A trailer-mounted boom lift—also known as a towable boom lift, tow-behind man lift, or portable articulated boom lift—is one of the most versatile aerial access machines in the market. It combines compact structure, lightweight towing design, and extended vertical/horizontal outreach to offer safe work-at-height performance in a remarkably portable form. For maintenance teams, contractors, electricians, tree-trimming companies, construction workers, and rental fleets, the trailer-mounted boom lift delivers a highly efficient solution without the high ownership cost of self-propelled booms.

This comprehensive guide explores the full product concept of trailer-mounted boom lifts, including technology, specifications, safety features, industry applications, configuration options, pricing structures, and how to select the right model for your business. Whether you are a distributor sourcing for your market, a rental company expanding your fleet, or an industrial buyer preparing for a 2025–2026 investment, this article will provide the insights you need to make an informed decision.

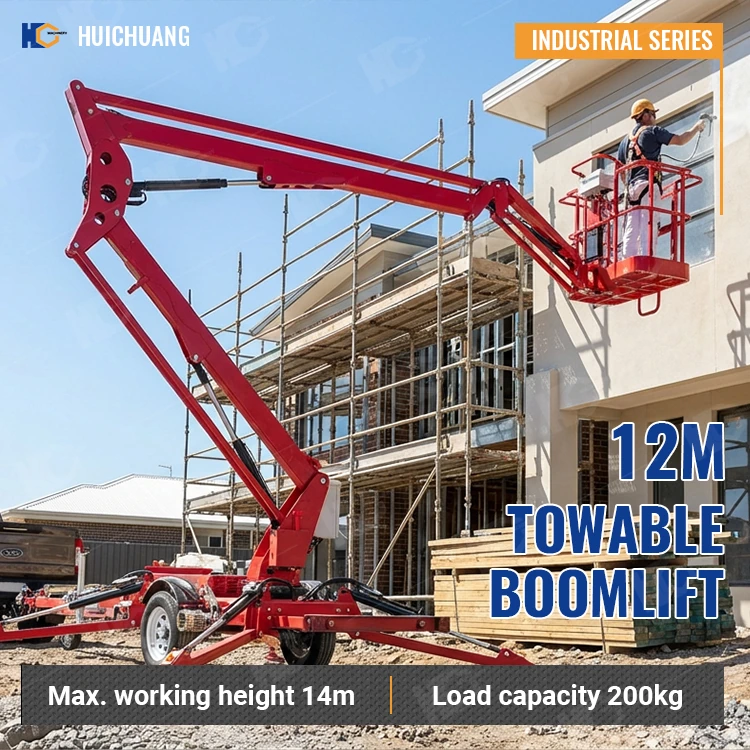

1. What Is a Trailer-Mounted Boom Lift?

A trailer-mounted boom lift is a lightweight aerial work platform designed to be transported using a standard vehicle equipped with a trailer hitch. Unlike traditional self-propelled boom lifts that rely on large chassis and drive motors, trailer-mounted models focus on portability and cost-efficiency while still offering impressive height capability.

Typical working heights range from 34 ft (10 m) up to 61 ft (18.5 m), and horizontal outreach commonly spans 12 ft to 30 ft, depending on the model and boom style.

A conventional trailer-mounted boom lift includes:

A trailer chassis with road-towable tires

A hydraulic articulated or telescopic boom

Outriggers for stabilization

A work platform (basket) for 1–2 operators

Hydraulic controls for smooth boom movements

A power system (battery, gasoline, diesel, or hybrid)

The machine is parked, leveled using outriggers, and operated safely with load-sensing and stability systems.

2. Major Advantages of Trailer-Mounted Boom Lifts

2.1 Easy Transportation

The number one advantage is mobility. Users can tow the boom lift with a pickup truck, van, or SUV. It eliminates the need for heavy transport or professional hauling services, which significantly lowers logistics costs.

2.2 Lower Purchase Cost

Compared with self-propelled booms, trailer-mounted units cost:

40%–65% less for similar heights

with lower maintenance and simpler hydraulic systems

This makes them ideal for small and medium-sized businesses, building owners, and rental companies.

2.3 Lightweight Structure

Most models weigh between 1,300–2,000 kg, which reduces:

Tire and ground pressure

Risk of damage on landscaped surfaces

Need for reinforced flooring indoors

Lightweight construction also improves towing efficiency.

2.4 Wide Working Height Options

Modern towable booms go up to 61 ft (18.5 m), making them suitable for:

Tree trimming

Exterior building maintenance

Sign installation and repairs

Higher warehouse lighting and overhead work

2.5 Safe and Stable Design

Hydraulic outriggers provide multi-point leveling and secure the lift during operation. Upgraded safety enhancements include:

Automatic leveling

Overload protection

Emergency lowering

Tilt alarms

Anti-entrapment systems

EN280 / ANSI compliance

2.6 Low Maintenance

There are fewer mechanical parts compared to self-propelled lifts:

No drive motors

No complex transmission

Lower tire wear

Simpler hydraulics

This translates into fewer breakdowns and lower ownership costs.

