails with self-closing gates protect operators and prevent load rollback.

Base Price Range by Model (FOB Jinan, China)

Huichuang Lift’s mobile ramps are priced based on load capacity, material, and features. Below are standard prices for our four core models (2025 pricing, subject to market fluctuations):

| Model | Max Load Capacity | Base Price (USD) | Key Features Included |

|---|---|---|---|

| MLR-1T | 1 ton (2,200 lbs) | 1,800–2,200 | Carbon steel frame, manual hydraulic pump, 4ft platform, 12°–15° slope, basic anti-slip surface. |

| MLR-3T | 3 tons (6,600 lbs) | 3,800–4,500 | Aluminum alloy frame, electric pump (battery-powered), 6ft platform, 10°–12° slope, rubberized edges. |

| MLR-5T | 5 tons (11,000 lbs) | 6,500–7,800 | High-strength steel frame, dual-mode (electric + hydraulic) pump, 8ft platform, 8°–10° slope, reinforced cross-bracing. |

| MLR-8T | 8 tons (17,600 lbs) | 11,500–13,200 | Aircraft-grade aluminum frame, hydraulic dual-pump system, 10ft platform, 7°–9° slope, optional guardrails (add $500). |

Primary Application Scenarios & Data-Driven Benefits

1. Logistics & E-Commerce Warehouses

Challenge: Traditional fixed docks require trucks to back into tight bays, wasting 15–20 minutes per unloading session. Small trucks (e.g., UPS/FedEx delivery vans) often can’t access docks due to height mismatches.

Solution: MLR-3T/5T ramps bridge gaps in 30 seconds, enabling "curbside unloading" without dock access.

Data: A logistics hub in Shanghai reduced unloading time per small truck from 25 minutes to 8 minutes (68% improvement) and cut labor costs by 40% (from 4 workers to 1 operator with a forklift).

2. Manufacturing Plants

Challenge: Raw material deliveries (e.g., steel coils, plastic pallets) often arrive via flatbed trucks with low ground clearance, making manual unloading (via pallet jacks) time-consuming and unsafe.

Solution: MLR-5T ramps (rated for 5-ton loads) allow forklifts to directly access flatbeds, eliminating manual handling.

Data: An automotive parts factory in Guangzhou increased raw material unloading efficiency by 50% (from 8 tons/hour to 12 tons/hour) and reduced workplace injuries by 75% (no more manual lifting).

3. Cold Chain Logistics

Challenge: Refrigerated trucks (reefers) require quick unloading to maintain product integrity. Fixed ramps are often too far from loading docks, prolonging door-open times (critical for perishables).

Solution: MLR-3T aluminum ramps (lightweight, corrosion-resistant) are used to connect reefers to warehouse loading bays in seconds.

Data: A food distribution center in Beijing reduced reefer door-open time from 12 minutes to 4 minutes per truck, cutting energy costs by $1,200/month and extending food shelf life by 1.5 days.

4. Construction Sites

Challenge: Bulk materials (e.g., cement bags, lumber) are often delivered via dump trucks or flatbeds parked on uneven terrain, making manual unloading dangerous and inefficient.

Solution: MLR-8T heavy-duty ramps (with adjustable legs) stabilize on uneven ground and support 8-ton loads, enabling forklift access to rough-terrain vehicles.

Data: A construction company in Shenzhen reduced material handling accidents by 90% (no more slipping on uneven surfaces) and cut unloading labor from 6 workers to 2 per shift.

Competitive Advantages of Huichuang Lift Mobile Ramps

As a leading manufacturer based in Jinan, China, Huichuang Lift’s mobile loading ramps outperform competitors in key areas:

1. Durability & Load Capacity

Material Excellence: Heavy-duty models (MLR-5T/8T) use Q345B steel (tensile strength ≥470 MPa) or 6061-T6 aluminum (strength-to-weight ratio 1.8g/cm³), ensuring 50% longer lifespan than standard ramps.

Load Testing: Each ramp undergoes 120% overload testing (e.g., MLR-5T tested with 6 tons) to guarantee safety margins. Competitors typically test at 100% capacity.

2. Portability & Ease of Use

Folded Size: MLR-3T collapses to 4"×6"×8ft (thickness×width×length), fitting in a 5ft truck bed. Rivals often require 10ft storage space.

Deployment Speed: Hydraulic models unfold in <5 minutes; manual pumps (for MLR-1T) take <3 minutes. Industry average is 8–10 minutes.

3. Customization & OEM Support

Tailored Solutions: Clients can specify platform length (4–12ft), width (3–6ft), slope angle (7°–15°), and color (e.g., safety yellow, industrial gray).

Branding Options: Add company logos, serial numbers, or custom labels via laser engraving or vinyl printing.

4. Global Compliance & Certification

Certifications: All ramps meet ISO 9001, CE (EU), ANSI A14.9 (USA), and GB/T 19155-2017 (China) standards for load safety and structural stability.

Export Expertise: With 10+ years of global experience, Huichuang Lift handles customs clearance, sea/air freight, and localized after-sales support in 30+ countries.

Huichuang Lift: Your Trusted Mobile Ramp Partner

Located in Jinan, Shandong Province—China’s "Capital of Logistics Equipment"—Huichuang Lift operates a 20,000㎡ factory equipped with automated welding robots, CNC cutting machines, and a 100,000-unit annual production capacity. Our services include:

1. OEM Customization

Parameter Adjustment: Modify load capacity (up to 15 tons), platform dimensions, or material (e.g., stainless steel for marine environments).

Function Upgrades: Add features like LED work lights, remote control operation, or tire pressure monitoring systems (TPMS).

2. Wholesale Distribution

Volume Discounts: Bulk orders (≥20 units) receive 15–25% off list prices. For example:

MLR-3T (standard): 3,800/unit→2,850/unit (20+ units).

MLR-8T (heavy-duty): 11,500/unit→8,625/unit (20+ units).

Global Logistics Support: Partner with DHL, Maersk, and local freight forwarders to ensure on-time delivery to ports in the USA, Europe, Southeast Asia, and the Middle East.

3. After-Sales Service

1-Year Warranty: Covers structural defects, hydraulic leaks, and motor failures.

On-Site Repairs: Deploy technicians to client sites within 48 hours for urgent issues (additional fees apply for remote regions).

Conclusion

Mobile loading ramps are indispensable tools for modern logistics, bridging the gap between efficiency and flexibility. Huichuang Lift’s mobile ramps—engineered in Jinan, tested to global standards, and tailored to client needs—empower warehouses, manufacturers, and logistics providers to reduce costs, enhance safety, and boost throughput. Whether you need a compact ramp for small vans or a heavy-duty model for semi-trailers, Huichuang Lift delivers solutions that move your business forward.

717.webp)