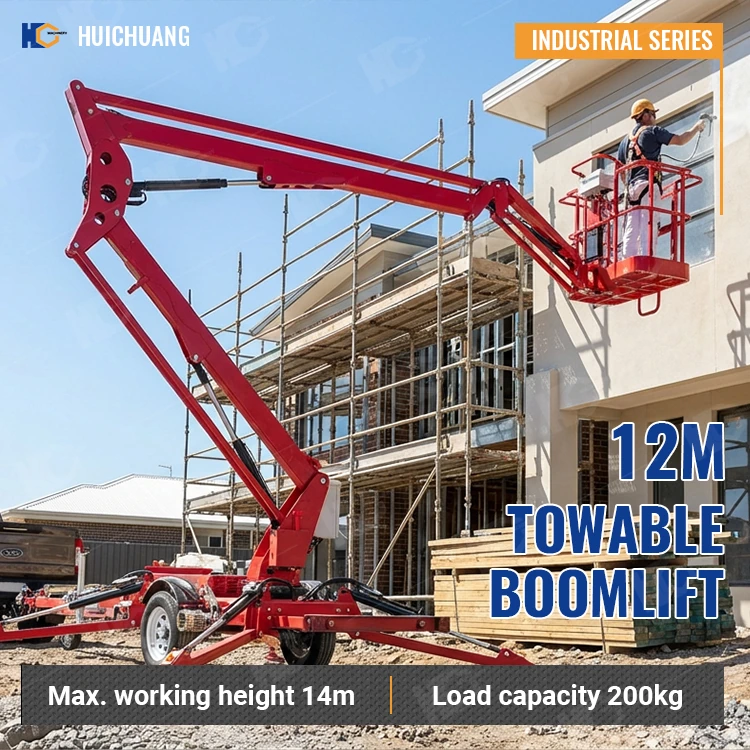

Boom Lifts product brochure made in China

1. Product classification and size parameters

1. Classification by structure type

Models | Typical working height | Platform size | Stretch length | Chassis width | Folded Dimensions (L×W×H) | Weight range |

Scissor | 8-12m | 1.2×0.8m | No outrigger | 0.8m | 2.1×1.2×2.4m | 1,200-1,800kg |

Curved arm type | 10-18m | 1.5×1.0m | Horizontal extension 4m | 1.0m | 3.0×1.2×2.8m | 2,000-2,800kg |

Straight arm type | 16-40m | 1.8×1.2m | Horizontal extension of 12m | 1.2m | 4.5×1.5×3.2m | 3,500-5,500kg |

2. Comparison of standard sizes (taking the mainstream curved arm type as an example)

Parameter items | Domestic standard model(JG-18) | International competitor (Genie Z-18) |

Maximum height | 18.3m | 18.5m |

Platform bearing | 300kg | 280kg |

Collapse height | 2.8m | 3.0m |

Stretch horizontally | 7.5m (3-segment arm) | 7.2m (2-segment arm) |

Chassis width | 1.05m | 1.1m |

Volume after folding | 3.0×1.2×2.8m | 3.2×1.3×3.0m |

As an important player in the global aerial work equipment market, Chinese manufacturers have broken through traditional technical barriers through precise modular design. From scissor-type to straight-arm type, the differentiated positioning of different models in terms of operating height, platform size and transport adaptability have jointly built a solution system covering all scenarios. The following will deeply analyze the core technical parameters that support these product features, revealing the dual breakthroughs of Chinese manufacturing in efficiency and reliability.

The core technical parameters

1. Structural parameters

Boom material: high-strength Q345B steel (yield strength≥345MPa).

Hydraulics:

o Working pressure: 24 MPa

o Flow rate: 32 L/min

o Cylinder stroke: main boom 6.5m (telescopic stroke)

Power configuration:

type | Domestic diesel engine (Yuchai 100kW) | Electric version (CAT battery pack) |

Rated power | 100kW@2,200rpm | 90kW (48V/200Ah lithium battery) |

Endurance | 8 hours of continuous operation | 6 hours (1.5 hours for fast charging) |

2. Safety devices

Anti-overturning system: 3-axis gyroscope real-time monitoring (sensitivity 0.1°).

Overload Protection: Load Cell (Accuracy±0.5%FS).

