A tracked scissor lift is a specialized aerial work platform designed for vertical lifting in challenging ground conditions where traditional wheeled scissor lifts struggle. By combining the vertical lifting mechanism of a scissor lift with a crawler track chassis, tracked scissor lifts deliver excellent stability, traction, and load capacity on soft, uneven, muddy, sandy, or sloped terrain.

As construction, infrastructure maintenance, and outdoor industrial projects continue to expand, tracked scissor lifts have become an essential solution for worksites that demand safe vertical access without ground preparation. This article provides a full introduction to tracked scissor lifts, including their structure, working principles, advantages, applications, specifications, safety features, and selection tips.

What Is a Tracked Scissor Lift?

A tracked scissor lift is a type of mobile elevating work platform (MEWP) that uses crawler tracks instead of wheels. The scissor mechanism raises the platform straight up, while the tracked undercarriage allows the machine to travel across rough or delicate surfaces.

Unlike boom lifts, which offer horizontal outreach, scissor lifts focus on vertical elevation with higher load capacity. The tracked configuration makes this equipment especially suitable for outdoor and off-road environments.

Tracked scissor lifts are often used where:

Ground is soft, muddy, sandy, or snowy

Terrain is uneven or sloped

Site access is limited or temporary

Ground pressure must be minimized

Key Components of a Tracked Scissor Lift

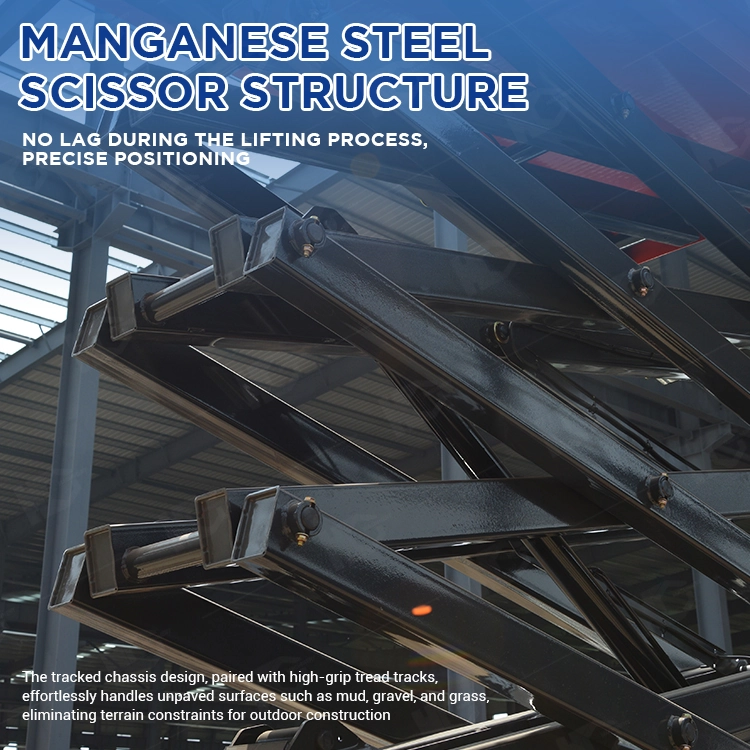

Scissor Lifting Structure

The scissor structure consists of crossed steel arms connected by pivot points. When hydraulic cylinders extend, the arms open vertically, lifting the platform in a straight line. This design provides:

High vertical stability

Large platform load capacity

Smooth and controlled lifting

Tracked Chassis (Crawler Undercarriage)

The crawler tracks replace traditional rubber or solid tires. They distribute machine weight over a larger surface area, reducing ground pressure and improving traction.

Benefits of crawler tracks include:

Strong grip on loose soil and gravel

Stable movement on slopes and uneven ground

Minimal damage to lawns or finished surfaces

Hydraulic System

Tracked scissor lifts use hydraulic power to drive:

Platform lifting

Track movement

Steering and braking

A well-designed hydraulic system ensures smooth operation, precise control, and reliable performance in demanding conditions.