3. Types of Trailer-Mounted Boom Lifts

While many variations exist, they are generally categorized into two main types.

3.1 Articulating Trailer-Mounted Boom Lifts

These feature multiple boom sections connected by joints (articulations). Advantages include:

Ability to reach over obstacles

Excellent positioning flexibility

Ideal for tree work and building maintenance

They are the most common type worldwide.

3.2 Telescopic Trailer-Mounted Boom Lifts

These use straight-line extending booms.

Advantages include:

Longer horizontal outreach

Faster vertical access

Ideal for roofing, façade repair, and industrial work

Some hybrid models combine both articulating and telescopic functions.

4. Key Components and Technologies

4.1 Boom System

Made of high-strength steel, designed to provide rigid and stable movement. Manufacturers use robotic welding to ensure consistent structural integrity.

4.2 Outriggers

Automatic or semi-automatic outriggers enhance leveling stability. Sensors ensure proper deployment before the boom operates.

4.3 Power Options

Available configurations include:

Battery-powered (most popular for indoor/outdoor)

Gasoline engine

Diesel engine

Hybrid power combining electric with fuel engine

Electric versions offer zero-emission operation.

4.4 Control Systems

Control systems may include:

Proportional hydraulic valves

Electric-over-hydraulic joysticks

Emergency descent systems

Load-sensing management

Auto-return-to-home

Optional wireless remotes and diagnostic screens improve operator convenience.

5. Trailer-Mounted Boom Lift Specifications (General Reference)

Below is a reference-format specification sheet commonly used for 40–60 ft models. Actual data varies depending on manufacturer.

General Specifications Table

| Item | Typical Value / Range |

|---|---|

| Working Height | 34–61 ft (10–18.5 m) |

| Platform Height | 28–55 ft (8.5–16.7 m) |

| Horizontal Outreach | 12–30 ft (3.5–9 m) |

| Platform Capacity | 120–200 kg (1–2 persons) |

| Power Options | Battery / Gasoline / Diesel / Hybrid |

| Outrigger Leveling | Automatic or Manual |

| Transport Speed | Towed behind vehicle |

| Machine Weight | 1300–2000 kg |

| Rotation | 350°–360° non-continuous |

| Platform Size | 0.8 × 1.0 m or 0.8 × 1.2 m |

| Controls | Hydraulic or Electric/Hydraulic |

| Certification | CE, EN280, ANSI/SAIA A92 |

6. Applications of Trailer-Mounted Boom Lifts

6.1 Building and Facility Maintenance

Perfect for:

Exterior wall repair

Painting

Window cleaning

Gutter repair

Roof inspection

Lighting maintenance

Portable design makes it ideal for universities, hotels, hospitals, and large commercial properties.

6.2 Tree Trimming & Landscaping

The compact boom and flexible articulation allow operators to extend over branches safely. Landscapers value:

Light footprint

Easy maneuverability

Ability to work on soft ground

6.3 Electrical & Utility Work

Contractors use trailer-mounted booms for:

Overhead wiring

Streetlight repair

Security camera installation

Outdoor signage work

6.4 Construction & Renovation

Although not as robust as rough-terrain self-propelled booms, they work efficiently for:

Interior atrium work

Finishing tasks

MEP installation

Light fit-out operations

6.5 Rental Industry

This is one of the most profitable categories for rental fleets because:

Units are inexpensive

Transportation is simple

Maintenance costs are low

Utilization rates are high

7. Price Range of Trailer-Mounted Boom Lifts

Prices vary widely depending on brand, country of origin, working height, and power system.

7.1 Standard Market Pricing (Global Reference)

| Working Height | Price Range (USD) |

|---|---|

| 34–40 ft | $10,000–$15,000 |

| 45–50 ft | $15,500–$22,500 |

| 55–61 ft | $22,000–$34,000 |

| Hybrid / Battery | $26,000–$42,000 |

| Premium Western Brands | $35,000–$60,000 |

Factors influencing price include:

Height and outreach

Structural steel grade

Control system technology

Battery type

Brand reputation

8. Factors to Consider When Buying a Trailer-Mounted Boom Lift

8.1 Working Height Requirement

Always choose a model with excess height capacity. For example, if the highest working point is 45 ft, selecting a 50 ft unit is advisable.

8.2 Horizontal Outreach

Outreach is crucial when:

Reaching over awnings

Extending above obstacles

Working around landscaping features

Models with dual articulated booms offer superior positioning.

