If your warehouse, dock, or construction site needs a faster, safer, and more flexible way to load and unload heavy goods, portable ramps for forklifts are a game changer. These ramps bridge the gap between ground level and truck beds, containers, or raised platforms—letting your forklift move freely without building a permanent dock. Let’s break down what they are, how they work, and how to choose the right one for your operation.

What Is a Portable Forklift Ramp?

A portable forklift ramp is a heavy-duty, movable steel structure designed to give forklifts easy access to trailers, containers, or elevated loading bays. It’s built for fast setup and removal, so you can use it anywhere you need to load or unload materials.

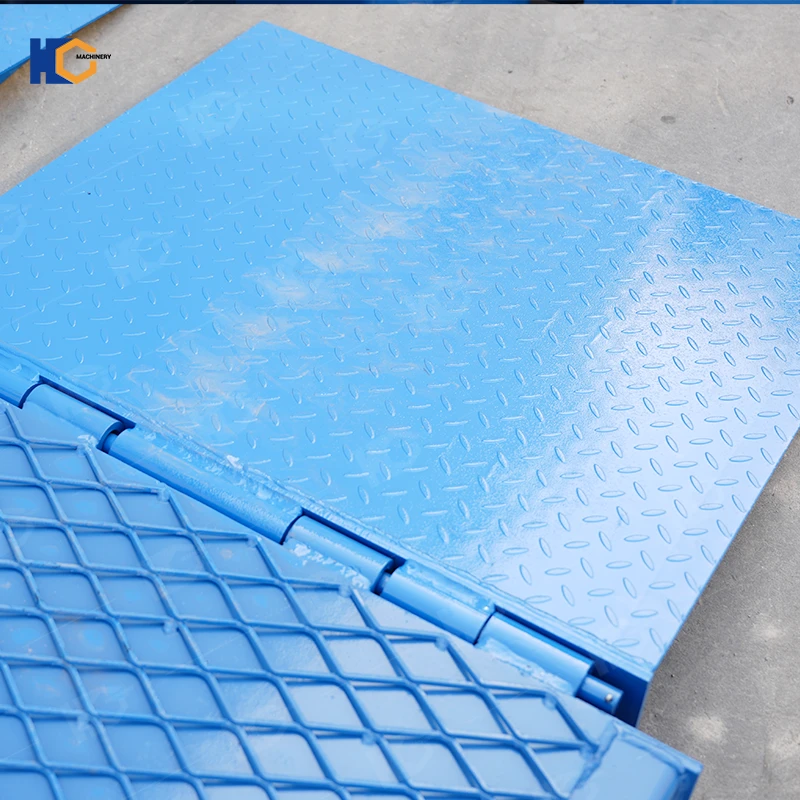

Most ramps have an adjustable height system (usually hydraulic or manual), safety chains, side curbs, and an anti-slip surface to keep things steady while forklifts move up and down.

Think of it as a mobile loading dock—strong, durable, and ready to go wherever your work takes you.

In a previous article, we highlighted the Mobile Loading Ramp, which can carry 15 tons. 15T Mobile Loading Ramp: The Ultimate Solution for Efficient Loading and Unloading.It can also handle forklift operations, container unloading, and truck unloading.

Why Businesses Love Portable Ramps

No Permanent Construction Needed

You don’t have to build a loading dock. Just roll out the ramp, adjust the height, and you’re good to go. Perfect for sites that rent space or move operations often.Saves Time and Labor

A forklift can drive straight from the ground into a truck or container. No need to transfer pallets by hand or use extra equipment.Highly Durable

Most portable forklift ramps are made of heavy-duty steel or aluminum and can handle loads from 10,000 lbs to 30,000 lbs (roughly 4.5–13.5 tons).Safe and Reliable

Features like anti-slip grating, safety chains, and side guard rails keep operators safe while loading on uneven or slippery ground.

Common Types of Portable Forklift Ramps

Steel Portable Ramps

Built for heavy-duty work. These are ideal for industrial warehouses, shipping yards, and logistics centers. They can handle multiple forklift loads without bending or warping.Aluminum Portable Ramps

Lighter and easier to move, but still strong. Great for smaller warehouses or delivery operations that need mobility.Hydraulic Portable Ramps

Equipped with a manual or powered hydraulic system for easy height adjustment—perfect for connecting to different trailer heights quickly.

Technical Specs (Typical Example)

| Specification | Details |

|---|---|

| Capacity | 15,000 – 30,000 lbs |

| Width | 6 – 8 feet |

| Length | 30 – 40 feet |

| Height Adjustment | 37 – 65 inches |

| Surface | Serrated steel grating (anti-slip) |

| Side Rails | 4 – 6 inches high |

| Mobility | Equipped with wheels or forklift slots |

| Material | Heavy-duty steel or aluminum |

How to Choose the Right Ramp

Check Your Forklift Weight and Load

Include the combined weight of the forklift and the heaviest pallet load. Always pick a ramp with at least 25% more capacity than your total weight.Consider the Usage Environment

Steel ramps for long-term heavy use.

Aluminum ramps for mobility and lighter loads.

Hydraulic ramps for multi-trailer operations.

Look for Safety Features

Anti-slip surfaces, secure locking chains, and durable side rails are must-haves.Maintenance and Storage

Choose a ramp that’s easy to clean and resistant to rust, especially if you work outdoors.

Typical Price Range

Portable forklift ramps vary widely in cost depending on capacity, length, and design. Here’s a general guide:

Small aluminum ramps: around $2,000–$4,000 USD (₦3.2 million–₦6.4 million)

Mid-size steel ramps: around $4,000–$7,000 USD (₦6.4 million–₦11.2 million)

Heavy-duty hydraulic ramps: around $7,000–$12,000 USD (₦11.2 million–₦19.2 million)

For factories and warehouses that need frequent container loading, the investment pays for itself through time saved, fewer accidents, and smoother workflow.

Maintenance Tips

Check hydraulic oil levels regularly (if applicable).

Inspect the surface grating for debris or damage.

Keep all bolts tight and rust-free.

Store in a dry area when not in use to extend lifespan.

Final Thoughts

A portable forklift ramp is one of those upgrades that quietly transforms your workflow. It boosts flexibility, improves safety, and saves you hours every week. Whether you’re managing a busy logistics yard, a manufacturing plant, or just need a reliable loading solution for your warehouse, a well-built ramp is worth every dollar.

If you’re sourcing directly from a Chinese ramp manufacturer, you can also cut costs significantly while customizing dimensions and weight capacity to fit your operation perfectly.