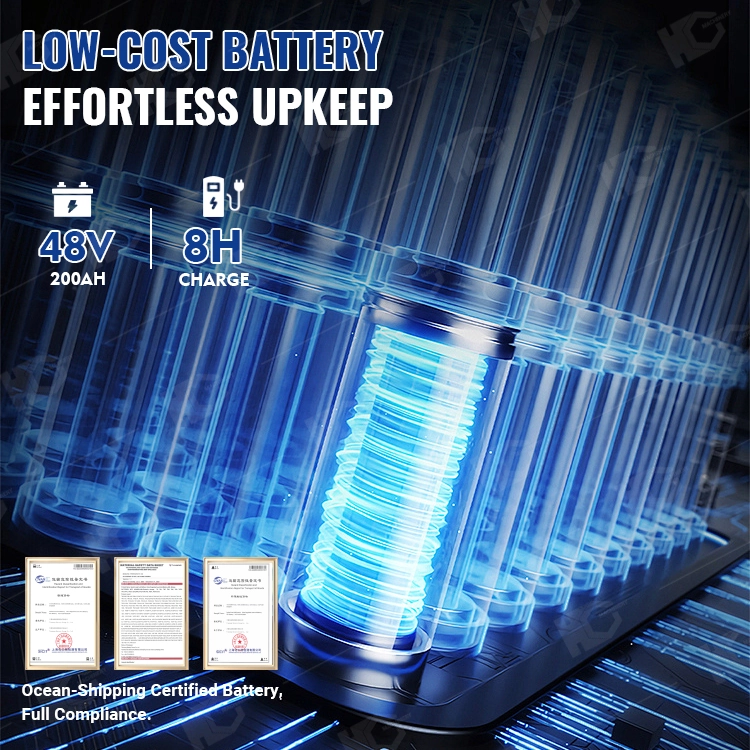

Power Options

Tracked scissor lifts are available in different power configurations:

Diesel-powered for heavy outdoor use

Battery-powered for low-noise or emission-sensitive environments

Hybrid systems combining battery and engine power

The choice depends on worksite regulations and operating duration.

Why Choose a Tracked Scissor Lift?

Superior Off-Road Capability

The primary advantage of a tracked scissor lift is its ability to operate on terrain where wheeled lifts cannot. Mud, sand, grass, snow, and gravel are no longer obstacles.

This makes tracked scissor lifts ideal for:

Outdoor construction sites

Landscaping and park maintenance

Utility and energy projects

Enhanced Stability and Safety

Crawler tracks provide a lower center of gravity and better weight distribution. This improves machine stability during lifting, especially on uneven ground.

Stability advantages include:

Reduced tipping risk

Better balance under load

Safer operation at maximum height

Low Ground Pressure

Tracked scissor lifts exert less pressure on the ground compared to wheeled machines. This helps protect:

Lawns and landscaped areas

Tile, brick, or sensitive surfaces

Temporary flooring systems

High Load Capacity

Compared to boom lifts, scissor lifts offer a larger platform and higher load capacity, allowing multiple workers, tools, and materials to be lifted simultaneously.

642934.webp)

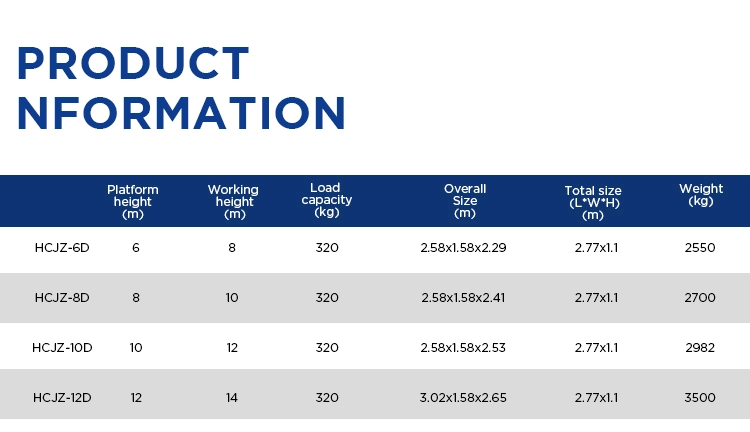

Typical Specifications of Tracked Scissor Lifts

While specifications vary by model, a typical tracked scissor lift includes:

Working height: 8–18 meters

Platform height: 6–16 meters

Load capacity: 230–450 kg

Platform extension: Optional sliding deck

Gradeability: Up to 25–30%

Track type: Rubber crawler tracks

These parameters make tracked scissor lifts suitable for both light-duty and heavy-duty applications.

Common Applications of Tracked Scissor Lifts

Construction and Building Maintenance

Tracked scissor lifts are widely used for:

Exterior wall installation

Steel structure assembly

Roofing and façade work

Their ability to move across unfinished ground reduces site preparation time.

Industrial Facilities and Plants

In industrial environments, tracked scissor lifts support:

Equipment installation

Pipe and cable routing

Facility maintenance

Battery-powered models are preferred indoors due to low noise and zero emissions.

Landscaping and Municipal Projects

For parks, gardens, and urban projects, tracked scissor lifts allow vertical access without damaging grass or soil. This makes them ideal for:

Tree trimming

Lighting installation

Signage and decoration

Energy and Utility Projects

Tracked scissor lifts are commonly used in:

Solar panel installation

Wind farm maintenance

Power line and utility infrastructure

Off-road mobility is essential in remote or undeveloped locations.

