In industries such as construction, power maintenance, and advertising installation, medium-high altitude operations (10-20 meters) have long presented a dual challenge of efficiency and safety. Traditional scaffolding is time-consuming and labor-intensive to erect, vehicle-mounted aerial platforms are limited by site access constraints, and the portability needs of single-person operations are often overlooked. Against this backdrop, the 18m hydraulic trailer-mounted single-person scissor aerial work platform (hereafter referred to as the "18m hydraulic trailer scissor platform") has emerged as an "all-round star" in medium-high altitude operations, thanks to its innovative design integrating hydraulic drive, trailer chassis, and single-person operation. This article delves into the technical principles, core advantages, application scenarios, and procurement considerations of this equipment, providing a comprehensive analysis of its market value and practical significance.

Hydraulic trailer single man scissor lift is a mobile aerial work platform, it can carry 300kg - 2000kg weight to 4m - 18m height. Here I will introduce the details of 18m single man scissor lift.

Hydraulic trailer single man scissor lift weight 18m can reach to 18m height for some aerial work, such as glass curtain wall repair, wall painting and etc. One single man can operate it to go up or go down, it can carry maximum 2000kg, the most popular model is 300kg basic model. This single man scissor lift weight is heavy, usually it needs a trailer move it from warehouse to the work site. But for short distance move, we have an optional function called walking assist device, it is like we add a motor on the rear wheels, so it can drive the wheels and make the whole scissor lift move.

Model | Platform Size | Load Capacity | Lifting Height (m) | Overall Dimensions (mm) | Extended Platform | Machine weight |

HC-6B | 1730*740 | 200 | 6 | 1910*780*2120 | 0.9 | 1430 |

HC-6 | 2270*1110 | 320 | 6 | 2470*1150*2200 | 0.9 | 2200 |

HC-8 | 2270*1110 | 320 | 8 | 2470*1150*2320 | 0.9 | 2350 |

HC-10 | 2270*1110 | 320 | 10 | 2470*1150*2430 | 0.9 | 2600 |

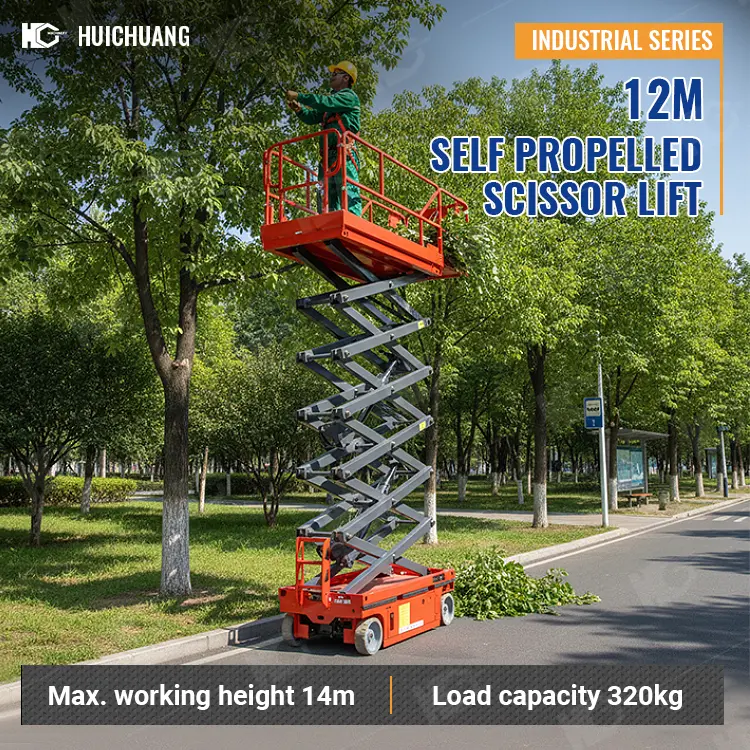

HC-12 | 2270*1110 | 320 | 12 | 2470*1150*2550 | 0.9 | 2850 |

HC-14 | 2640*1120 | 230 | 14 | 2850*1250*2640 | 0.9 | 3300 |

HC-16 | 2260*1130 | 320 | 16 | 3150*1530*2350 | 0.9 | 3880 |

The hydraulic scissor lift 18m can be divided into 3 parts, top platform part, scissor structure part and bottom chassis part.