Emergency descent: two-stage hydraulic lock-out valve (response time<0.3s).

378450.webp)

Based on a deep insight into global market demand, telescopic boom lifts made in China have achieved technological breakthroughs in three core areas: hydraulic systems, power configurations, and safety devices. Taking Q345B high-strength steel and intelligent temperature control systems as an example, they not only meet the extreme working conditions of the hot and humid environment in Southeast Asia and the high temperature in the deserts of the Middle East, but also lay the foundation for subsequent application scenario adaptation through modular design concepts.

Typical application scenarios and size adaptation

1. Construction Works (High Priority)

Applicable model: straight arm type (JG-32).

Size advantage:

o The working height is 32m, covering the exterior wall of the 10-storey building

o After folding, the length is 4.5m, suitable for standard 40HQ containers (inner diameter 12m× 2.35m×2.39m)

Case study: Shanghai Tower façade maintenance project

2. Power maintenance (space constraints)

Applicable model: Curved arm type (JG-15C).

Dimensional characteristics:

o The height of the retract is 2.8m, and the construction site gate is 3m wide

o The platform rotates 360° to adapt to the narrow substation environment

Data: When the horizontal extension is 4.2m, the clearance above the ground ≥ 6.5m

3. Logistics and warehousing (efficient operation)

Applicable model: scissor type (JNHC-10H).

Space Optimization:

o The width of the chassis is 1.0m, which is suitable for the 1.1m passage between the shelves

o The lifting speed is 0.35m/s, which can meet the needs of high-frequency cargo access

859814.webp)

The breakthrough in technical parameters ultimately serves the needs of scenarios. When the straight-arm model covers the outer wall of a 10-story building at a working height of 32m, its compact size of 4.5m after folding corresponds to the standardized transportation needs of a 40HQ container; and the 360° rotation capability of the articulated-arm model in power maintenance scenarios is derived from the collaborative innovation of the hydraulic system and structural design. The following cases will demonstrate how these technical features are transformed into commercial value.

The core advantages of Made in China

1. Modular design

Boom connection: patented quick-release interface (installation time< 30 minutes).

Transportation optimization: 35% reduction in volume after folding (compared with similar products in Europe and the United States).

Universal accessories: The cylinder/battery pack is compatible with 3 series of models

2. Intelligent control system

Operation interface: 7 inch LCD touch screen (support multi-language switching).

Automatic leveling: ± 1° accuracy, adapt to the slope ≤5° site

Remote diagnosis: The 4G module transmits fault codes in real time (covering the network of 120 countries around the world).

3. Cost-effective

Cost items | Domestic models | Imported models | Rate of discrepancy |

Acquisition costs | $85,000–120,000 | $150,000–200,000 | 40%↓ |

Maintenance Costs (Annual) | $3,200 | $8,500 | 62%↓ |

Depreciation period | 8 years | 6 years | 33%↑ |

From vertical maintenance of the Shanghai Tower to desert operations at Saudi Aramco oil fields, China's aerial machinery is reshaping industry standards with "technological popularization". By reducing transition time by 35% through patented quick-release interfaces and achieving global service response through 4G remote diagnostic systems, Chinese manufacturing is breaking through the inherent perception of "high price and high quality". This high cost-effectiveness is quantitatively confirmed in the following cost comparison.

The selection guide and size matching

1. Height-to-stretch ratio formula

Effective height = arm length ×cos(θ) + platform height

· Recommended parameters: θ=75°, the best extension efficiency (arm length utilization rate ≥82%)

2. Site Size Matching Table

Job scenario | Required platform size | Recommended model | Minimum working radius |

Curtain wall installation | 1.2×0.9m | JNHC-18 curved arm | 4.5m |

Tree pruning | 1.0×0.8m | JNHC-12 scissors | 3.2m |

Equipment hoisting | 1.5×1.2m | JNHC-25 straight arm | 6.8m |

Technical advantages need to be transformed into precise engineering adaptation. When the 75° extension angle maximizes the arm length utilization, it is behind the coordinated operation of the 3-axis gyroscope and the automatic leveling system; and the adaptation of the 1.0m chassis width to the 1.1m shelf channel relies on the rapid reconstruction capability of the modular arm. This section will guide users to complete scenario-based selection decisions through mathematical models and measured data.