Tracked Scissor Lift vs Wheeled Scissor Lift

When comparing a tracked scissor lift with a wheeled scissor lift, the key difference lies in ground adaptability and operating environment. Tracked scissor lifts use crawler tracks that distribute weight evenly, providing excellent traction and stability on soft, muddy, sandy, or uneven terrain. This makes them ideal for outdoor construction sites, landscaping projects, and undeveloped areas where ground conditions are unpredictable. Their lower ground pressure also helps reduce surface damage and improves safety on slopes.Understanding the difference helps buyers choose the right equipment.

Tracked scissor lifts excel in:

Outdoor and off-road use

Soft or uneven ground

Sloped terrain

Wheeled scissor lifts are better for:

Smooth indoor floors

Warehouses and factories

Lower purchase and maintenance cost

Choosing between them depends on ground conditions and job requirements.

In contrast, wheeled scissor lifts are designed for smooth, hard surfaces such as concrete floors, warehouses, factories, and shopping malls. They are generally lighter, easier to transport, and require less maintenance than tracked models. Wheeled lifts also tend to be more cost-effective for indoor use and offer higher travel speeds on flat ground.

From an operational perspective, tracked scissor lifts prioritize stability and off-road performance, while wheeled scissor lifts emphasize efficiency and maneuverability in controlled environments. Choosing between the two depends largely on jobsite conditions rather than lifting height or platform capacity. For outdoor, rough-terrain applications, tracked scissor lifts offer superior reliability; for indoor or paved environments, wheeled scissor lifts remain the more practical and economical solution.

Tracked Scissor Lift vs Boom Lift

A tracked scissor lift and a boom lift are both widely used aerial work platforms, but they are designed to solve different access challenges. A tracked scissor lift specializes in vertical lifting, using a straight-up scissor mechanism combined with crawler tracks. This design provides excellent stability, high platform load capacity, and strong off-road mobility. It is ideal for jobs that require lifting multiple workers and heavy tools straight up, especially on uneven, muddy, or soft ground such as outdoor construction sites, infrastructure projects, and landscaping work.Tracked scissor lifts and boom lifts serve different purposes.

Tracked scissor lifts offer:

Vertical lift only

Higher platform load

Simpler operation

Boom lifts provide:

Horizontal outreach

Access over obstacles

Lower platform capacity

For straight-up work with heavy loads, tracked scissor lifts are more efficient and economical.

A boom lift, on the other hand, is built for reach and flexibility. Its articulated or telescopic arm allows both vertical and horizontal movement, making it possible to reach over obstacles, rooftops, machinery, or confined spaces. Boom lifts are better suited for tasks like façade maintenance, bridge inspection, and complex industrial installations where direct vertical access is not possible. However, boom lifts usually have lower platform load capacity and require more operator skill.

In summary, tracked scissor lifts are more efficient and cost-effective for straight vertical work on difficult terrain, while boom lifts excel when precise positioning and horizontal outreach are required.

354023.webp)

Safety Features of Tracked Scissor Lifts

Modern tracked scissor lifts are equipped with multiple safety systems, including:

Emergency stop buttons

Tilt and overload protection

Hydraulic safety valves

Non-slip platform flooring

Guardrails and toe boards

These features help protect operators and comply with international safety standards.

Maintenance and Service Considerations

Proper maintenance extends the service life of a tracked scissor lift.

Key maintenance points include:

Regular inspection of crawler tracks

Hydraulic oil and filter replacement

Checking pivot points and wear parts

Battery or engine servicing

Tracked systems require slightly more maintenance than wheeled units, but the operational benefits outweigh the added care.

How to Choose the Right Tracked Scissor Lift

When selecting a tracked scissor lift, buyers should consider:

Required working height

Platform load capacity

Indoor or outdoor use

Power source preference

Transport and storage requirements

Matching the lift to actual working conditions ensures better performance and lower total cost of ownership.

Advantages of Buying Tracked Scissor Lifts from Manufacturers

Purchasing directly from a tracked scissor lift manufacturer offers several benefits:

Factory-direct pricing

Customization options

Technical support and spare parts

Compliance with international standards

This is especially important for fleet buyers, rental companies, and contractors.

Future Trends in Tracked Scissor Lifts

The tracked scissor lift market is evolving toward:

Electric and hybrid power systems

Intelligent control and diagnostics

Lighter but stronger materials

Improved energy efficiency

These trends align with global demands for safety, sustainability, and productivity.

Conclusion: Why Tracked Scissor Lifts Matter

A tracked scissor lift is a powerful solution for vertical access in challenging environments. Its combination of strong lifting capacity, excellent off-road mobility, and enhanced safety makes it indispensable for modern construction, maintenance, and industrial projects.

For worksites where terrain limits conventional equipment, tracked scissor lifts provide reliability, efficiency, and peace of mind—lifting not just workers, but productivity itself.

812.webp)

344.webp)