1. Top platform

This part includes the high strength guardrail, antislip platform and top control button. The operator can control the 18m hydraulic scissor lift from the top platform part.2. Scissor structure

This is the main lifting structure, the cylinder pushes this structure extend, then the scissor lift will go up. The axle pins have lube in it to make it more smooth, and the pins need to be added lube regularly.

Actual customer pictures

3. Bottom chassis

There is a control button on the bottom chassis, you can also control the scissor lift from this button. The main power switch is on the chassis, please remember to open it before you use this machine. The most important thing before you go up is that the scissor lift has to be leveling. You can adjust the leveling with 4 outriggers and check the angle with the bubble level. The pump station and control box are inside of the chassis, we get a steel cover to protect these 2 important parts.

control button

After acknowledge the structure of single man scissor lift, you may be curious about how to use it. It is simple, turn on the main power switch, open 2 emergency stop button on the platform control and chassis control, adjust the scissor lift to be leveling, then go up to the height you want. The standard power of hydraulic mobile scissor lift is AC (Alternating Current), the voltage and plug can be customized according to your country standards. And we have DC (Direct Current) battery power as an option. If the working site is far from the socket, or it’s inconvenient and unavailable to use the electric wires, you can choose battery power. The charger voltage also can be customized, and the charger has charging protection, it won’t be overcharged.

I. 18m Hydraulic Trailer-Mounted Single-Person Scissor Platform: The Technical Core Redefining "Medium-High Altitude Operations"

1. Basic Definition and Structural Composition

The 18m hydraulic trailer-mounted single-person scissor platform is a medium-high altitude work device that uses hydraulic systems to drive scissor mechanisms for vertical lifting and a trailer chassis for flexible mobility. Its core structure comprises three modules:

Power and Lifting System: An onboard hydraulic pump station (typically electric or diesel-powered) drives hydraulic cylinders to extend/retract scissor arms, raising the platform from its folded state (minimum height ~2m) to a maximum working height of 18m.

Trailer Chassis: Constructed from high-strength steel frames with off-road/highway dual-use tires (e.g., polyurethane or pneumatic rubber wheels), it supports movement via trailer hitch connection to trucks for long-distance transport or short-distance maneuvering (some models include auxiliary wheels).

Single-Person Operator Cabin: The platform’s work surface typically measures 1.2m×0.8m (customizable for wider models) and supports 1-2 operators (some models limit to 1 person). It integrates a control panel (joystick/buttons), safety railings, and tool attachment points.

2. Key Technical Parameters (Industry Mainstream Configurations)

| Parameter | Description |

|---|---|

| Maximum working height | 18m (platform height above ground when scissor arms are fully extended) |

| Maximum platform load | 230kg–300kg (single-person operation primarily, with capacity for light tools/materials) |

| Lifting speed | 0.1–0.3m/s (hydraulically adjusted for smooth, impact-free operation) |

| Trailer mobility speed | 0–5km/h (highway mode); 0–3km/h (off-road/rough terrain) |

| Power type | Electric (48V/80V DC motor + lithium battery, suitable for indoor/campus use); Diesel (1.5L–2.2L displacement, suitable for outdoor use) |

| Gradeability | ≤15° (electric); ≤25° (diesel) |

| Tire type | High-elastic polyurethane wheels (indoor/outdoor); pneumatic rubber wheels (gravel/dusty sites) |

| Safety features | Anti-tipover sensor (automatic shutdown at tilt >5°), overload alarm, emergency stop button, automatic braking, and spirit level |

II. Why the 18m Hydraulic Trailer Scissor Platform is the "Optimal Solution" for Medium-High Altitude Operations?

1. Flexibility: A "Mobile Workstation" Breaking Site Limitations

Traditional vehicle-mounted aerial platforms (e.g., cherry pickers) reach higher heights (20–50m) but rely on large chassis, limiting them to urban roads or open spaces. Fixed elevators cannot move at all. The 18m hydraulic trailer scissor platform solves this contradiction with its trailer chassis design:

Short-distance mobility: No external power or cranes needed; a single worker can push the platform through stairwells, narrow passages, and other confined areas.

Long-distance transport: Towing via truck enables easy cross-site/region transfers (e.g., from Project A to Project B with a single loading/unloading).

Multi-scene adaptability: Tires can be customized (polyurethane for indoor/outdoor, pneumatic rubber for rough terrain, or snow tires for winter operations in northern regions).

Case Study: When an advertising company replaced LED screens on the exterior walls of shopping malls in an urban commercial area, using the 18m hydraulic trailer scissor platform instead of traditional scaffolding increased daily work area from 80㎡ to 200㎡. It also avoided dismantling temporary barriers around the mall, saving 3 days of construction time.

