Choosing the right aerial work platform matters more than ever. As workplaces raise their safety standards, companies are shifting away from risky ladders and toward professional lifting equipment. Two of the most widely used options are the single man lift and the scissor lift. Although they both elevate workers to a safe working height, they are built for different environments, different tasks, and different budget levels.

This comprehensive guide delivers a deep comparison between the two, helping you understand their structure, specifications, functions, advantages, cost differences, applications, and which lift is best for your operation.

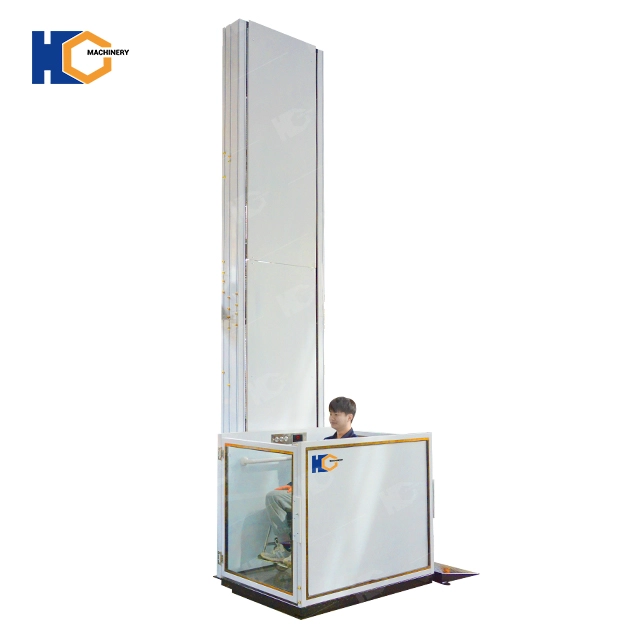

What Is a Single Man Lift?

A single man lift—also called a personnel lift, vertical mast lift, or man lift—is a compact, lightweight, vertical access machine designed for one operator and light tools. It uses a telescopic aluminum mast that extends straight upward.

Key traits include:

Narrow body (generally 0.74–0.80 m wide)

Very lightweight (200–600 kg)

Quiet electric or battery power

One-person platform

Suitable for tight indoor spaces

Single man lifts are extremely popular in warehouses, retail stores, malls, hospitals, airports, and maintenance facilities where mobility and compact size matter more than platform size.

What Is a Scissor Lift?

A scissor lift is a larger aerial work platform using a stack of crisscrossing metal supports that extend upward in a scissor-like pattern. It offers a much wider platform, higher load capacity, and the ability to lift multiple workers.

Typical features include:

Wide platform (1.0–2.5 m)

Load capacities from 230–450+ kg

Electric or diesel power

Indoor and outdoor models

Stable, heavy-duty platform for two or more people

Scissor lifts are widely used in construction, facility management, industrial maintenance, and outdoor job sites requiring larger tools and multiple workers.

Structural Differences: Mast vs Scissor Mechanism

Single Man Lift Structure

A single man lift uses a telescopic mast system, usually made from lightweight but high-strength aluminum. This allows for:

Smoother vertical movement

Lower machine weight

Smaller chassis footprint

Quiet operation

The mast structure is ideal for straight-up height access where lateral reach is unnecessary.

Scissor Lift Structure

A scissor lift uses steel scissor arms, driven by hydraulic cylinders that push the scissor stack upward. This design allows:

Large working platform

Higher lifting loads

More stability for multiple people

Wider base to support additional weight

The trade-off is that the lift becomes heavier, wider, and less suitable for tight indoor passages.

Typical Specifications Comparison

| Feature | Single Man Lift | Scissor Lift |

|---|---|---|

| Working Height | 4–14 m | 6–18 m |

| Platform Capacity | 120–200 kg | 230–450+ kg |

| Platform Size | Small, 1 person | Large, 2–4 people |

| Machine Width | 0.74–0.80 m | 0.76–1.25 m |

| Machine Weight | 200–600 kg | 900–3500 kg |

| Power Source | Battery / AC electric | Battery (indoor) or diesel (outdoor) |

| Best Use | Indoor maintenance | Construction & heavy-duty jobs |

| Mobility | Very easy | Moderate–heavy |

The numbers show that these lifts serve very different needs.

Performance Differences Explained

1. Lifting Capacity

Single man lift: lower capacity

Scissor lift: handles heavy tools, equipment, and multiple workers

If you need to carry heavy materials like ducting, panels, lights, or tools, the scissor lift wins.

2. Platform Space

Single man lifts offer just enough space for the operator and small tools.

Scissor lifts provide large platforms, often 2–3 times bigger.

3. Indoor vs Outdoor

Single man lifts overwhelmingly dominate indoor jobs.

Scissor lifts cover indoor electric models and outdoor rough-terrain varieties.

4. Maneuverability

Single man lifts are extremely nimble.

Scissor lifts require wider aisles and larger turning radius.

5. Floor Load

Single man lifts can safely operate on delicate floors like:

Shopping mall tiles

Marble flooring

Hospitals

Museums

Raised server floors

Scissor lifts may exceed floor load limits in some facilities.