International certification and packaging solutions

1. Certification Standards

CE marked: EN 1808:2019 (dynamic load test 1.5 times).

ISO standard: ISO 9241-420 (ergonomic design code).

Environmental certifications: RoHS (lead content < 0.1%), REACH (SVHC list compliance).

2. Export packaging scheme

Folded size: 4.5×1.5×3.2m (suitable for 20HQ containers).

Shockproof design:

o Hydraulic cylinder with silicone cushion (50 Shore A)

o Boom wrapping EPE styrofoam strip (density 35kg/m³)

Moisture-proof measures: silica gel desiccant (moisture absorption ≥ 300g) is placed in the container

Technological leadership requires the endorsement of international standards. The 1.5 times dynamic load test of CE certification and the environmental protection requirements of RoHS not only verify the reliability of the product, but also provide compliance guarantees for exports to the hot and humid areas of Southeast Asia and the desert environment of the Middle East. This technical compliance is directly reflected in the shockproof and moisture-proof design of the export packaging, ensuring that the equipment maintains performance stability during long-distance transportation.

Typical customer cases

Case 1: Southeast Asia Telecom Tower Maintenance

For the maintenance of base stations in hot and humid climates (average annual humidity of 85% and temperature of 35-42°C), JNHC-18 crank arm lift (18m working height) with IP67 protection motor is used. The equipment is equipped with Dacromet anti-corrosion treatment, silicone rubber cable and dual-fan cooling system to adapt to salt spray corrosion and high temperature environment. Equipped with an intelligent temperature control module, real-time monitoring of oil temperature and automatic frequency reduction protection, it achieves an average of 7.2 hours of efficient operation per day, with an average monthly maintenance area of 6,000m² and a failure rate of less than 0.5%. The technological breakthrough has extended the life of the equipment by 30% and reduced the maintenance cost by 65%, becoming a benchmark case of aerial work in hot and humid areas in ASEAN, and helping China's aerial machinery export market share increase by 12%.

Case 2: Middle East oil storage tank inspectionIn

View of the storage tank detection requirements of extreme high temperature in the desert (average daily 55°C, the peak temperature of the surface of the equipment reaches 82°C), the JNHC-25 straight arm lift (32m working height) is equipped with a dual air cooling system (the heat dissipation efficiency is increased by 40% compared with the conventional one). The equipment achieves a continuous 4-hour operating oil temperature of ≤85°C by strengthening the design of the heat dissipation chamber (fin density increased by 25%), high-temperature resistant hydraulic oil (flash point ≥ 320°C) and IP69K protective motor. Equipped with an intelligent thermal management module, the fan speed and hydraulic flow can be adjusted in real time to ensure the stable operation of the equipment in the high-temperature environment of Saudi Aramco oilfield, with a single detection efficiency of 1,200 square meters per hour, and the failure rate is reduced by 58% compared with imported models, becoming a benchmark case for China's high-altitude machinery to break through the Middle East market.

The globalization process of China's aerial machinery has reached new heights with the dual breakthroughs in the extreme markets of humidity and high temperature. From the average monthly operating efficiency of 6,000m² in the Vietnam Telecom Tower Maintenance Project to the 58% reduction in the failure rate of the Saudi tank inspection case, these data confirm the commercial transformation capabilities of the technical parameters and design concepts mentioned above.

After-sales service system

Global service network: covering 120 countries, the average response time < 24 hours

Spare parts supply: The inventory cycle of key components ≤ 7 days (support DHL emergency air freight).

Technical training: VR simulation operating system (12 standard training modules) is available

289252.webp)

The ultimate manifestation of product competitiveness lies in building a service network covering the entire life cycle. When the VR simulation training system reduces the operating error rate by 40%, its value comes from the maintainability of the modular design mentioned above; and the 72-hour global spare parts supply supported by DHL forms a closed loop with the standardized design of the patented quick-release interface. Made in China is completing the transition from product output to technical standards through service innovation.

With its precise dimensional design, reliable power system and cost-effective advantages of Made in China, this product series has become the mainstream choice in the global aerial work equipment market. Through modular expansion and intelligent upgrade, it can meet the needs of all scenarios from simple maintenance to complex engineering.