2. Efficiency: Single-Person Operation + Rapid Lifting as a "Time-Saving Wizard"

Labor waste is a core pain point in medium-high altitude operations—traditional scaffolding requires 2–3 workers to erect for 2 hours, while mobile platforms demand specialized operators and slow movement. The 18m hydraulic trailer scissor platform boosts efficiency through three key designs:

Single-person control: Integrated "lift + mobility" dual controls (joystick/remote) allow one worker to complete the entire workflow: "move-position-lift-work."

Rapid lifting: Hydraulic systems respond quickly (6–10 minutes to ascend from ground to 18m) and support "hover lifting" (no need to repeatedly raise/lower for adjustments like billboard angle tuning).

Ready-to-use: No assembly/disassembly required (traditional scaffolding takes 4 workers 2 hours to erect), enabling immediate deployment and removal post-job.

Data Comparison: For exterior wall cleaning of 10 high-rise residential buildings, a property company using the 18m hydraulic trailer scissor platform (1 worker) took 15 days, while traditional scaffolding (3 workers erecting + 2 workers cleaning) took 28 days—an efficiency improvement of nearly 90%.

3. Safety: From "Passive Protection" to "Active Early Warning" Technological Upgrades

Safety incidents in medium-high altitude operations often stem from "operator errors" or "equipment failures." The 18m hydraulic trailer scissor platform constructs a "dual protection network" through four safety innovations:

Structural safety: Scissor arms are made of Q345B manganese steel (tensile strength ≥470MPa), with reinforced ribs at critical joints to ensure stability at 18m heights.

Intelligent protection: Equipped with anti-tipover sensors (real-time monitoring of platform levelness, auto-shutdown at tilt >5°), overload alarms (beeping and locking lifts at >230kg), emergency stop buttons (1-second power cutoff), and automatic brakes.

Dynamic stability: Four-wheel independent suspension reduces jolts during movement; hydraulic systems include balance valves to prevent platform slippage due to cylinder leakage.

Emergency safeguards: Standard manual pressure relief valves (slow platform descent during power outages) and backup batteries (electric models) or emergency fuel pumps (diesel models) ensure safe worker evacuation in extreme scenarios.

Industry Certification: Mainstream brands comply with CE (EU), ANSI (USA), or GB 25849-2010 (China) safety standards; some models additionally hold "Aerial Work Platform Safety Star" certifications.

4. Cost-Effectiveness: Lower Lifecycle Costs Than "Scaffolding + Labor" Combinations

While the initial purchase cost of an 18m hydraulic trailer scissor platform (~¥80,000–¥150,000) exceeds that of traditional scaffolding (~¥20,000–¥30,000), its lifecycle cost (LCC) advantage is significant:

Labor cost: Single-person operation reduces labor requirements by 50% (e.g., cleaning 1 building shifts from 6 workers×2 days → 1 worker×1 day), cutting wage expenses.

Maintenance cost: Hydraulic systems last 8,000 hours (5+ years with 4 hours/day use), far outlasting scaffolding’s "disposable" consumption (15% annual loss of steel pipes/fittings).

Space cost: Eliminates scaffolding setup, avoiding venue rental fees or resident compensation for blocked spaces (e.g., mall atriums, community gardens).

Cost Analysis: For a company with 500 annual medium-high altitude operation hours, using the 18m hydraulic trailer scissor platform (¥100,000 purchase + ¥10,000/year maintenance) totals ¥110,000/year. Traditional scaffolding + labor (¥30,000/year setup + ¥80,000/year labor) also totals ¥110,000/year—but the former’s 50% efficiency gain delivers higher actual returns.

III. Typical Application Scenarios of the 18m Hydraulic Trailer Scissor Platform

1. Construction and Municipal Maintenance

Exterior wall operations: Paint spraying, glass curtain wall cleaning, and tile repair (18m height covers 3–6 story residences or 2–4 story commercial buildings).

Public facility maintenance: Streetlight repairs (no cherry picker needed), bus shelter rust removal, and bridge railing inspections (trailers navigate along temporary roadside paths).

2. Industrial and Warehouse Scenarios

Factory equipment maintenance: Ventilation pipe inspections in workshop ceilings, production line high-level instrument calibration (no fixed scaffolding required).