6. Reach Type

Both lifts are strictly vertical-only.

If sideways reach is needed, a boom lift is the right choice instead.

Applications: Where Each Lift Works Best

Best Applications for Single Man Lifts

These lifts are optimized for tasks requiring mobility and space efficiency:

Warehouse equipment maintenance

Reaching high shelves and racking

Electrical and lighting repair

HVAC filter changes

Retail display installation

Hotel and mall cleaning

Airport signage service

Library or museum high-stack access

Their narrow design allows them to roll through standard doorways and elevators without folding or removing parts.

Best Applications for Scissor Lifts

Scissor lifts excel in heavier, more demanding tasks:

Construction and building installation

Large maintenance projects

Ceiling renovation

Industrial warehouses

Manufacturing plants

Outdoor repair work

High-bay lighting installation

Parking garage construction

Plasterboard, piping, and cable tray installation

Their larger platform supports teams working side by side.

Advantages of Single Man Lift vs Scissor Lift

Benefits of Single Man Lifts

Ultra-compact for confined spaces

Lightweight and easy to move

Minimal floor pressure

Cost-effective investment

Outstanding for routine indoor maintenance

Low noise and zero emissions

Passes through narrow aisles and doorways

Requires very little training

Their convenience makes them a modern replacement for ladders.

Benefits of Scissor Lifts

Higher load capacity

Larger working platform

Can lift multiple workers

More versatile in construction environments

Outdoor-capable models available

Strong stability at height

Greater lifting heights in heavy-duty designs

If productivity and platform size matter, scissor lifts lead comfortably.

Safety Comparison

Both lifts comply with global safety certifications such as CE, ANSI, and ISO.

Single Man Lift Safety Features

Emergency lowering

Anti-tilt sensors

Non-slip platform

Guardrails

Emergency stop

Automatic brakes

Overload detection

Their light weight and compact body reduce tipping risk in controlled indoor environments.

Scissor Lift Safety Features

Robust steel structure

Guardrails and toe boards

Emergency descent

Load sensing systems

Pothole protection

Outriggers (in some models)

Tilt alarms

Stronger chassis

Scissor lifts are safer for higher loads and multi-worker jobs.

Cost Comparison: Which One Is Cheaper?

Generally, single man lifts are significantly cheaper than scissor lifts.

Single Man Lift Price Range (2025)

| Height | Price (USD) |

|---|---|

| 4–6 m | $1,800 – $2,800 |

| 6–8 m | $2,200 – $3,500 |

| 8–10 m | $2,800 – $4,500 |

| 10–12 m | $3,500 – $5,000 |

| 12–14 m | $4,000 – $6,500 |

Scissor Lift Price Range (2025)

| Height | Price (USD) |

|---|---|

| 6–8 m electric | $5,000 – $8,500 |

| 8–10 m electric | $6,500 – $10,500 |

| 10–12 m electric | $7,800 – $12,000 |

| 12–14 m diesel | $12,000 – $20,000 |

| 14–18 m rough-terrain | $20,000 – $60,000 |

Single man lifts win overwhelmingly for buyers with limited budgets or routine maintenance needs.

Operational Cost Differences

Single man lifts have:

Lower electricity usage

Cheaper replacement parts

Fewer hydraulic components

Minimal annual maintenance

Scissor lifts require:

More frequent hydraulic maintenance

Higher battery consumption

More robust inspection cycles

Scissor lift operating costs can be 1.5–3 times higher annually.

Which Lift Is Better? Final Comparison Based on Usage

Choose a Single Man Lift If You Need:

Indoor maintenance

Work in tight aisles

A lightweight and portable lift

A safe alternative to ladders

Low upfront and maintenance costs

Easy movement through doors and elevators

One-person tasks without heavy tools

Single man lifts are unbeatable for everyday facility operations.

Choose a Scissor Lift If You Need:

Multiple workers on the platform

Heavy tools or supplies at height

Large surface installation

Construction or industrial work

Outdoor lifting capability

Higher platform heights

Stronger structural support

Scissor lifts are the workhorses for construction and heavy-duty jobs.

Future Trends: Why Many Companies Use Both

Large facilities increasingly adopt a hybrid aerial fleet:

Single man lifts for quick, repetitive daily tasks

Scissor lifts for heavy-duty periodic projects

This combined approach ensures maximum efficiency and cost control.

Facilities such as airports, logistics centers, and malls often use 3–10 single man lifts for routine tasks while renting or owning 1–2 scissor lifts for bigger maintenance or renovation projects.

Conclusion

The comparison between a single man lift vs scissor lift reveals two machines designed for very different purposes. A single man lift prioritizes mobility, low cost, quiet operation, and tight indoor access. A scissor lift focuses on high load capacity, multi-worker platforms, and both indoor and outdoor capability.

Neither lift is universally “better”—the right choice depends entirely on your tasks, environment, and budget. For facilities performing daily maintenance, a single man lift is the smartest, most cost-effective solution. For industrial and construction work requiring heavy loads and large platforms, the scissor lift remains essential.

If you’d like to explore next steps, categories like vertical mast lifts, push-around lifts, and rough-terrain scissor lifts offer useful extensions of this comparison.

812.webp)