8.3 Indoor vs Outdoor Use

Indoor use often requires:

Electric power

Non-marking tires

Compact footprint

Outdoor use requires:

Stronger outriggers

Fuel engine options

Weatherproof electrical systems

8.4 Terrain Conditions

Trailer-mounted booms are ideal for:

Concrete

Asphalt

Packed soil

Not suitable for extreme rough terrain; tracked boom lifts outperform them there.

8.5 Power System Choice

Battery-powered lifts suit:

Low-noise environments

Indoor malls

Residential areas

Gasoline or hybrid units offer extended operation for outdoor construction.

8.6 After-Sales Support

Look for:

Factory-trained technician availability

24/7 remote diagnostic service

Readily available spare parts

1–2 year standard warranty

8.7 Certification

Depending on your country or market:

Europe: CE / EN280

USA: ANSI/SAIA A92

Australia: AS 1418

Middle East: Third-party inspection required

Certified machines maintain higher resale value.

9. Trailer-Mounted Boom Lift Manufacturing Process Overview

A well-engineered lift follows these core manufacturing stages:

9.1 Steel Cutting and Robotic Welding

High-strength boom sections are plasma-cut and robot-welded for consistent structural durability.

9.2 Machining & Fabrication

Turntable

Outrigger arms

Brackets

Platform frame

Precision machining ensures accurate assembly.

9.3 Assembly of Hydraulics

Technicians install:

Cylinders

Hoses

Valves

Manifolds

Pump motors

Hydraulic testing ensures leak-free operation.

9.4 Electrical System Installation

Wiring harnesses, safety switches, and controllers are fitted.

9.5 Final Assembly

Boom, chassis, outriggers, and basket are combined.

9.6 Load Testing & Quality Control

Every unit undergoes:

Overload testing

Tilt testing

Stability tests

Function tests

Electrical safety verification

This ensures compliance with international safety standards.

10. Comparison: Trailer-Mounted vs Self-Propelled Boom Lift

Trailer-Mounted Advantages

Lower purchase cost

Easier to transport

Lower maintenance

Lighter weight for soft ground

Better for rental companies

Self-Propelled Advantages

Faster travel on job site

Better rough terrain performance

Higher duty cycle

Greater platform capacity

Trailer-mounted units are more economical, but self-propelled booms dominate heavy construction.

11. Common Accessories and Optional Features

11.1 Platform Accessories

Rotating basket

Tool trays

Platform work lights

Air/water line to platform

11.2 Power and Control Options

Lithium battery packs

Wireless remote control

Automatic home return

11.3 Safety Enhancements

Anti-entrapment system

Emergency descent battery backup

11.4 Custom Paint and Branding

For rental fleets or manufacturers with OEM/ODM programs.

12. Maintenance Requirements

Maintaining a trailer-mounted boom lift is relatively simple.

12.1 Weekly Checks

Hydraulic oil level

Tire pressure

Visual inspection of hoses

12.2 Monthly Maintenance

Grease pivot points

Inspect electrical wiring

Test emergency descent

12.3 Annual Service

Replace hydraulic oil and filters

Inspect boom wear pads

Test load-limiting system

Recalibrate sensors if needed

Proper maintenance extends equipment life and preserves resale value.

13. Trailer-Mounted Boom Lift for Rental Companies

Rental companies love towable booms because they offer:

High demand

Low purchase price

Quick payback (6–12 months)

Easy transport between jobs

Low cost-per-hour maintenance

Typical rental prices:

Daily: USD 120–220

Weekly: USD 450–750

Monthly: USD 1,200–2,000

Towable booms often achieve utilization rates above 60%, making them very profitable.

14. How to Import Trailer-Mounted Boom Lifts from China

China is a global leader in hydraulic aerial equipment production. Importing from a reliable factory requires attention to several steps:

14.1 Review Certifications

CE, EN280, ANSI options should be available.

14.2 Confirm Production Lead Time

Lead time usually ranges:

20–35 days for standard models

45–60 days for customization

14.3 Inspect Quality Control Documents

Request:

Test videos

Inspection reports

Load test certificates

14.4 Shipping

Most units are shipped by:

20 ft container (1–2 units)

40 ft HQ container (3–4 units)

14.5 After-Sales Service

Choose factories offering:

Spare parts package

Technical manual

Online support

Imports typically cost 30–45% less than EU/US-made units.

15. Final Buying Recommendations

A trailer-mounted boom lift is a valuable investment for companies seeking safe, portable, and cost-efficient access equipment. To choose the right model, focus on:

Working height

Outreach

Power system

Stability and safety features

After-sales service

Certification

Price-to-performance ratio

With proper evaluation, buyers can secure a lift that delivers long-term performance and strong return on investment.