Warehouse high-altitude work: Top-shelf goods access (paired with pallet jacks) and roof insulation layer checks (platforms hug roof edges).

3. Commercial and Community Services

Commercial space operations: LED screen replacements and central AC unit cleaning in malls (trailers maneuver through narrow streets).

Community facility maintenance: Elevator machine room repairs and fire pipe inspections (no hallway closures, minimizing resident disruption).

4. Emergency and Specialized Operations

Fire rescue: Paired with ladder trucks to provide transfer platforms for low-rise (<18m) trapped individuals.

Power repairs: Lightning rod inspections on distribution house roofs and high-voltage pole base equipment maintenance (trailers position near poles).

IV. 10 Key Considerations for Bulk Procurement of 18m Hydraulic Trailer Scissor Platforms

For enterprises or rental companies, bulk procurement requires balancing "operational needs, cost, and after-sales support." Below are critical decision points:

Clarify operational scenarios:

Indoor use (e.g., malls, workshops) prioritizes electric models (noise-free, zero emissions).

Outdoor/construction sites select diesel models (longer range, rough terrain adaptability).

Narrow spaces (e.g., stairwells, communities) require compact platforms (width ≤1m).

Power system matching:

Electric models need charging infrastructure (e.g., workshop chargers).

Diesel models must comply with emission standards (National IV/Euro V) to avoid regulatory restrictions.

Mandatory safety configuration checks:

Anti-tipover sensors, overload alarms, and emergency stop buttons are non-negotiable.

High-altitude regions (>2,000m) require highland hydraulic pumps (prevents power attenuation).

Trailer chassis adaptability:

Highway transport requires platform dimensions to fit truck beds (length×width ≤6m×2.5m).

Off-road scenarios demand reinforced chassis (self-weight ≥800kg to prevent getting stuck).

After-sales network coverage:

Prioritize brands with service centers in target regions (e.g., East, South, North China).

Confirm warranty terms (core components ≥2 years; hydraulic systems ≥3 years).

Customization needs assessment:

Evaluate requirements for protective railings (fall prevention) or tool brackets (efficiency boosts).

Check support for platform extensions (e.g., +1m length to expand work scope).

Operator training support:

Require manufacturers to provide "theory + hands-on" training (≥8 hours).

Ensure training materials cover "complex terrain operation" and "emergency troubleshooting."

Logistics and delivery timelines:

Confirm production cycles (standard models: 4–6 weeks; customized models: 8–10 weeks).

Clarify logistics responsibilities (delivered to site vs. self-pickup; remote area freight costs).

Consumable cost accounting:

Hydraulic oil replacement intervals (typically 2,000 hours; ~¥500 per change).

Tire wear rates (polyurethane wheels: ~5,000 hours; pneumatic tires: ~3,000 hours).

Contract term refinement:

Define fault response times (24-hour on-site arrival; 48-hour repairs).

Specify "human-induced damage" criteria (e.g., operator error causing scissor deformation not covered by warranty).

V. Future Trends: Intelligent Upgrades for 18m Hydraulic Trailer Scissor Platforms

With the integration of industrial internet and AI technologies, 18m hydraulic trailer scissor platforms are evolving from "mechanical tools" to "intelligent terminals":

Remote monitoring: IoT modules enable real-time device tracking (location, fuel level, fault codes) via mobile apps.

Automatic leveling: Integrated inclinometers + automatic hydraulic adjustment systems enable platforms to self-level without manual intervention.

Voice control: High-end models now support voice commands ("forward/backward/ascend"), further lowering operational barriers.

Conclusion

The 18m hydraulic trailer-mounted single-person scissor aerial work platform, with its "hydraulic-driven stability + trailer chassis flexibility + single-person operational efficiency," has precisely addressed the pain points of medium-high altitude operations. Whether in construction maintenance, industrial production, or commercial services, it has become an indispensable "all-round tool" for boosting efficiency, reducing costs, and ensuring safety. For enterprises, selecting a scenario-adaptive, reliable, and well-supported 18m hydraulic trailer scissor platform represents not just equipment upgrades but a transformation in operational models and management capabilities.

Hydraulic trailer single man scissor lift weight 18m is an economical aerial work platform for working high above the ground. 18m platform height means 20m working height, it can meet most of the aerial work requirements. We are a professional scissor lift manufacturer, besides single man scissor lift, we also have other hydraulic aerial work platform such as mast lift, boom lift, cargo lift and etc. We accept OEM and ODM production, if you have any special requirements, welcome to contact us.